Prefabricated acid-resistant concrete cover plate plastic mold

An acid-resistant concrete and cover plate technology, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of acid-resistant concrete with high viscosity, difficult to control demoulding time, and low molding accuracy, and achieve good dimensional stability, Simple structure and the effect of saving mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

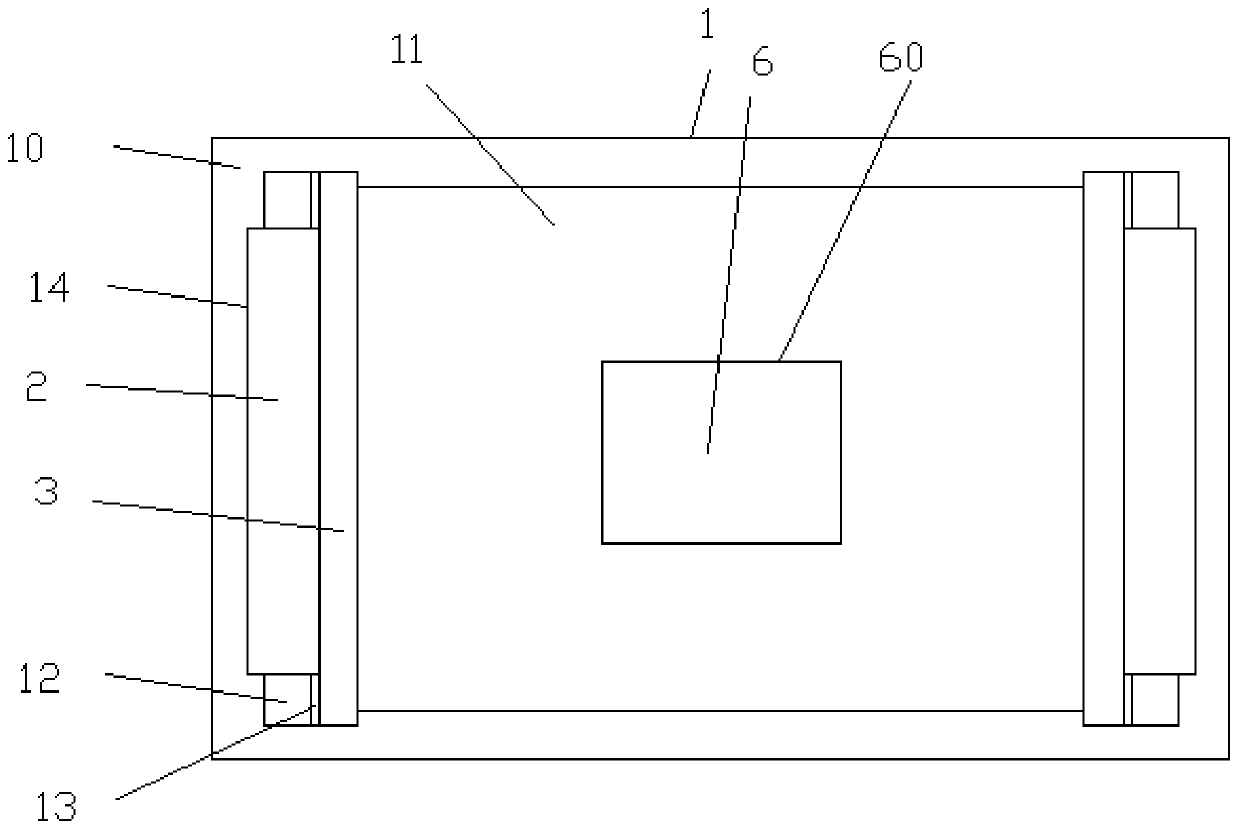

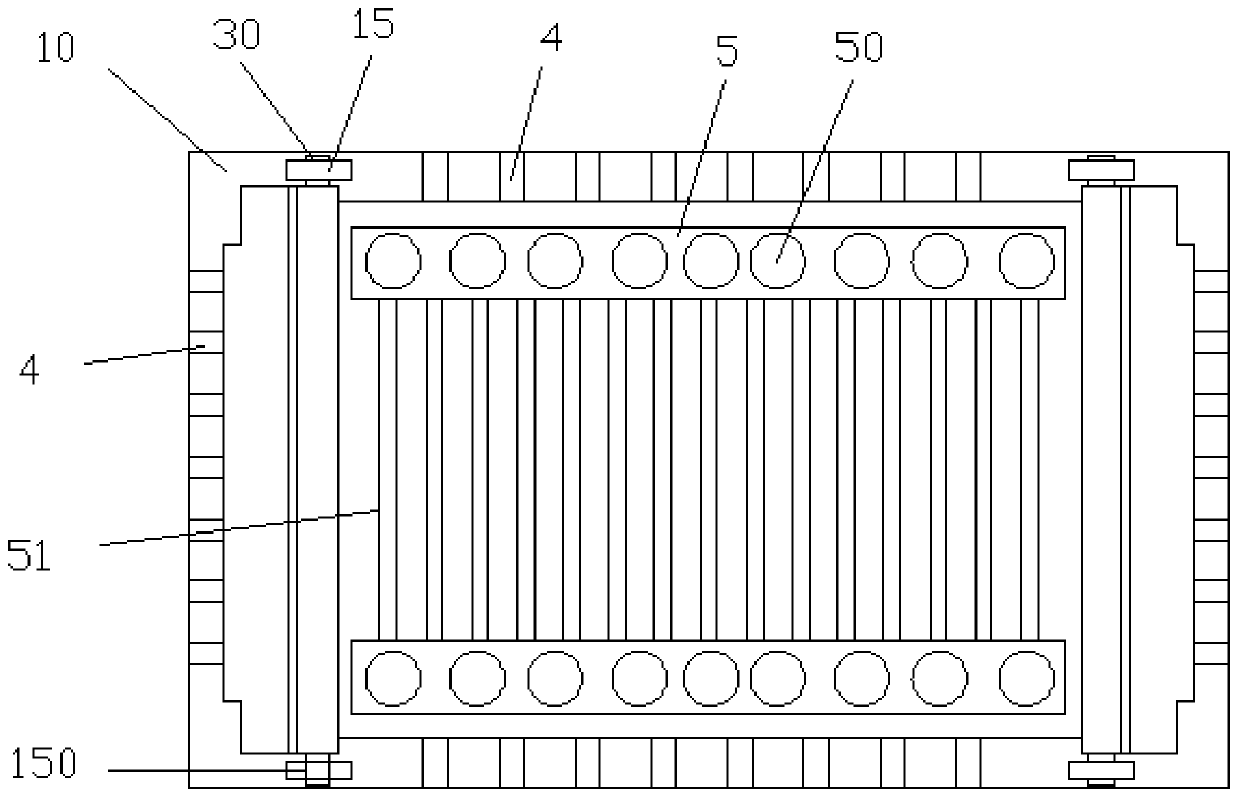

[0023] See attached figure 1 and 2 , a prefabricated acid-resistant concrete cover mold of the present invention, including a mold body 1, a support plate 2, a movable rotating plate 3, a reinforcing rib 4 and a base 5, and the mold body 1 also includes a frame 10, a mold groove 11, a side Side groove 12, through hole 13, support plate slot 14 and card insert 15, described mold body 1 is provided with mold groove 11, and described mold groove 11 outside is provided with frame 10, and described mold groove 11 left and right sides are provided with There are symmetrical side slots 12, the inner half of the side slots 12 are provided with through holes 13, the front and rear sides of the back of the side slots 12 are provided with card inserts 15, and the movable rotating plate 3 passes through the card slots. The insert 15 is installed inside the through hole 13, and can rotate within a certain angle along the through hole 13. The outer side wall of the side groove 12 is provid...

Embodiment 2

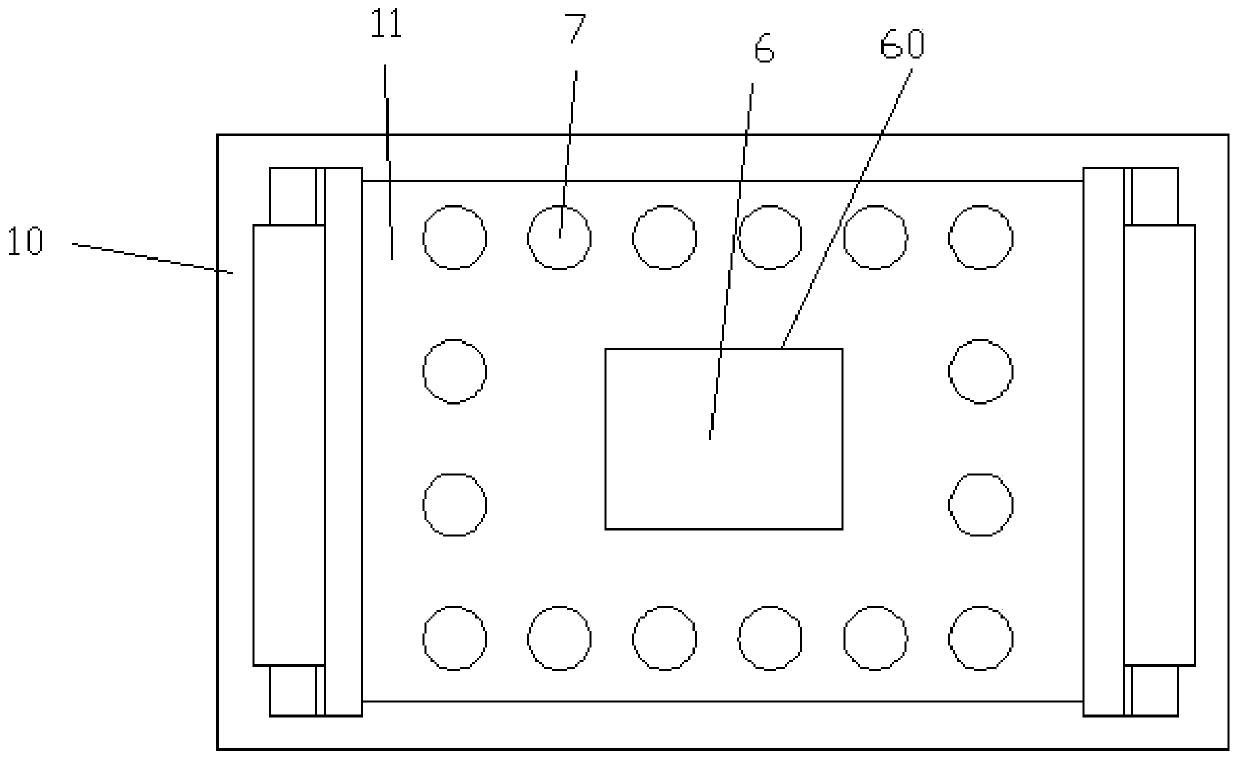

[0032] refer to image 3 In this embodiment, on the basis of implementation 1, evenly distributed circular grooves 7 are arranged on the outside of the pattern reservation groove 6, and the circular grooves 7 can play the role of anti-slip and aesthetic appearance.

Embodiment 3

[0034] refer to Figure 4 In this embodiment, on the basis of implementation 1, evenly distributed bosses 8 are arranged outside the pattern reserved groove 6, and mutually symmetrical bosses 16 are arranged on the front and rear side walls of the frame 10, and the bosses 8 will be placed on the Holes are left on the relative position of the prepared cover plate to facilitate the flow of sewage into the sewage hole below the cover plate, and the boss 16 makes the prepared cover plate have two corresponding gaps on the front and rear sides, further increasing the The sewage discharge capacity of the cover plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com