Integrated prefabricated wall panel building structure

A technology of prefabricated wall panels and houses, which is applied in the direction of building structure and construction, can solve the problems of complicated construction steps, achieve the effect of consistent and beautiful appearance, reinforced connection fastness, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

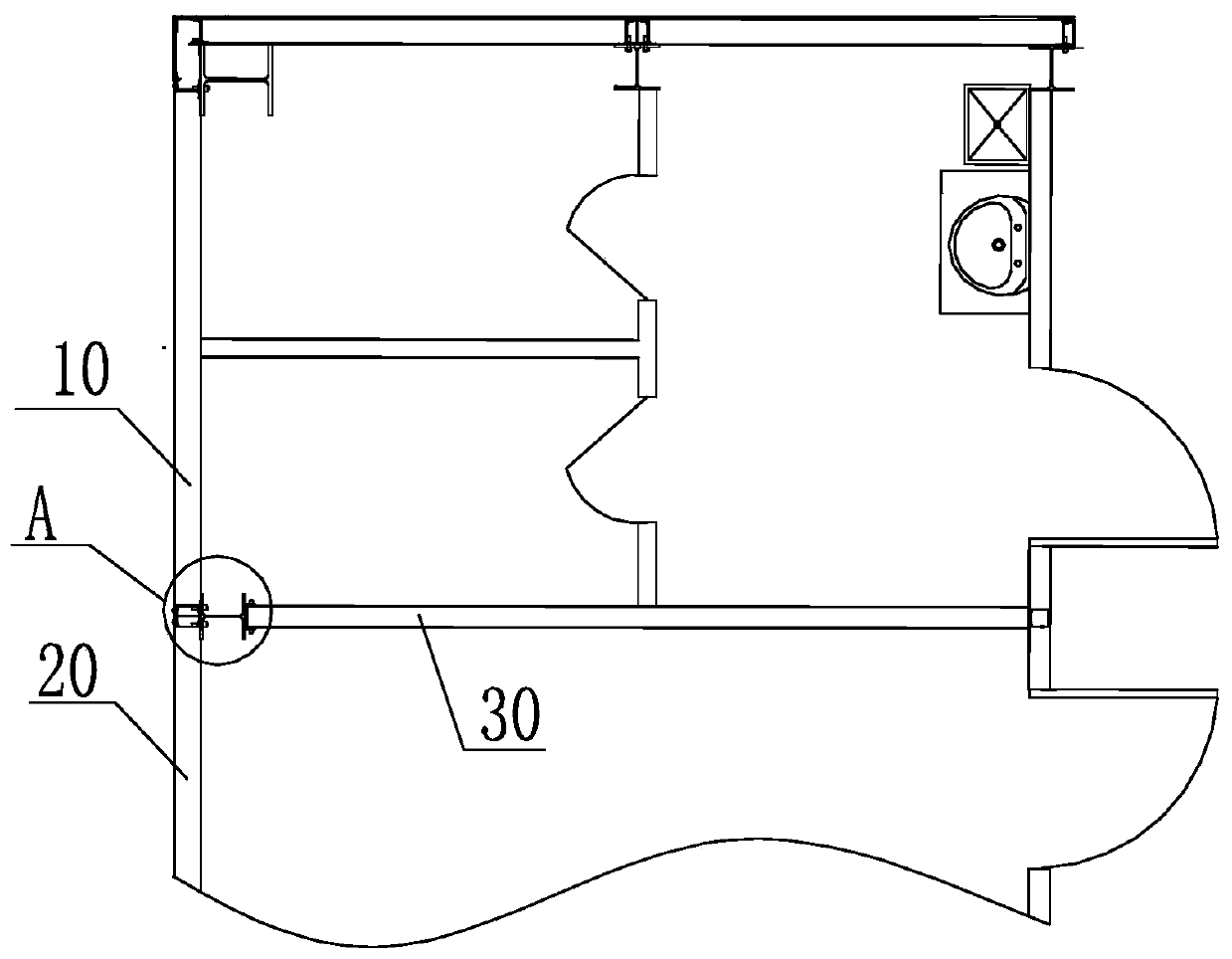

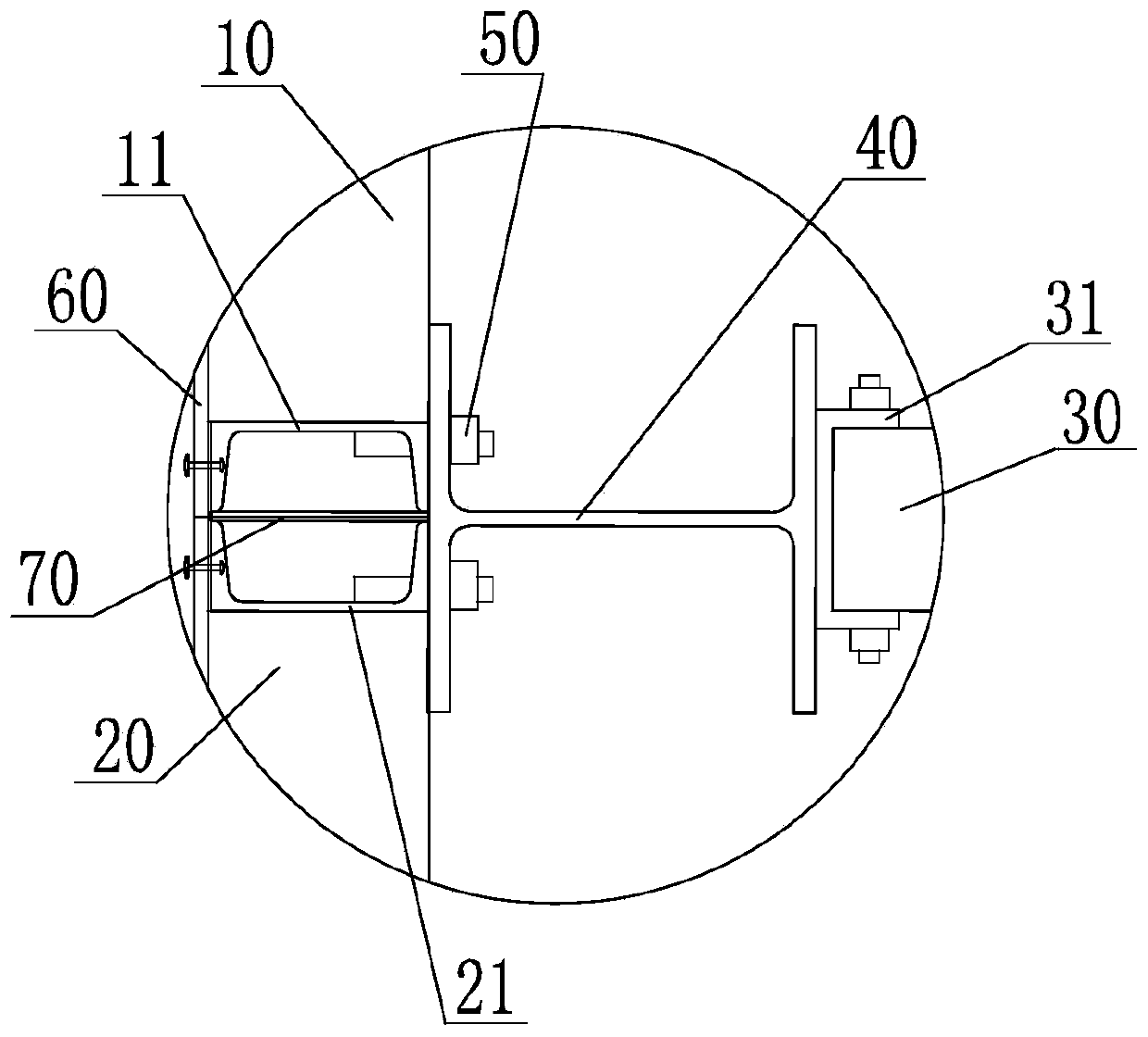

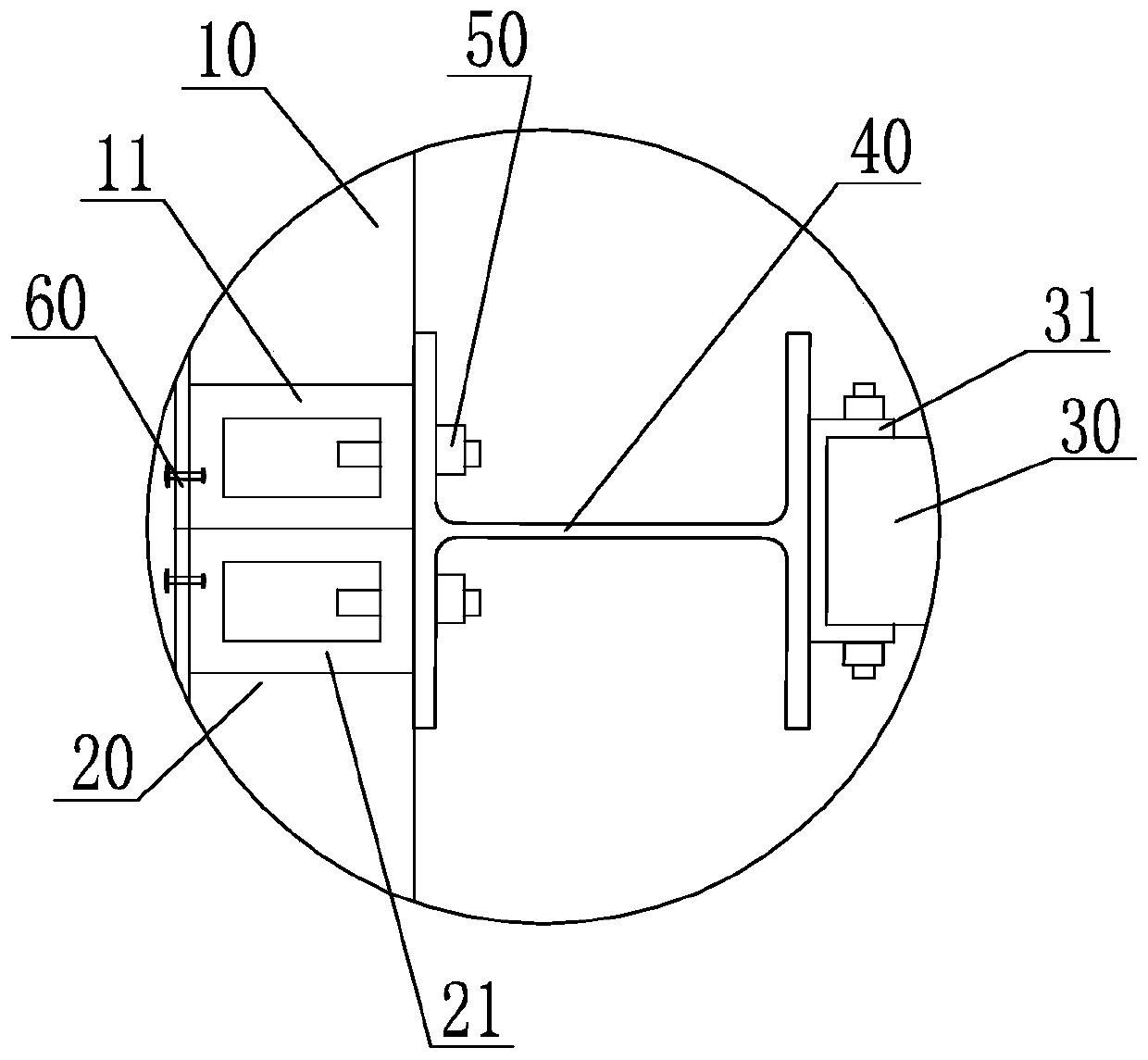

[0036] like Figure 1-3 As shown, the integrated prefabricated wall panel house structure is bolted to the third connecting part 40 by prefabricating the connecting piece on the integrated prefabricated wall panel, and the fourth connecting part 31 is connected between the inner wall panel and the third connecting part 40 connect.

[0037] The integrated prefabricated wall panel includes a first wall panel 10 and a second wall panel 20, and the prefabricated connector includes a first connecting part 11, a second connecting part 21 and bolts 50, and the first wall panel 10 and the second wall panel 20 are in the same On a plane and arranged adjacent to each other, the house structure also includes an inner wall panel 30, the first connecting part 11 and the second connecting part are respectively fixedly arranged on the adjacent surfaces of the first wall panel 10 and the second wall panel 20 21. A fourth connection part 31 is fixedly arranged on the inner wall panel 30, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com