Sunken type 3D printer forming system

A 3D printer and printing material technology, applied in 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of easy damage of LCD screen, slow printing speed, low strength of printed workpiece, etc., and achieve long service life and printing accuracy. High, short exposure time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

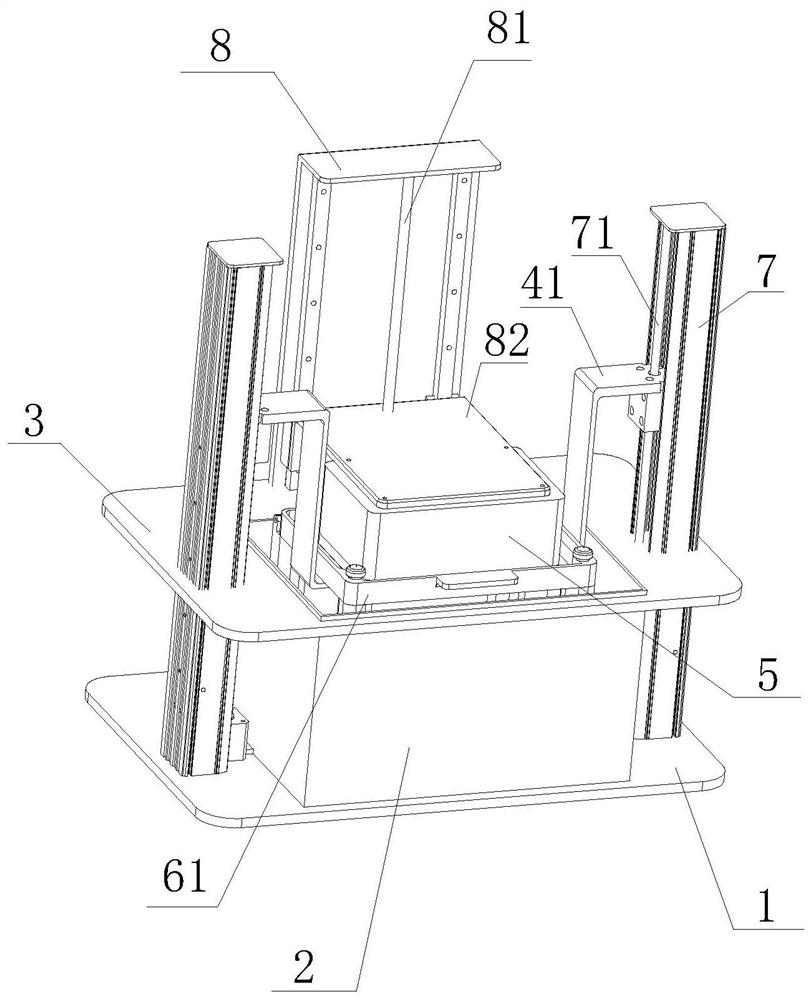

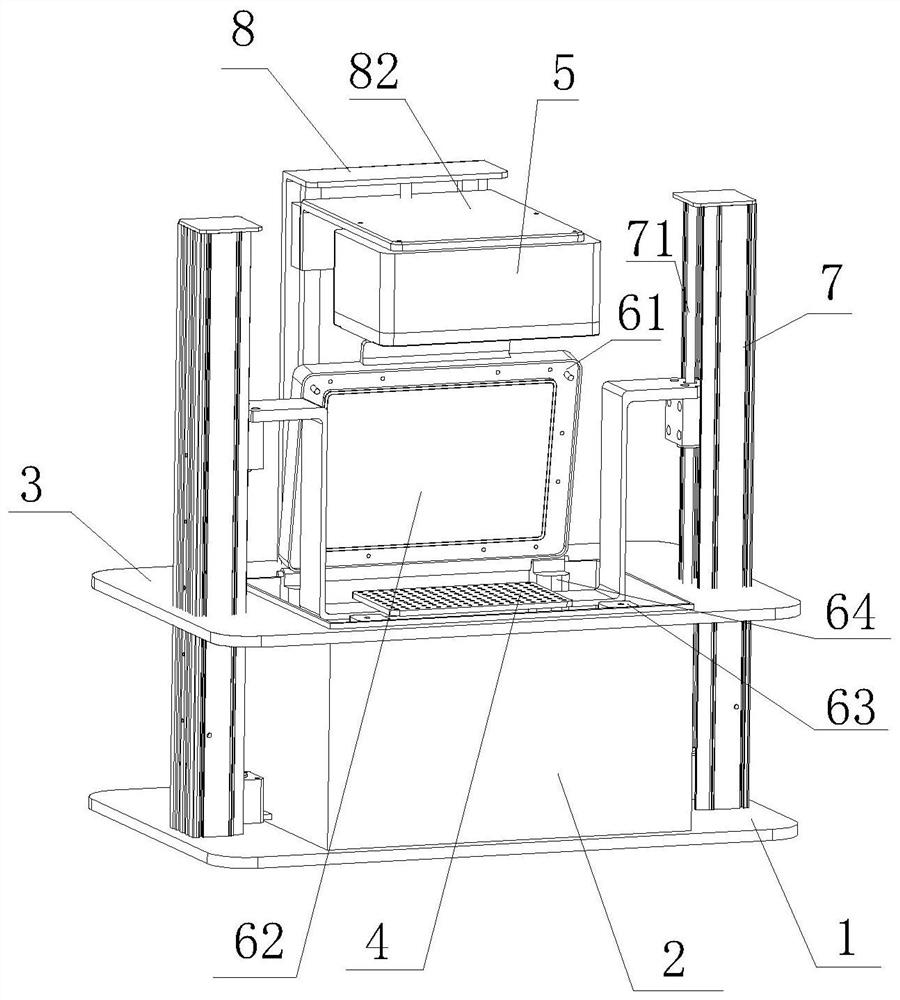

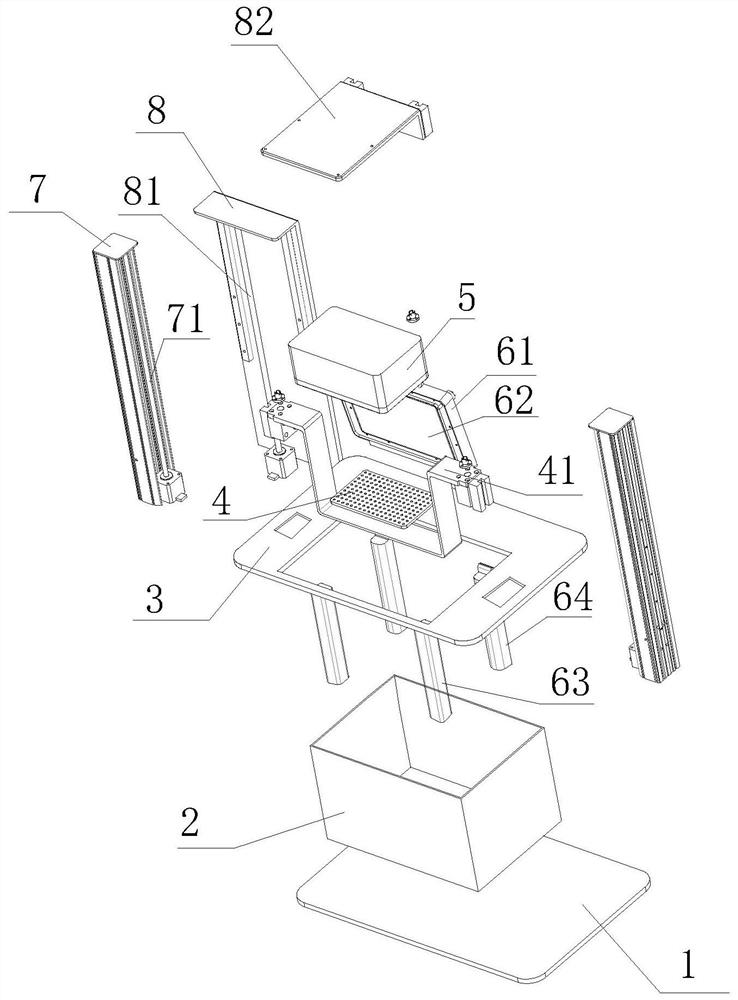

[0028] combined with figure 1 - attached Figure 7 , the present invention provides a sunken 3D printer forming system, which is characterized in that it includes a base 1, and the base 1 is provided with a material cylinder 2 containing printing materials, and the upper end of the material cylinder 2 is provided with an upper fixing seat 3. The material cylinder 2 is provided with a molding platform 4 that can move up and down, and the top of the material cylinder 2 is provided with an exposure module 5 that can move up and down. The device A for printing the surface tension of the material, the exposure module 5 is provided with a light source, the exposure module 5 is located above the material cylinder 2 and does not directly contact the material cylinder, the printing material is cured after the light is irradiated, and the forming platform moves downward to complete a layer of printing , because the exposure module 5 can move up and down, when printing, through the sunk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com