A sealing device for vacuum insulation board

A technology of vacuum insulation board and sealing device, which is applied in the direction of insulation, construction, building components, etc., can solve the problems of inconvenient installation of vacuum board, affecting the insulation effect of insulation board, etc., and achieve the effect of convenient installation and improvement of insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

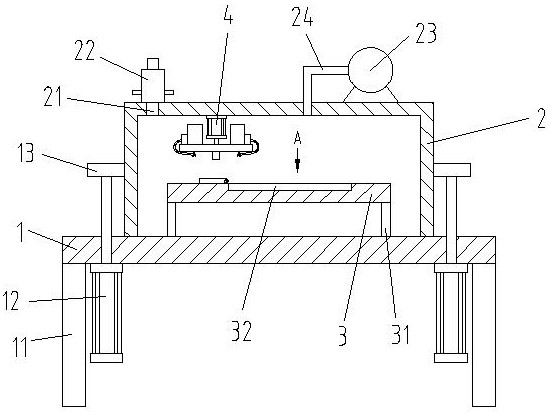

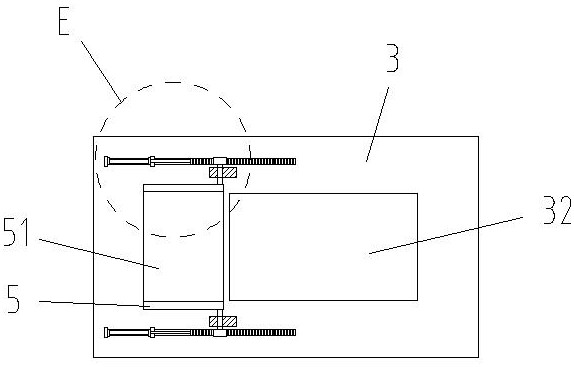

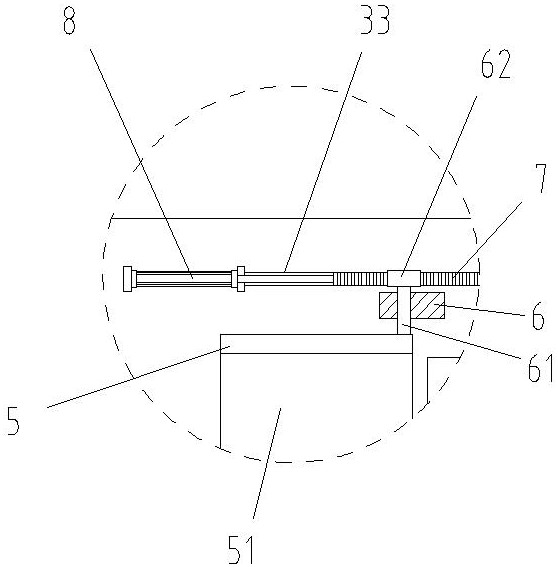

[0020] Such as Figure 1-5 As shown, a sealing device for a vacuum insulation board provided by the present invention includes a base plate 1 supported and fixed by four support columns, and a box body 2 with an opening downward is provided above the base plate 1 . The side is also equipped with a power device for controlling the movement of the box body 2 up and down. The power device includes a cylinder 12, the cylinder 12 is fixedly connected to the bottom of the base plate 1, and the piston rod of the cylinder 12 is arranged vertically upwards. The piston rod of the cylinder 12 penetrates the base plate 1 and extends Out to the top of the base plate 1, the piston rod of the cylinder 12 is fixedly connected to the support plate 13, the support plate 13 is fixedly connected to the box body 2, and the box body 2 can be pushed up or down by the cylinder 12, so that the box body 2 is sealed or exposed. A vacuum pumping device is provided on the top of the casing 2, and the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com