Phase change temperature control vacuum tube anti-explosion booster water heater

A technology of phase change temperature control and vacuum tubes, which is applied to solar collectors using working fluids, solar collectors, solar collector heat insulation, etc., can solve problems such as heat collection efficiency that is prone to bursting, and improve heat collection efficiency , the effect of increasing water temperature and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

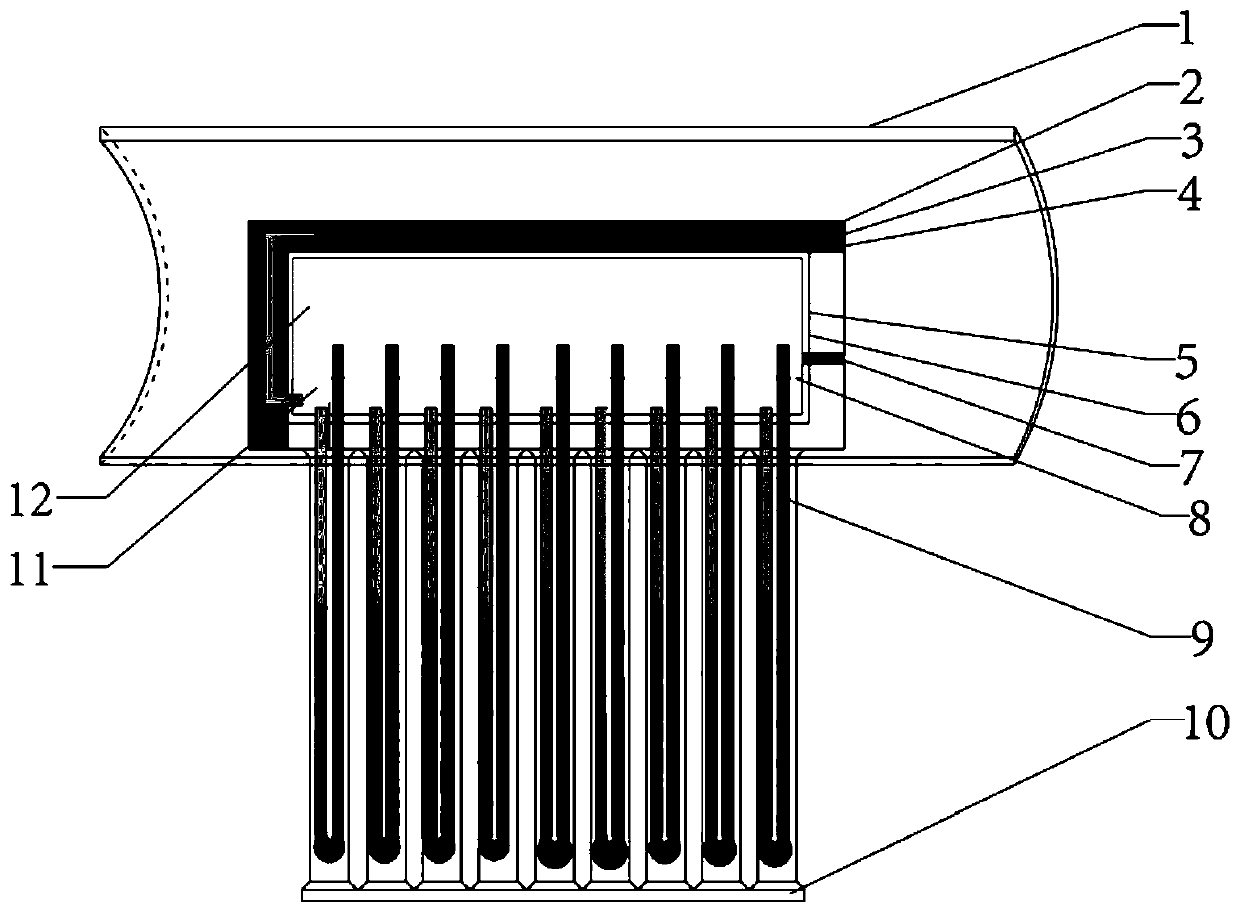

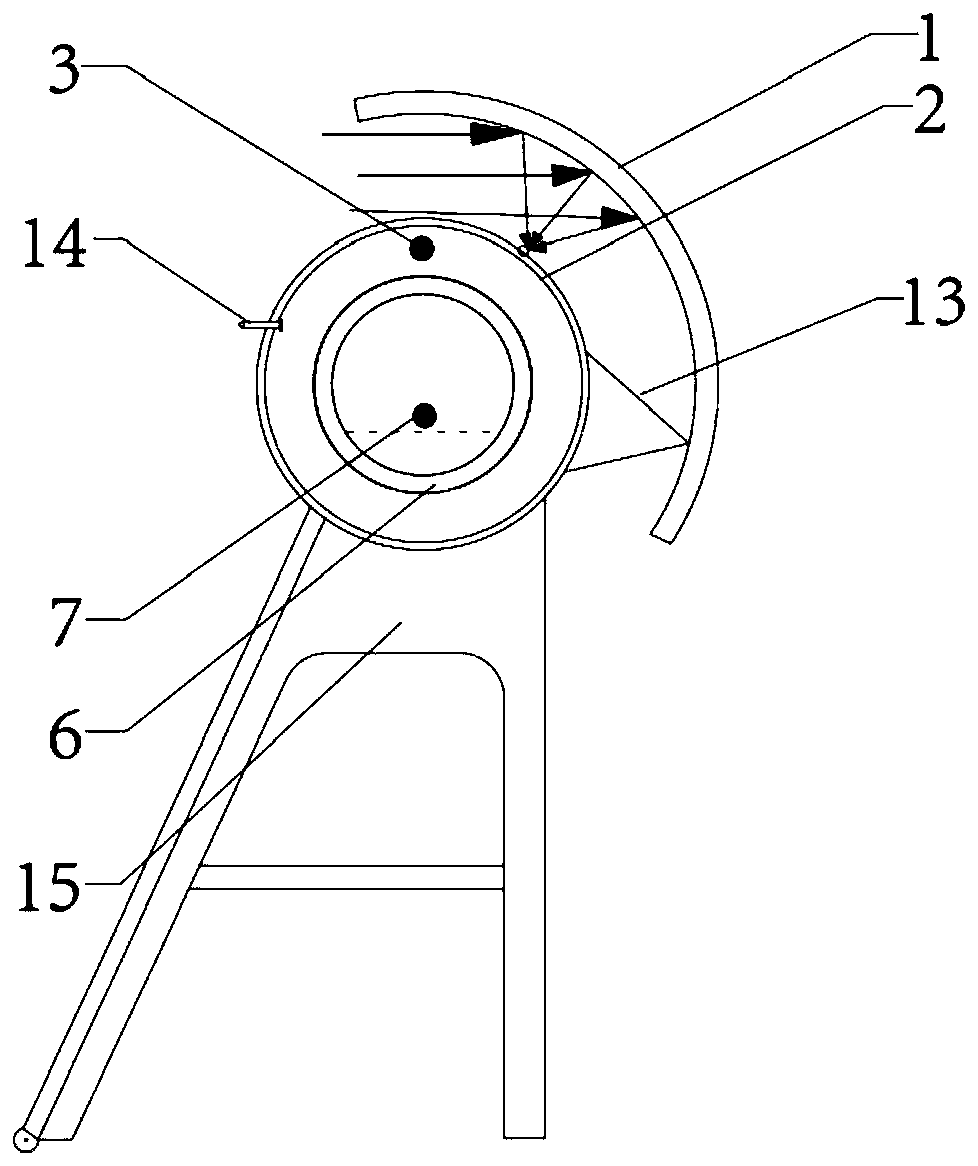

[0023] A vacuum tube explosion-proof synergistic water heater with phase change temperature control, such as figure 1 As shown, its structure includes concentrating plate 1, phase change heat storage shell 2, cold water preheating pipe 3, stepped phase change material 4, heat preservation water tank 5, heat insulation layer 6, hot water outlet 7, cold and hot partition 8, vacuum Glass tube 9, header 10, preheated water collection box 11, hot water collection box 12, support 15. The concentrating plate 1 is fixedly connected to the phase change heat storage shell 2 through the rib 13, and the phase change heat storage shell 2 is filled with a step phase change material 4, and the cold water preheating pipe 3 passes through the step phase change material 4 to the heat preservation water tank 5 . After tap water enters the cold water preheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com