Sustainable sound production electromagnetic buzzer with heat dissipating function

An electromagnetic and buzzer technology, applied in the direction of sounding equipment, instruments, etc., can solve problems such as heat generation and component damage, and achieve the effect of avoiding burnout and reducing working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

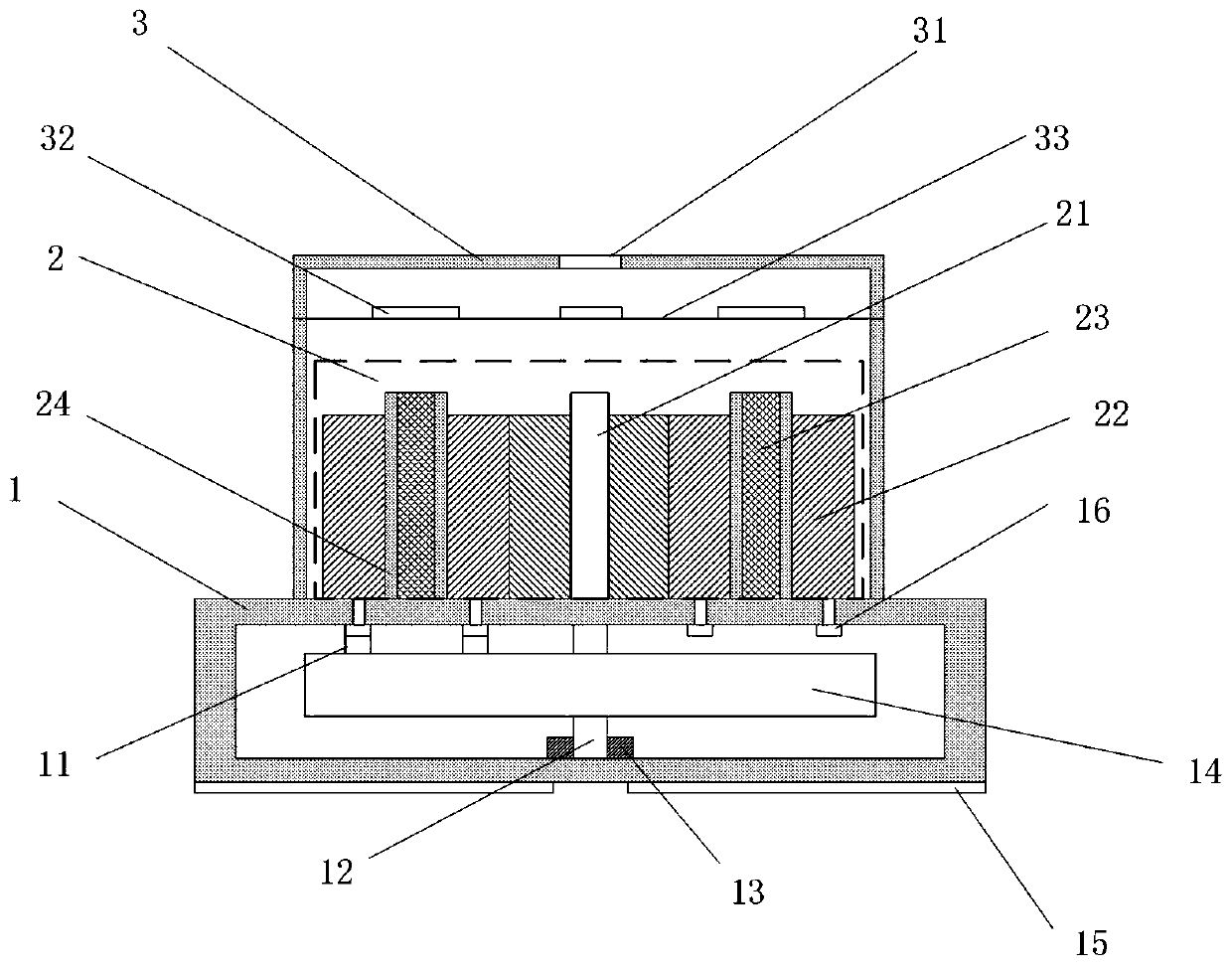

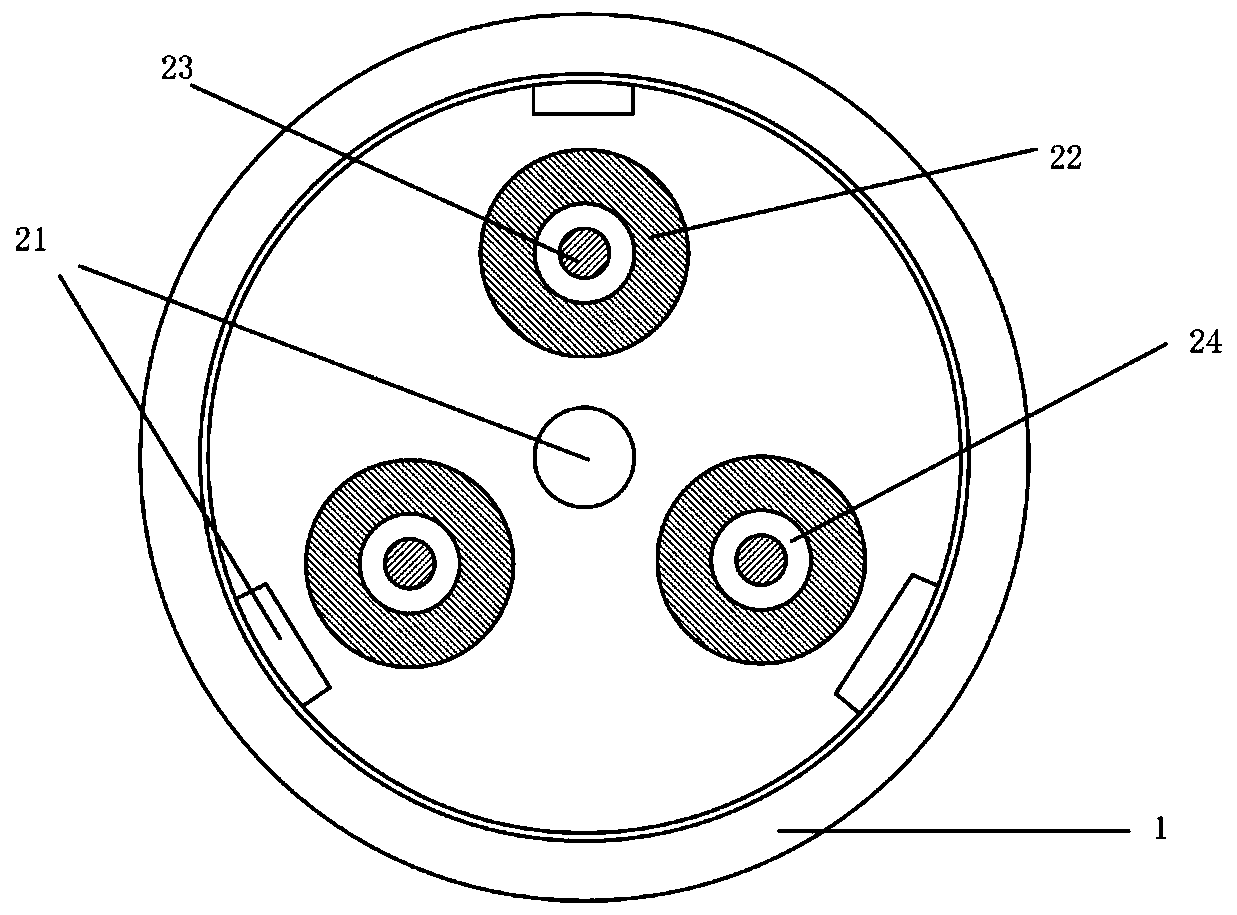

[0021] Such as figure 1 and figure 2 As shown, the present invention includes a base 1, an electromagnetic drive device 2 and an upper cover 3. The top of the base 1 is provided with an electromagnetic drive device 2 and an upper cover 3. The upper cover 3 is covered on the outside of the electromagnetic drive device 2. The upper cover 3 adopts heat dissipation performance Good adhesive bond to base 1. The base 1 is a hollow cylindrical structure, and the bottom of the inner chamber of the base 1 is equipped with a rotating drive device. The rotary driving device includes a rotary motor 13, which is installed at the central position of the inner bottom of the base 1, and the center of the rotary motor 13 is covered with a rotating shaft 12, and the top of the rotating shaft 12 is fixed to the top of the inner cavity of the base 1. The rod 14 and the rotating motor 13 ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap