Continuous glass fiber composite reinforced pipe winding machine and using method thereof

A technology of composite reinforcement and continuous glass fiber, which is applied in the field of glass fiber composite reinforced pipe winding equipment, can solve the problems of large deviation of pipe concentricity, large number of glass fiber tape reels, and high manufacturing cost of equipment, so as to save floor space and space , Low manufacturing cost, and the effect of reducing the number of ring belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

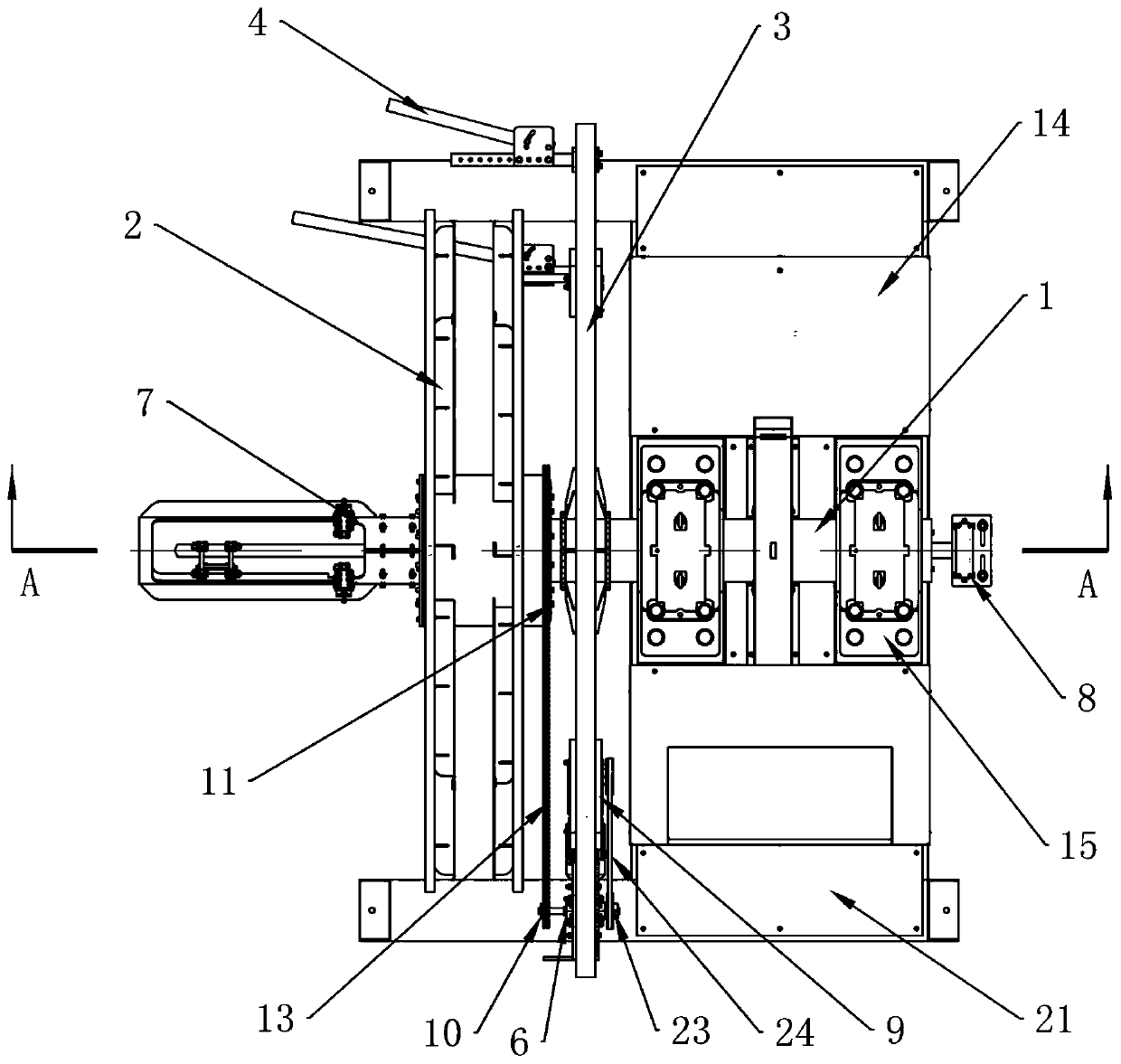

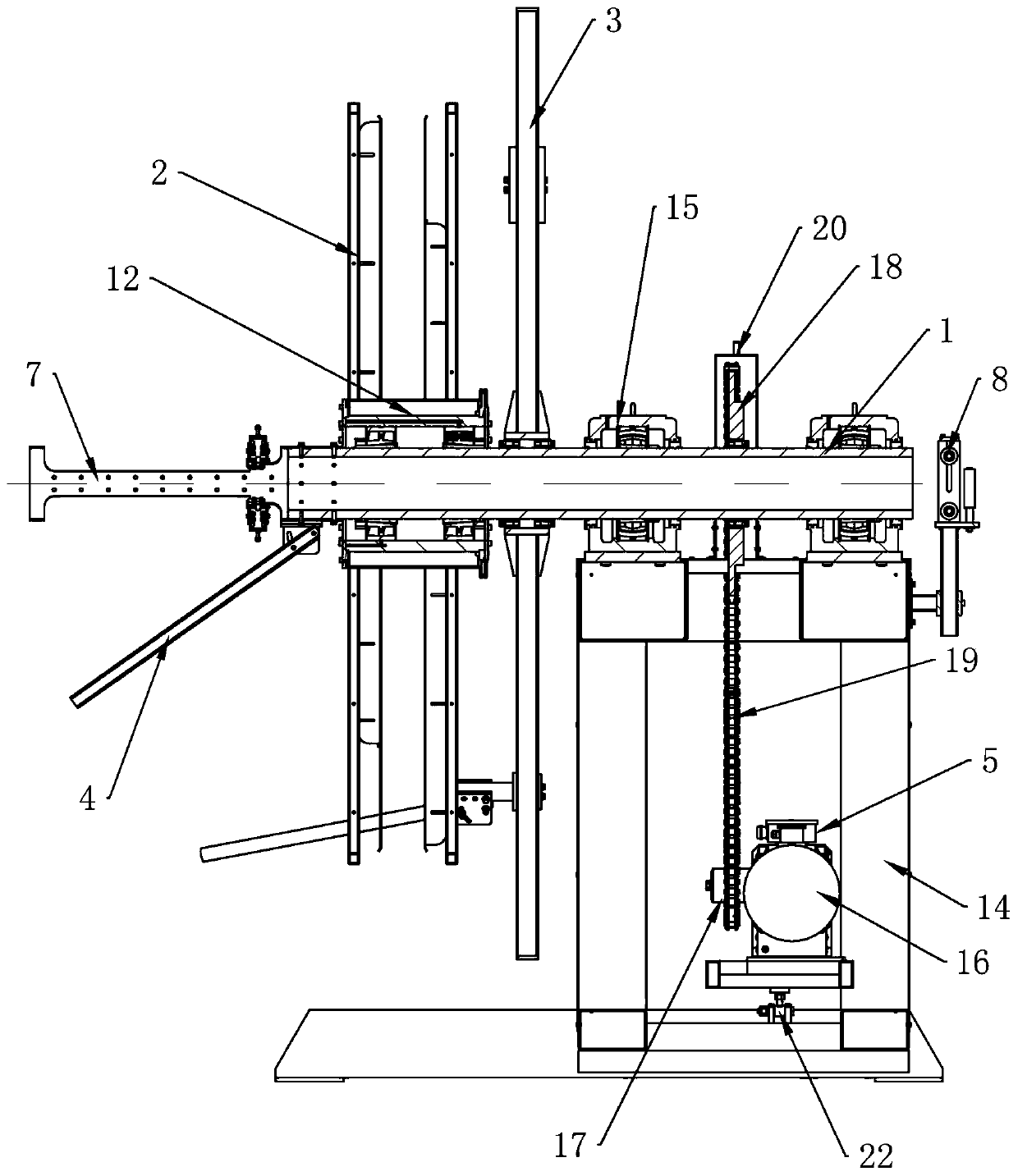

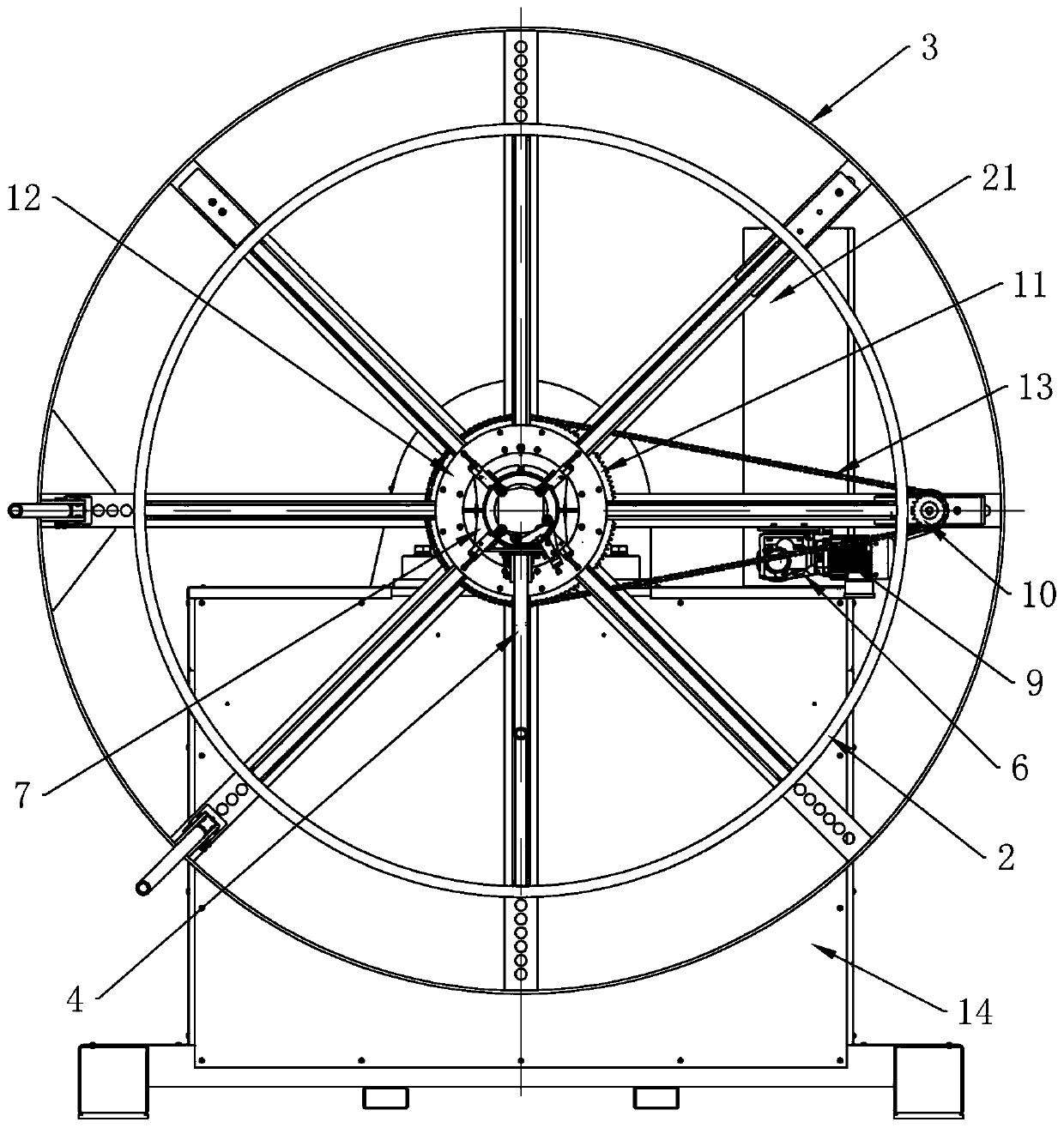

[0062] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, the second transmission group 6 includes: a first motor 9, a V pulley 23, a first sprocket 10 and a second sprocket 11, the first motor 9 is arranged on the winding disc 3, and the first motor 9 passes through the belt 24 The first sprocket 10 is connected to the V-pulley 23 in transmission, the glass fiber disk 2 is connected to the winding main shaft 1 through the expansion mechanism 12, and the second sprocket 11 is located on the expansion mechanism 12 close to the winding On one end of the disk 3 , the first sprocket 10 is in driving connection with the second sprocket 11 through a first roller chain 13 . Preferably, the expansion mechanism 12 is an annular expansion shaft.

[0063] In a further embodiment of the present invention, the continuous glass fiber composite reinforced pipe winding machine also includes: a servo motor (not shown in the figure), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com