Cooling components and electronic equipment

A technology for heat-dissipating components and electronic equipment, which is applied in the structural parts of electrical equipment, electrical components, cooling/ventilation/heating renovation, etc. Conducive to heat dissipation, reducing assembly thickness, and reducing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

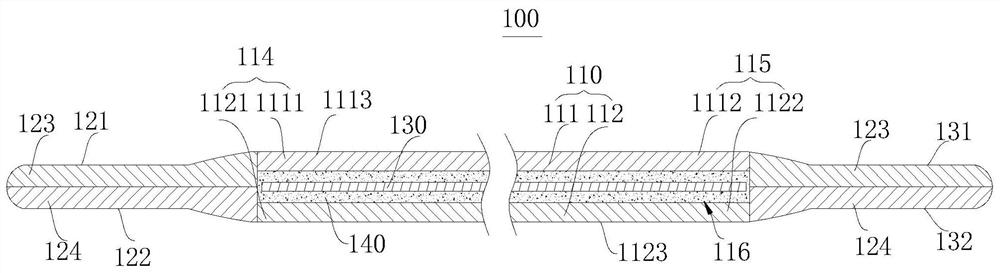

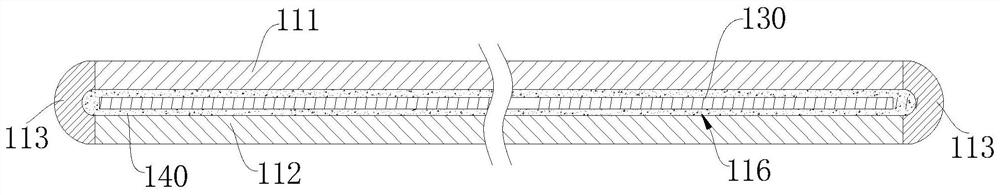

[0021] Please also refer to figure 1 and figure 2 , this embodiment provides a heat dissipation assembly 100, which can be applied to such as Figure 5 or Figure 7 As shown in the electronic device 200, the heat dissipation assembly 100 includes a tube body 110, a first flat connection part 120, a second flat connection part 130, a liquid-absorbing core 130 and a working medium 140, and the first flat connection part 120 and the second flat connection part The part 130 is connected to the tube body 110 , the liquid-absorbing core 130 is arranged in the tube body 110 , and the working medium 140 is filled in the tube body 110 .

[0022] see figure 2 , the tubular body 110 has an opposite first end 114 and a second end 115, the first flat connecting portion 120 is connected to the first end 114, the second flat connecting portion 130 is connected to the second end 115, the tubular body 110 1. The first flat connection part 120 and the second flat connection part 130 enclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com