Flexible cable process digital prototype construction system and method for spacecraft assembly

A spacecraft assembly and flexible cable technology, applied in the direction of electrical digital data processing, instruments, computer-aided design, etc., can solve problems such as unavoidable, complicated branch relationship of cable components, and narrow space for spacecraft assembly, so as to reduce the occurrence of quality problems The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

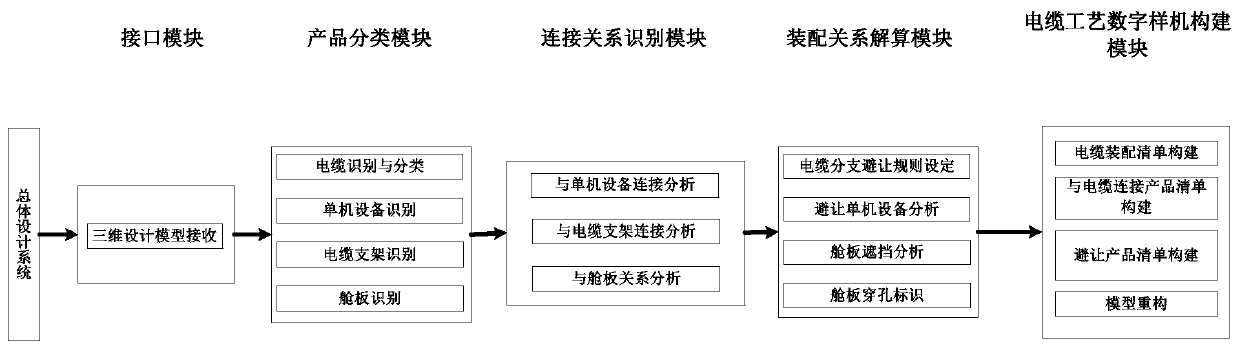

[0036] see figure 1 , figure 1 It shows a schematic diagram of the module structure of the digital prototype automatic construction system for the spacecraft general assembly flexible cable process of the present invention. Among them, the module structure of the automatic construction system of digital prototype of flexible cable technology for spacecraft assembly mainly includes the following modules: interface module, product classification module, connection relationship identification module, assembly relationship calculation module, and cable technology digital pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com