Gas-gas mixed flame stabilization device

The technology of a flame stabilizing device and a mixer is applied in combustion methods, lighting and heating equipment, continuous combustion chambers, etc., and can solve problems such as difficulty in efficient and uniform mixing, and limited penetration ability of fuel-rich gas, so as to improve penetration ability, Reduce the difficulty of heat protection and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

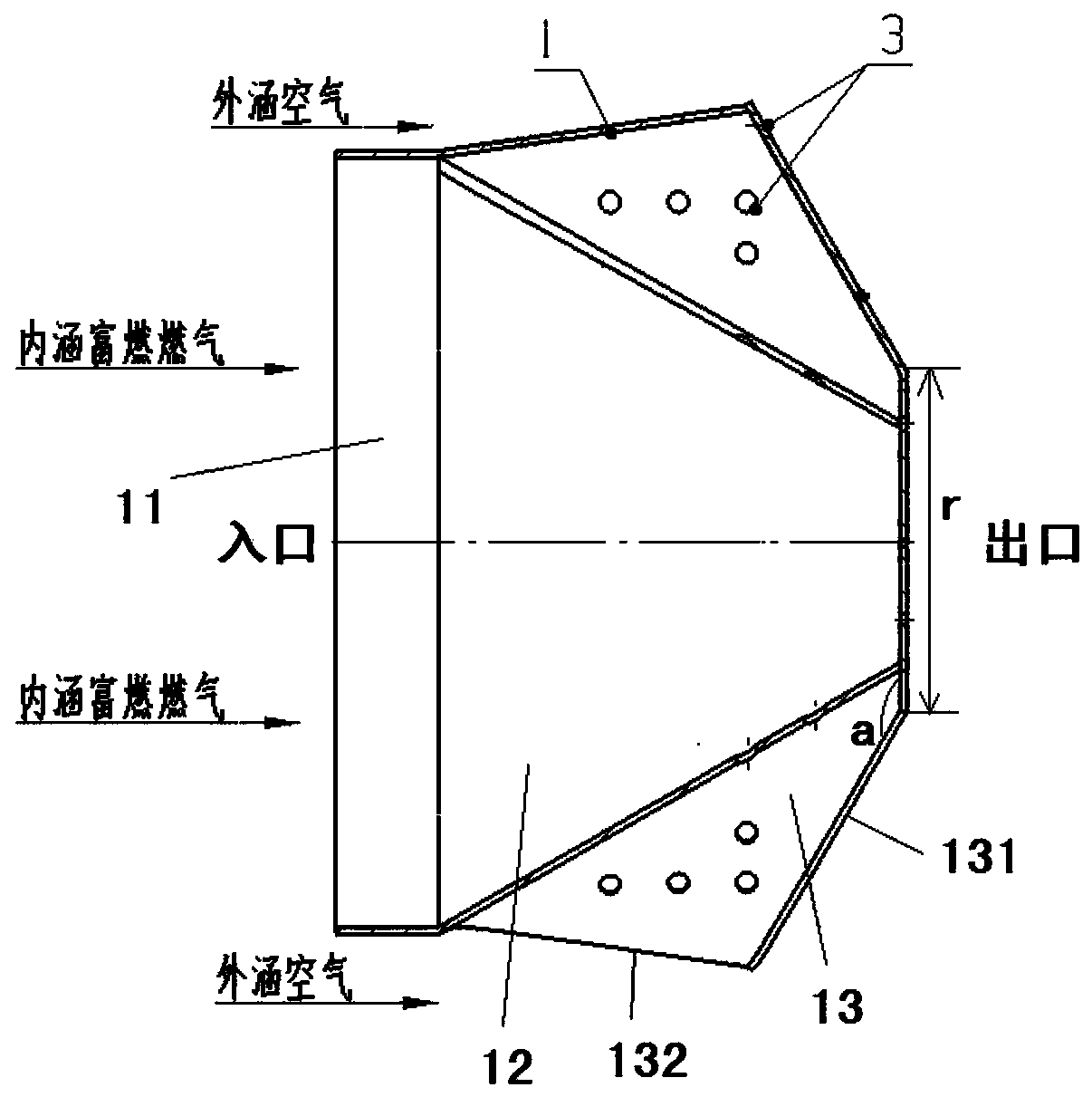

[0025] The invention provides a gas-gas mixing flame stabilizing device, which realizes the gas-gas mixing and flame stabilizing device before entering the combustion chamber. The structure is simple and reliable, and the weight is light. In the case of a total pressure recovery coefficient ≮0.80), the efficient mixed combustion of internal rich fuel gas and external air is realized, which meets the working requirements of the engine within the range of Ma0-3.5.

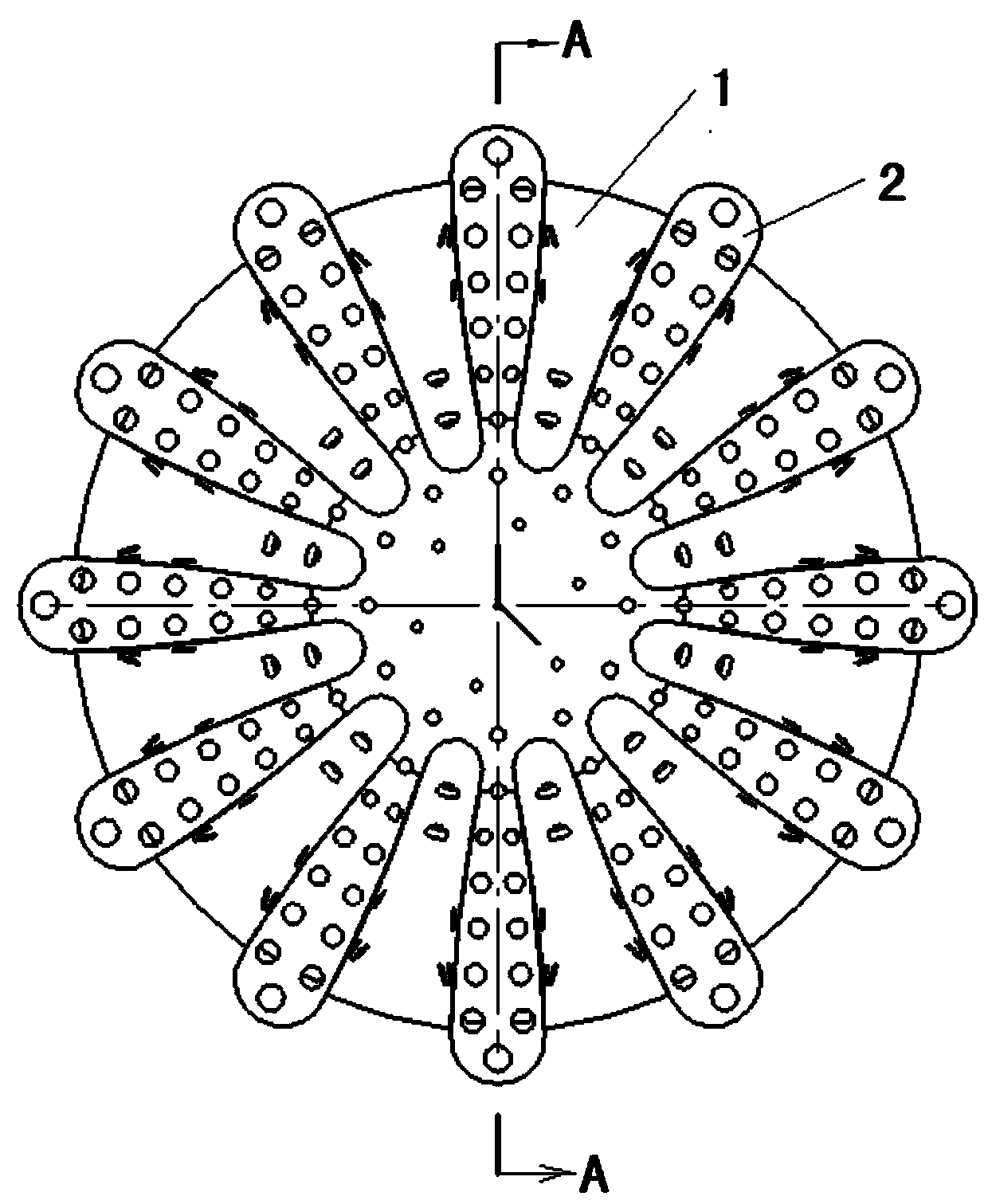

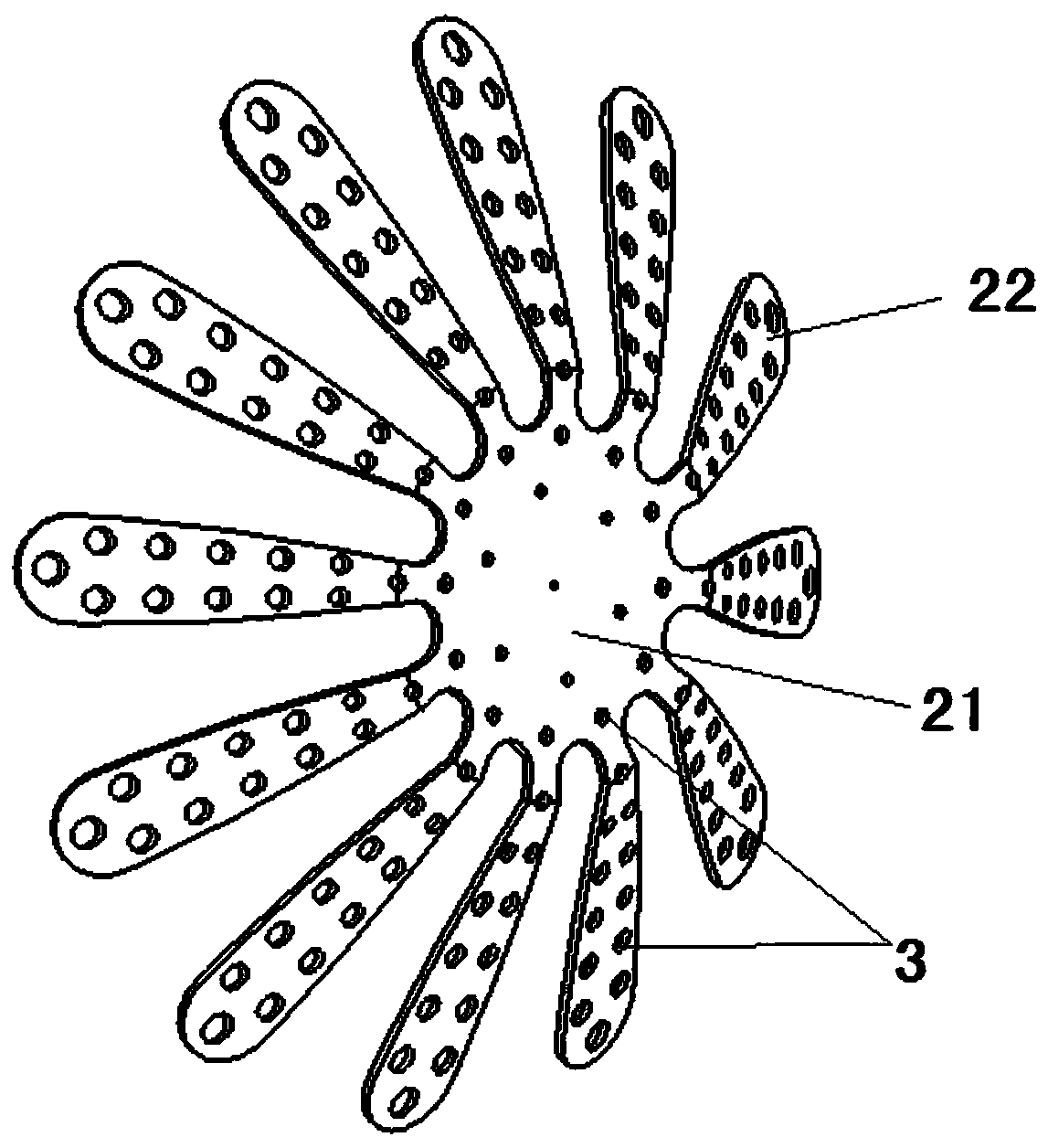

[0026] Such as figure 1 Shown is a schematic diagram of the shaft end of the gas-gas mixing flame stabilizing device. It can be seen from the figure that the gas-gas mixing flame stabilizing device includes an obliquely cut lobe mixer 1 and a cover plate 2; wherein, the obliquely cut lobe mixer 1 It is a hollow cone-column structure with openings at both ends in the axial direction; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com