Rotary copper bar double-head electroplating device

An electroplating device and rotary technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of lower production efficiency, re-disassembly, labor-intensive, etc., to achieve the effect of reducing disassembly time, convenient adjustment, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

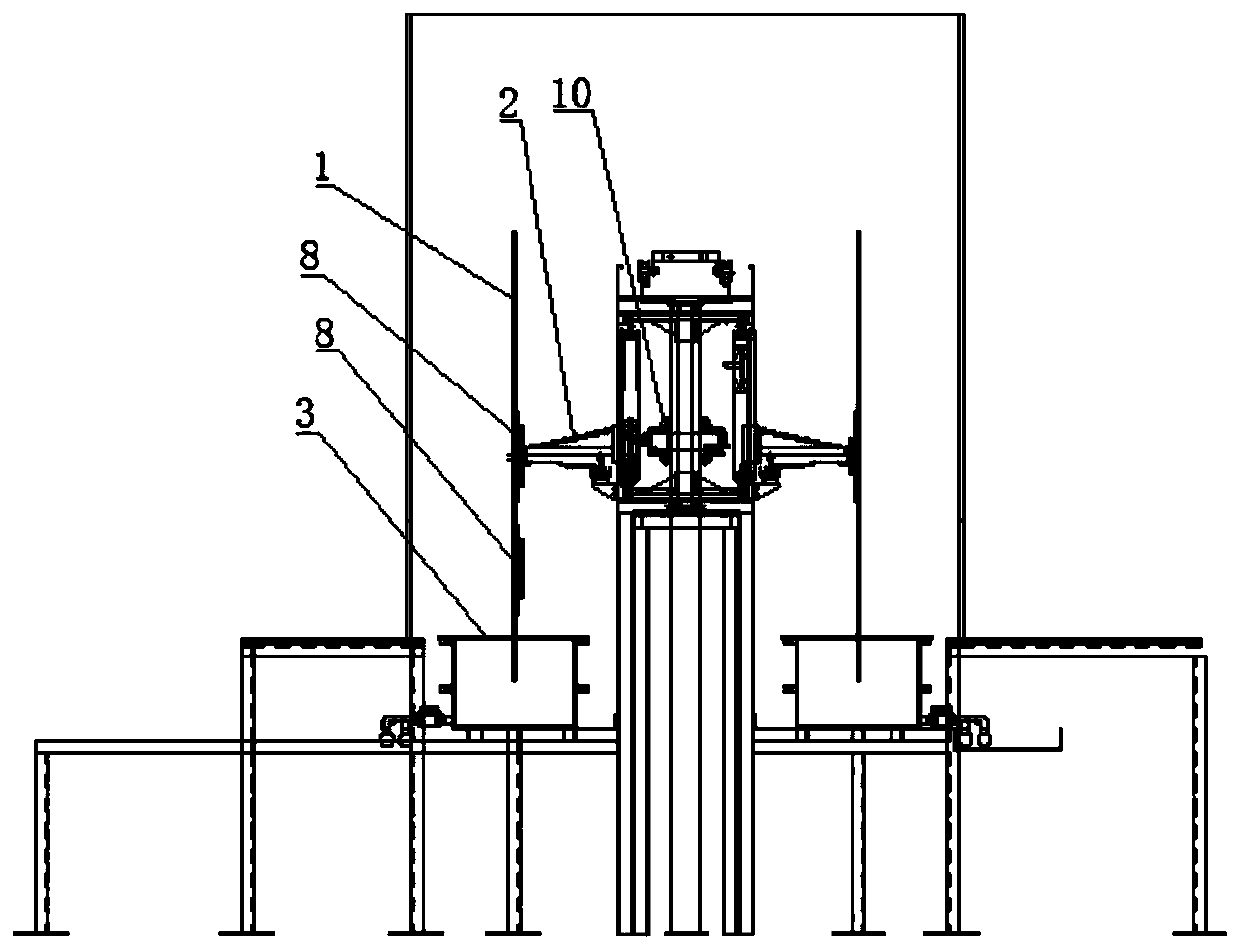

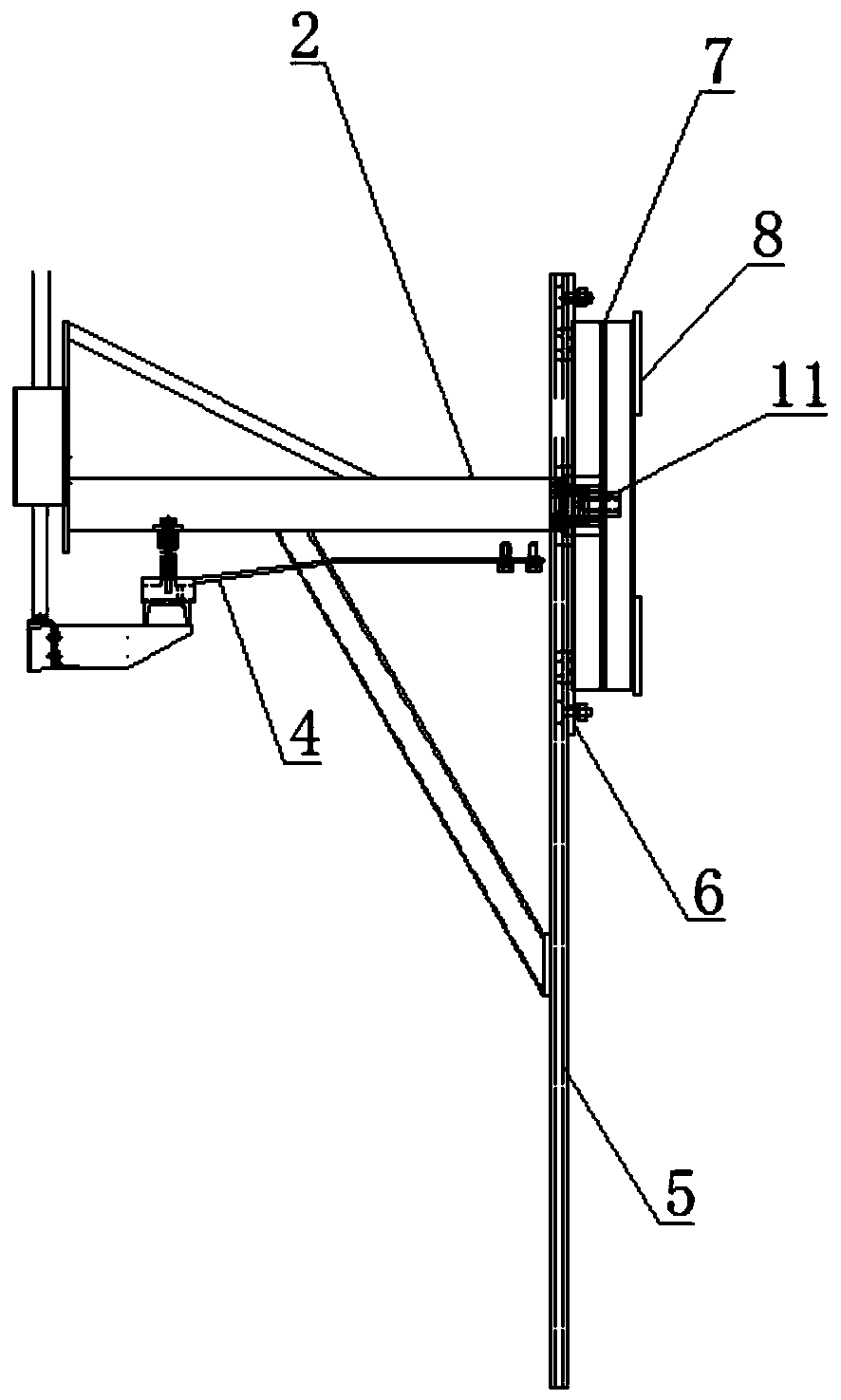

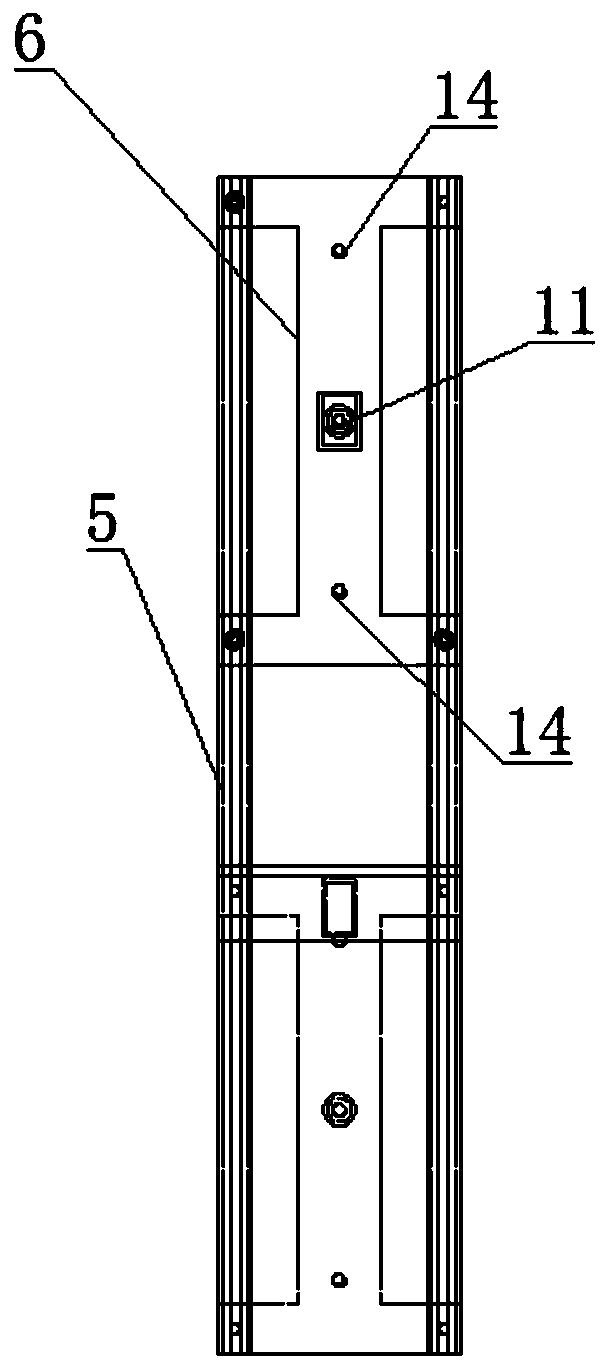

[0030] like Figure 1-4 Shown: a rotary double-head electroplating device for copper bars, including a lifting mechanism 10, an arm frame 2, a fixed guide rail 5, a chassis plate 6, a telescopic guide rail 7, a quick clamp pressing plate 8, a quick clamp 9, and a bearing assembly 11,

[0031] Described lifting mechanism 10 comprises motor, guide rail, gear and chain, and described gear is arranged on the top of described guide rail, and described chain passes through described gear, and the other end of described chain is connected with described arm frame 2 ends, thus The arm frame 2 can be lifted and lowered freely on the guide rail,

[0032] The arm frame 2 includes a brace and a cantilever, the end of the arm frame 2 is installed on the lifting mechanism 10, the front end of the arm frame 2 is fixedly connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap