Image sensor and manufacturing method thereof

An image sensor and photosensitive unit technology, applied in the field of image sensors, can solve problems such as reducing image quality and reducing operating speed, and achieve the effects of increasing the photosensitive area, increasing the operating speed, and increasing the effective channel width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0164] In order to increase the corresponding speed of the image sensor, the response speed of the image sensor can be improved by increasing the operation speed of the row selection device, the source follower device, and the reset device in the image sensor chip. Therefore, the operating speed of the above three devices can be increased by reducing the feature size of the integrated circuit, thereby increasing the response speed of the image sensor.

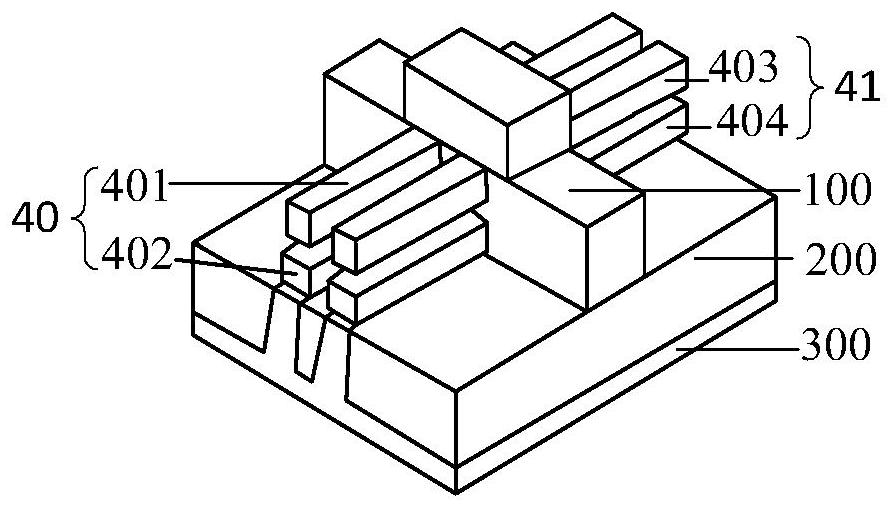

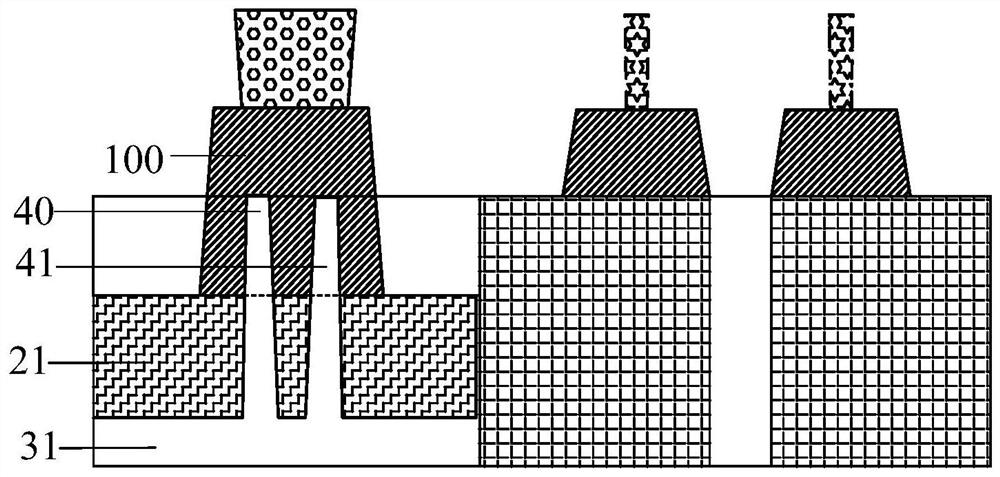

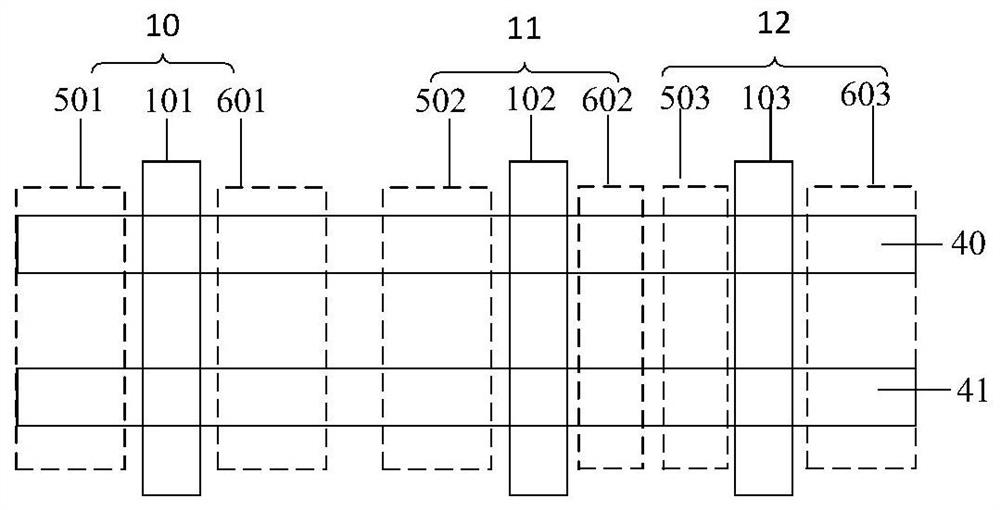

[0165] Figure 6 shows a pixel unit, Figure 7 A pixel array is shown. In the image sensor, since the photosensitive element can only sense the intensity of light and cannot capture color information, the image sensor also includes a color filter located above the photosensitive element. In some examples, red, green and blue color filters can be used to cover four different photosensitive elements respectively, wherein the red filter covers the first image point, the blue filter covers the second image point, A green filter co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com