Liquid absorbing floating ball device for oil-water separation

An oil-water separation and liquid flotation technology, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve problems such as difficulty, air suction, limited efficiency, etc., achieve simple production and processing, continuous separation process, and speed up the reaction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0036] In the present invention, "upper" and "lower" refer to the orientation of components in the use state of the device.

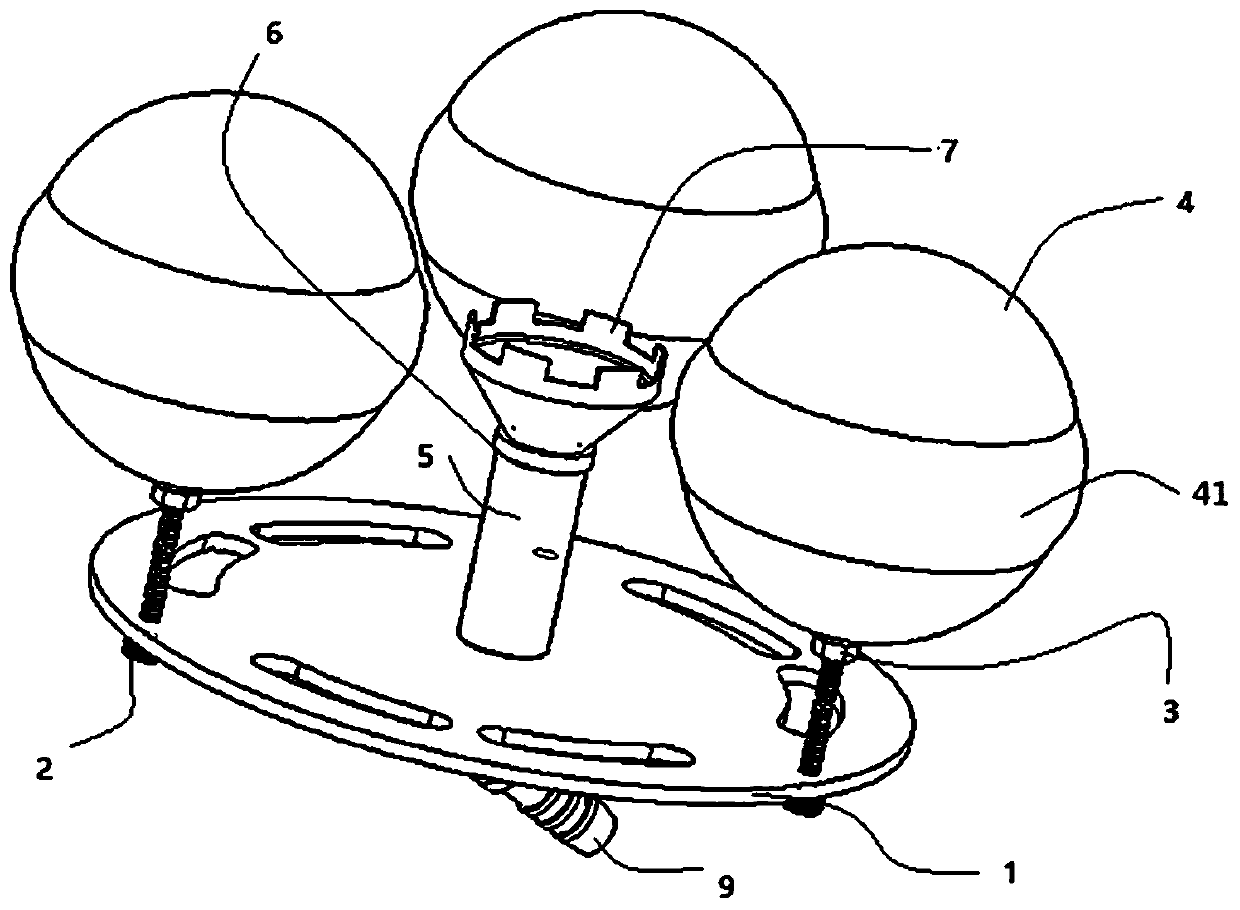

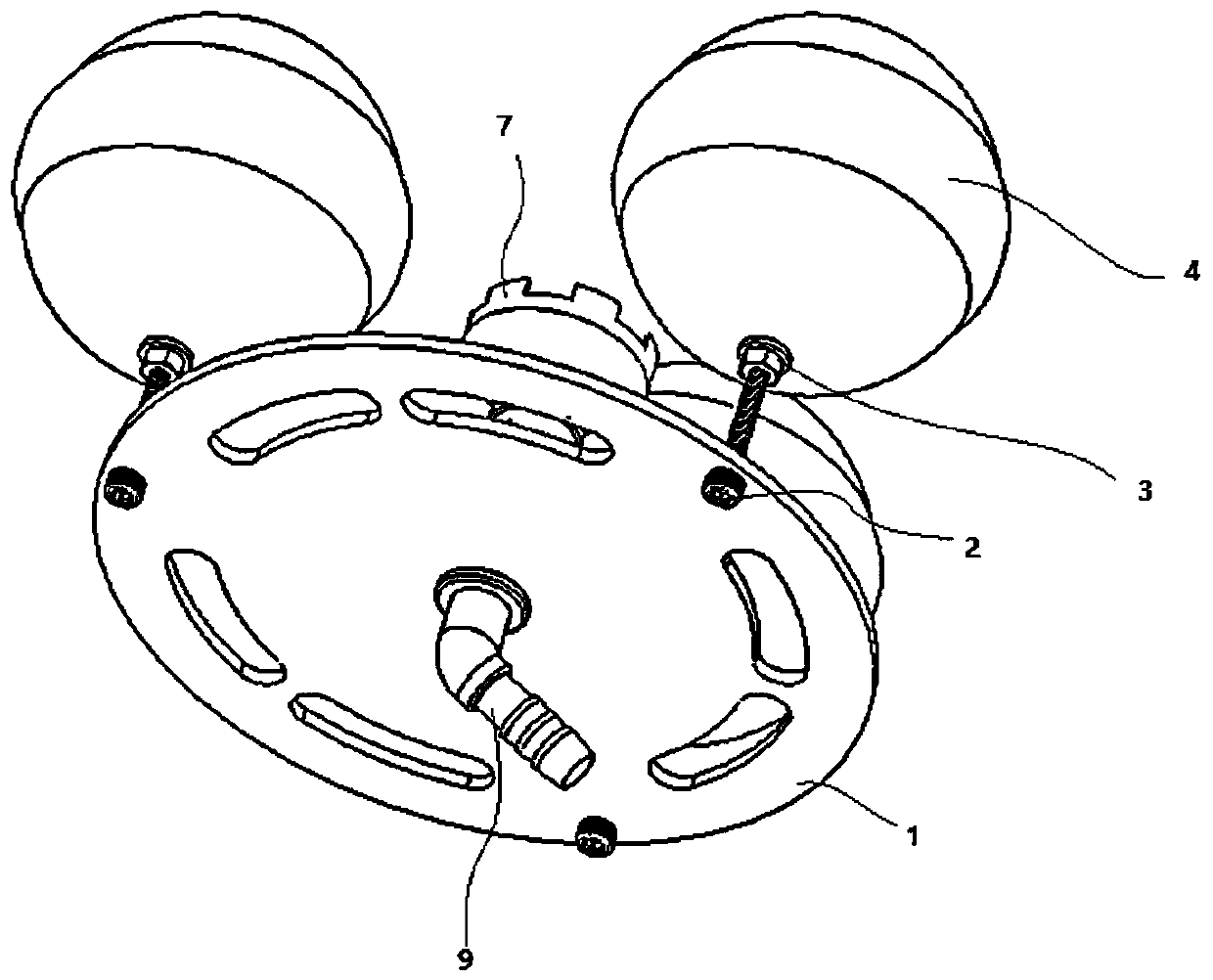

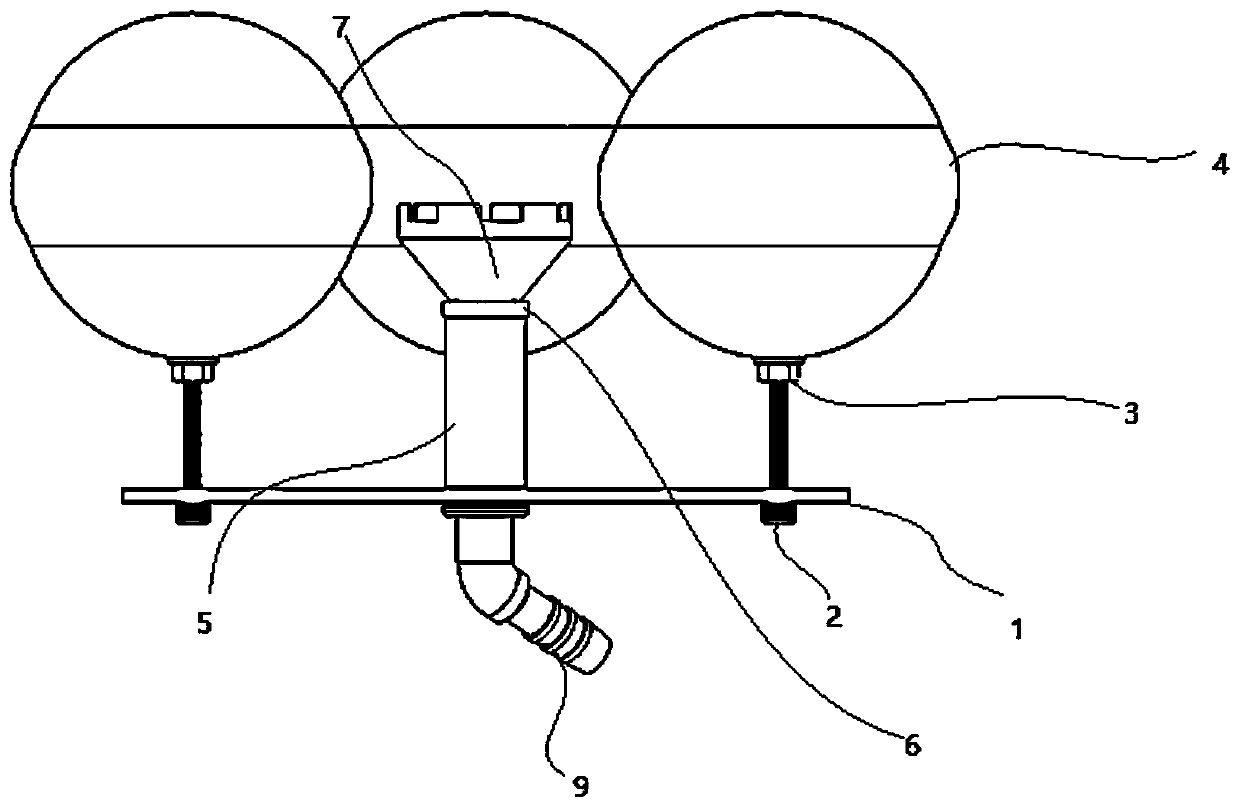

[0037] The device of the present invention includes two parts of floating ball oil-water separation and electric suction.

[0038] like Figure 1 to Figure 5 As shown, the device of the present invention comprises a disc-shaped bottom plate 1 , three floating balls 4 evenly distributed on the outer side of the bottom plate 1 , and the floating balls 4 are bolted to the bottom plate 1 . An oil-water separation chamber is pierced through the middle of the bottom plate 1, and the bottom end of the oil-water separation chamber is communicated with the suction conduit 10 (see Figure 9 and Figure 10 ), the suction conduit 10 is connected with a flow regulating valve 12 for regulating its flow (see Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com