Compression-resistant composite cable

A composite cable and cable technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cable internal core wire damage, communication power system damage, economic loss, etc., and achieve increased use safety, efficient heat dissipation, and rapid and efficient heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

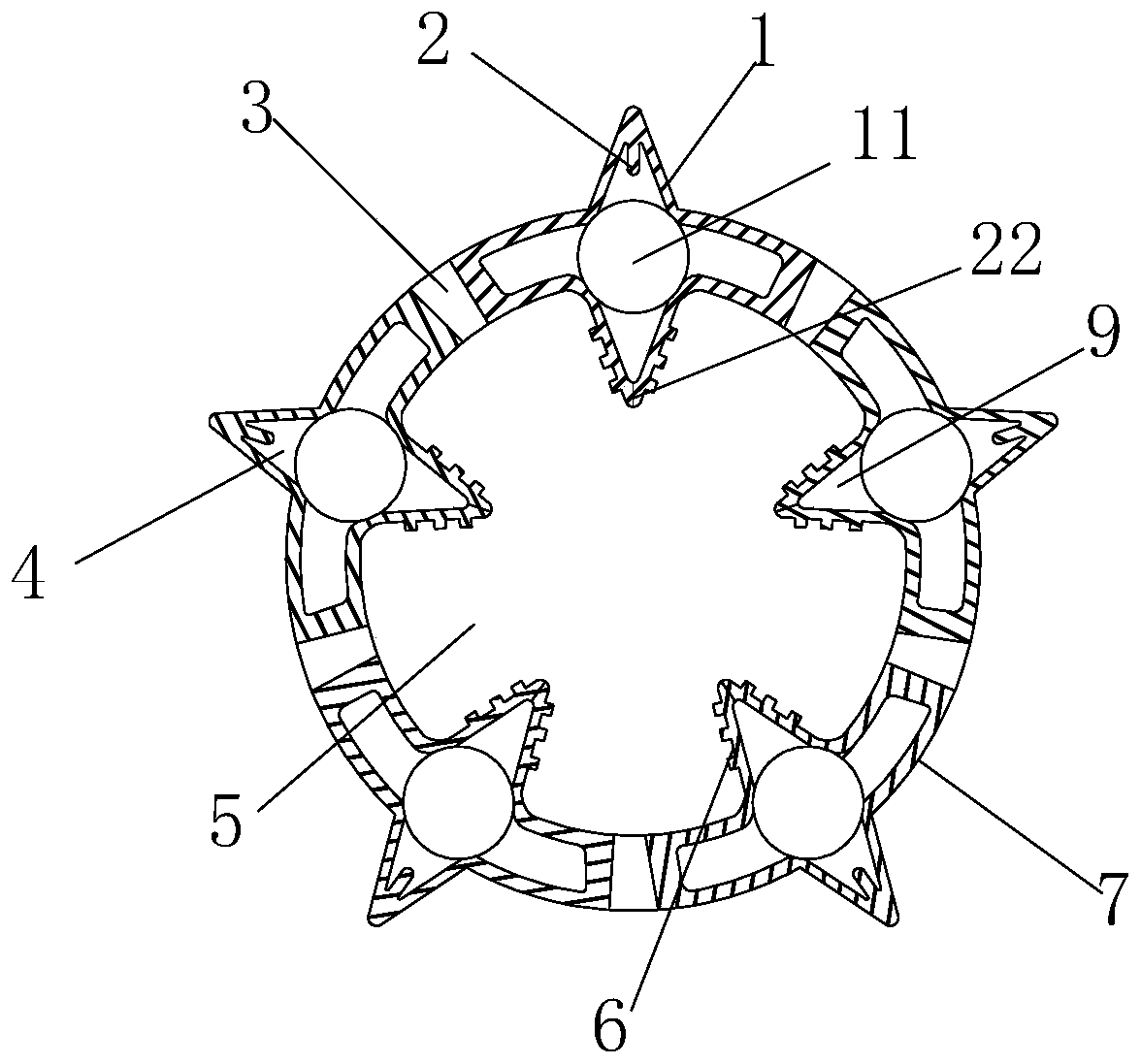

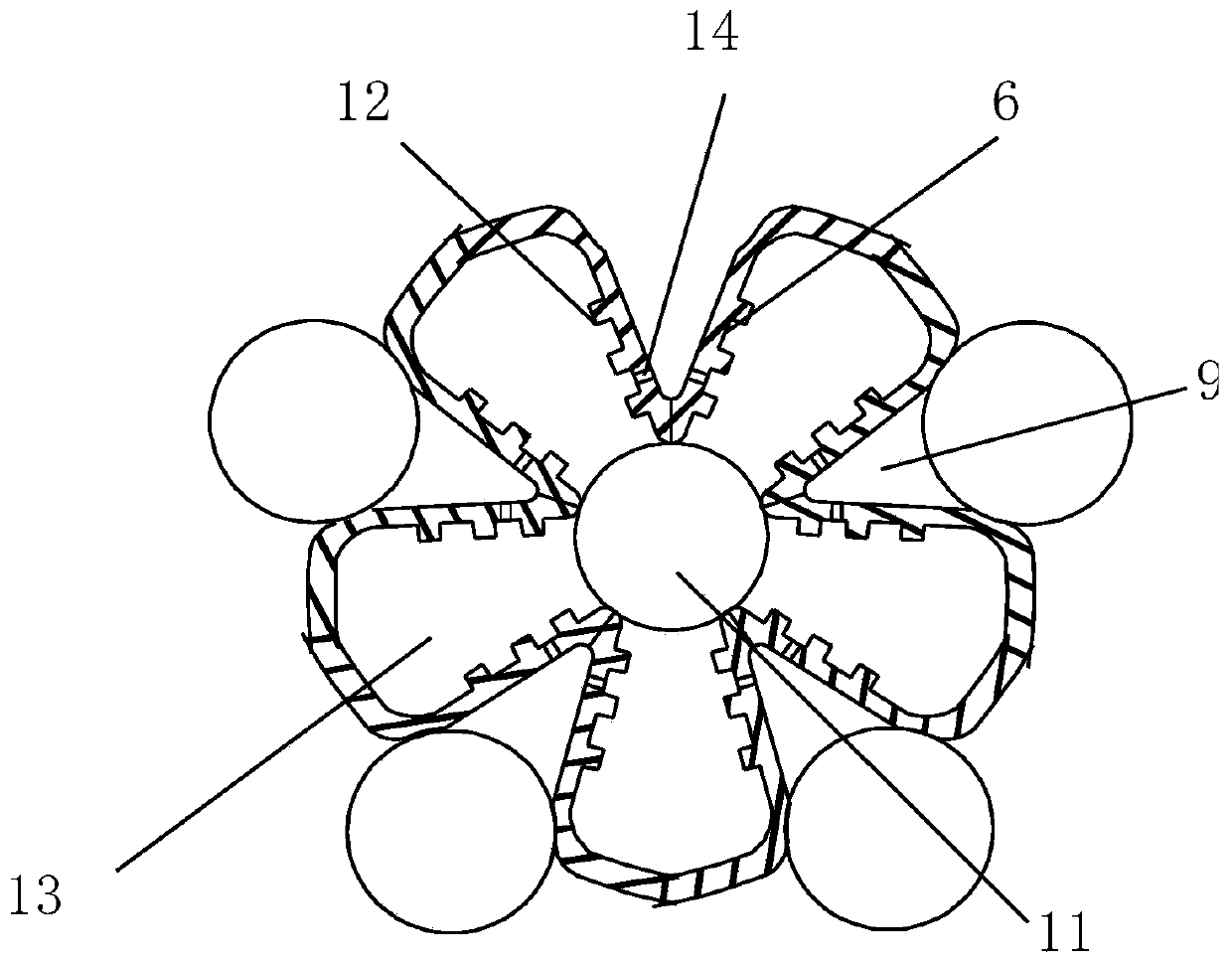

[0016] Such as figure 1 As shown, the compression-resistant composite cable includes a cable outer layer 7, and the outer surface of the cable outer layer 7 is surrounded by a circle of the cable outer layer. There are more than one protruding first protrusions 1, and the cable outer layer 7 A circular cavity 5 is formed in the center of the cable, and the inner wall of the circular cavity of the outer layer 7 of the cable protrudes around the circular cavity 5 with more than one second protruding portion 6, and each first protruding portion 1 is positive For a second protrusion 6, a first jaw 4 is formed in the middle of the first protrusion 1, and a second jaw 9 is formed in the second protrusion 6 relative to the first jaw 4, and the openings of the two jaws are The ends are arranged opposite to each other and form a closed clamping cavity. A cable core wire 11 is installed in each clamping cavity, and a closed opening 22 is opened on the side of the second protruding part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com