Differential bearing mounting device with bilateral bearing self-centering function and mounting method thereof

A technology of installation device and differential gear, which is applied in the direction of assembly machine, metal processing, metal processing equipment, etc., can solve the problems of difficulty in ensuring assembly accuracy, low efficiency and low efficiency of the screw pair driving clamping mechanism, and achieves good centering. , to avoid effects that are individually controlled and driven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

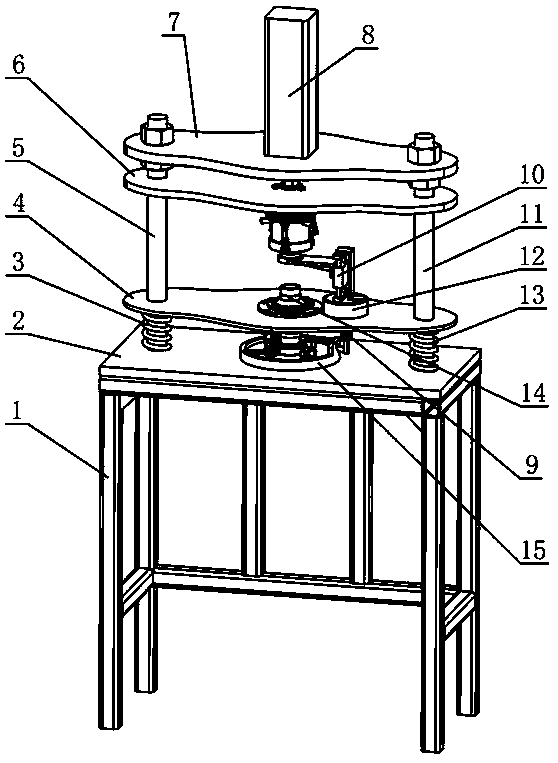

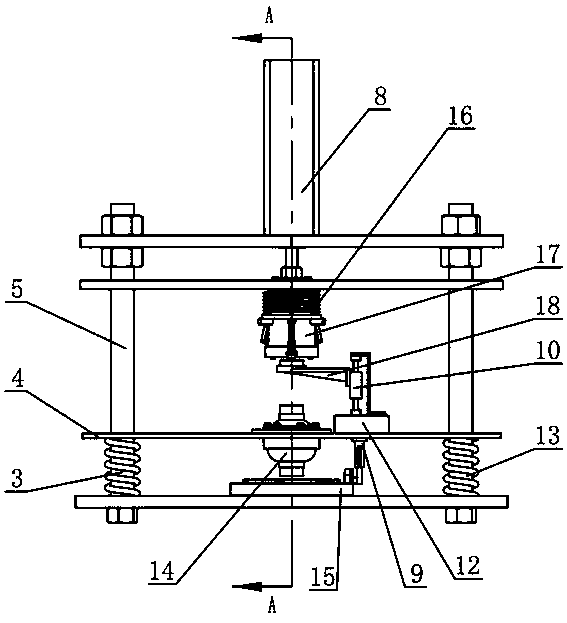

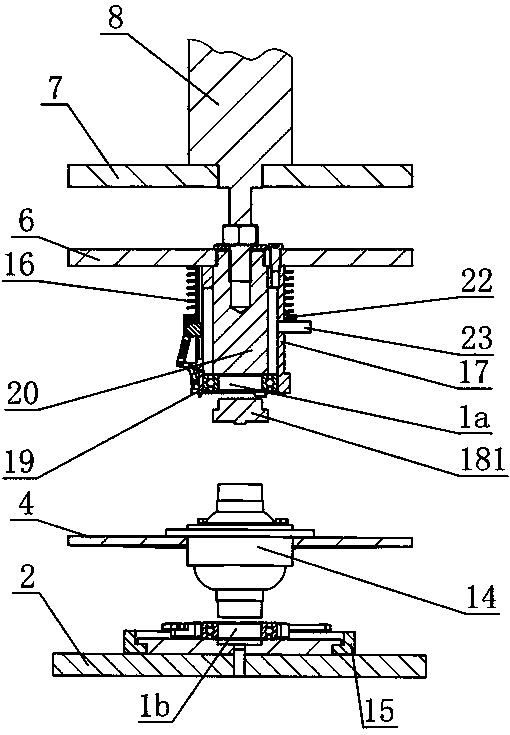

[0060] combine Figure 1-13 , a double-sided bearing self-centering differential bearing installation device of the present invention, including a base frame 1, a bottom plate 2, a left compression spring 3, a differential support plate 4, a left column 5, a pressure plate 6, and a cylinder Fixed plate 7, lifting cylinder 8, lower pressure seat 9, slide table cylinder 10, right column 11, electric turntable 12, right compression spring 13, rotating disc 15, clamping spring 16, bearing fixing seat 17, bearing bracket 18, Clamping block 19, mandrel 20, synchronous ring 22, stop pin 23, connecting rod 1 24, connecting rod 2 25, slider 26, hinge shaft 27, guide block 28, driving rod 29, fixed disc 30, pressing block 31, column pin one 32, column pin two 33, column pin three 34, press down bar 35, press down spring 36, control system, with attached figure 2 The orientation defines the up-down and left-right directions of the application, and the direction in which the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com