A waste mixing device for waste power generation

A technology of waste power generation and mixing device, which is applied in the directions of mixed material pretreatment, mixer, mixing method, etc., can solve the problems of mixing and stirring, affecting the effect of combustion, large garbage volume, etc., and achieves increased stability, increased effect, The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

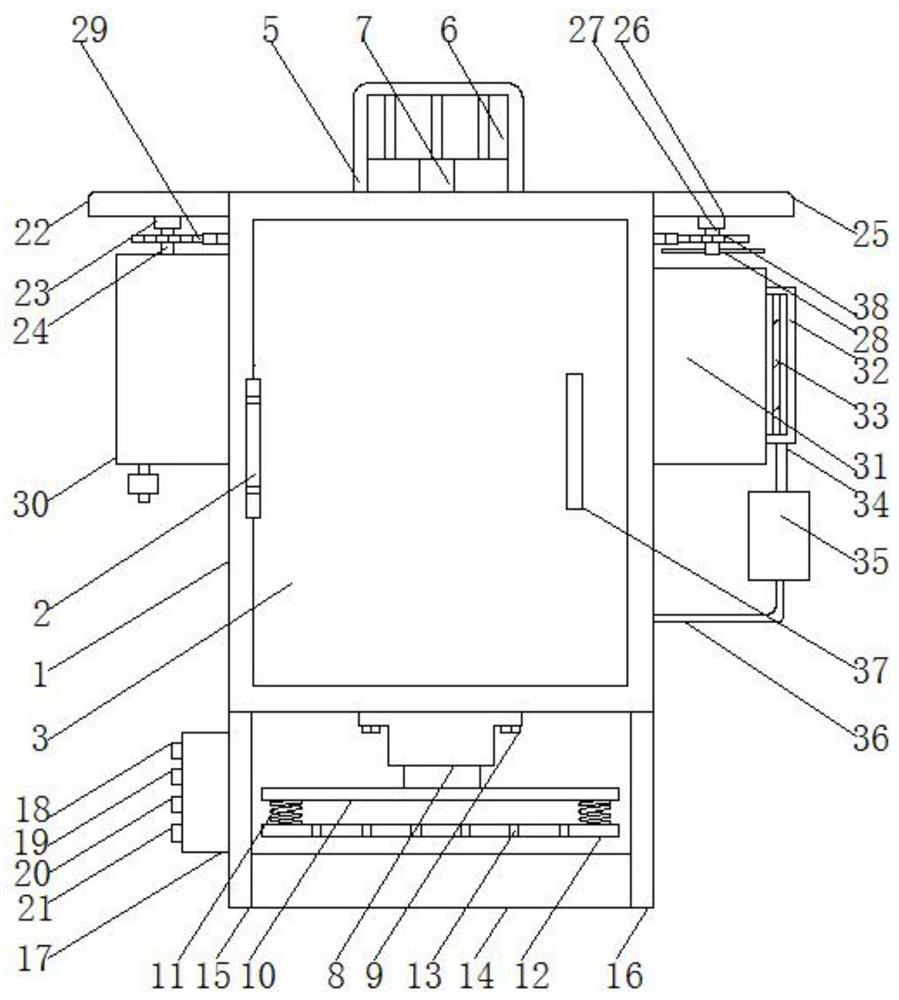

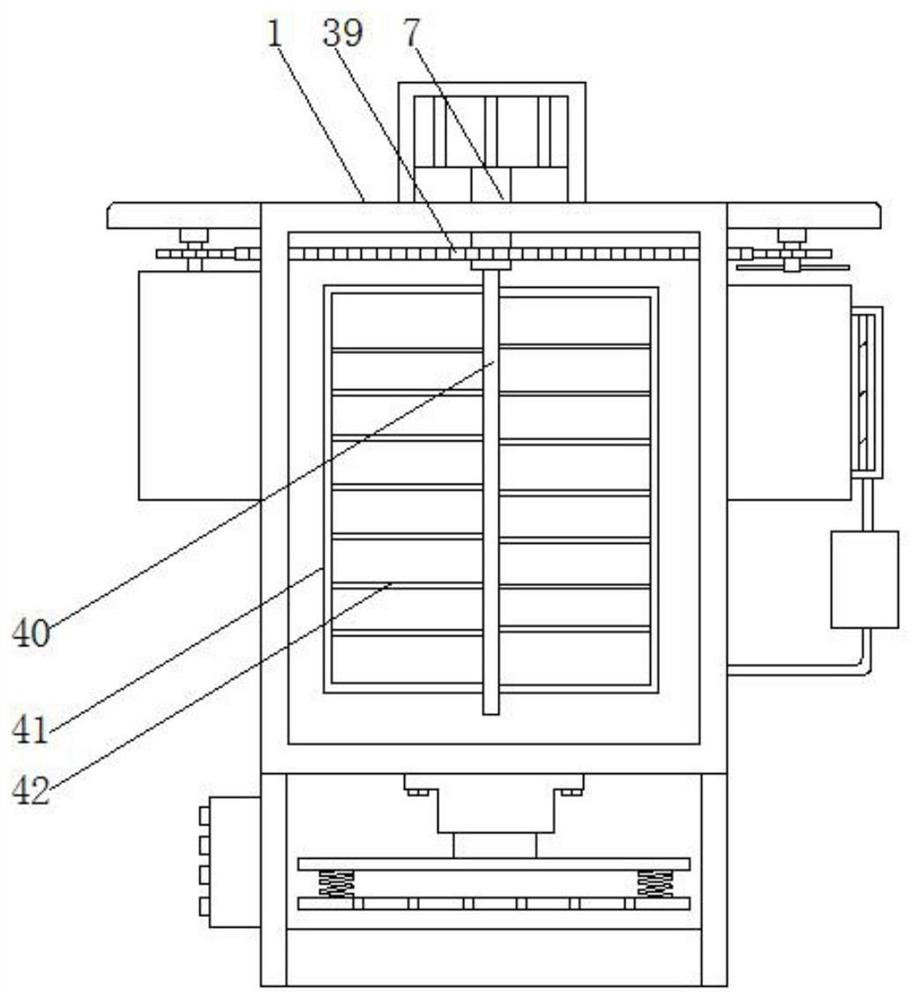

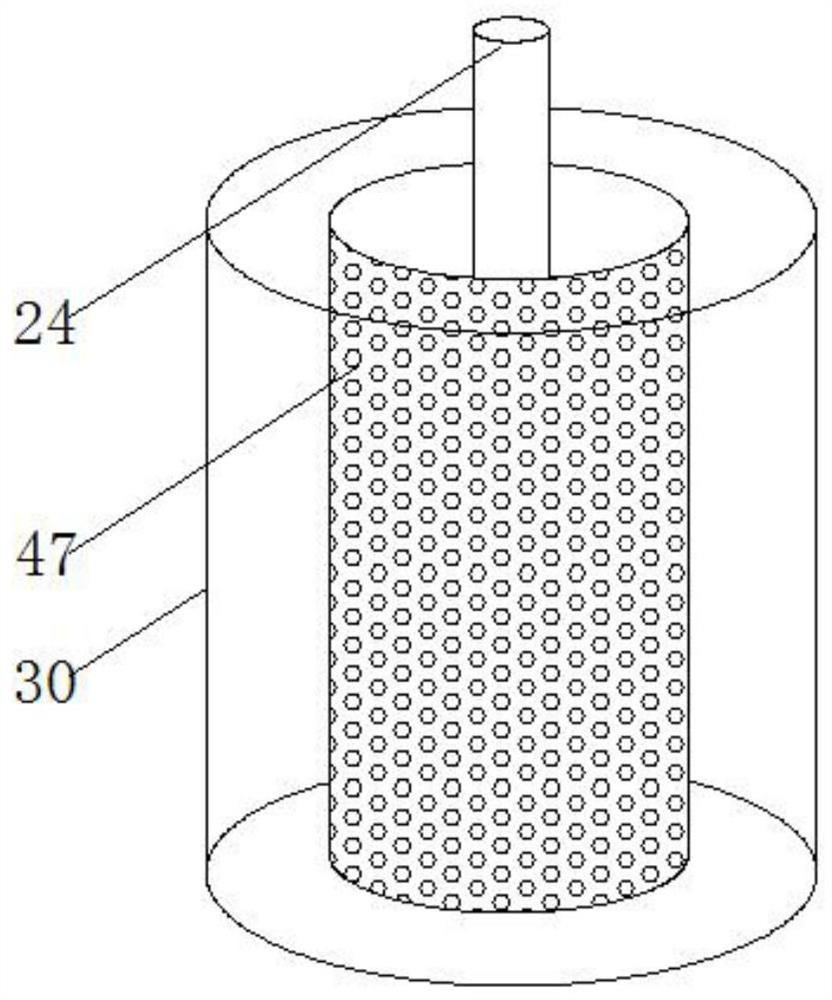

[0027] See Figure 1-5The present invention provides a technical solution: a garbage blending device for waste power generation, including a device case 1, and a motor protective cover 5 is mounted in the middle of the device chamber 1, the motor protective cover 5 fixed connection There is a first motor 6, and the first motor 6 is connected to the first motor shaft 7, and the first motor shaft 7 is connected to the mixing rod 40 in the bottom of the device case 1, and the mixing rod 40 is left. The fixed frame 41 is welded, and the fixed frame 41 is fixedly connected to the mixed blade 42, and the mixing blade 42 is seven, and the square hole 4 is opened on the top of the upper side of the device casing 1. The first motor shaft 7 is fixedly coupled with a first gear 39, and the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com