Centre-type stepless speed regulating stranding machine

A technology of stepless speed regulation and hemp stranding machine, which is applied in textiles, papermaking, rope-making auxiliary devices, textile cables, etc., to reduce labor intensity and reduce the effect of I-shaped wheel movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

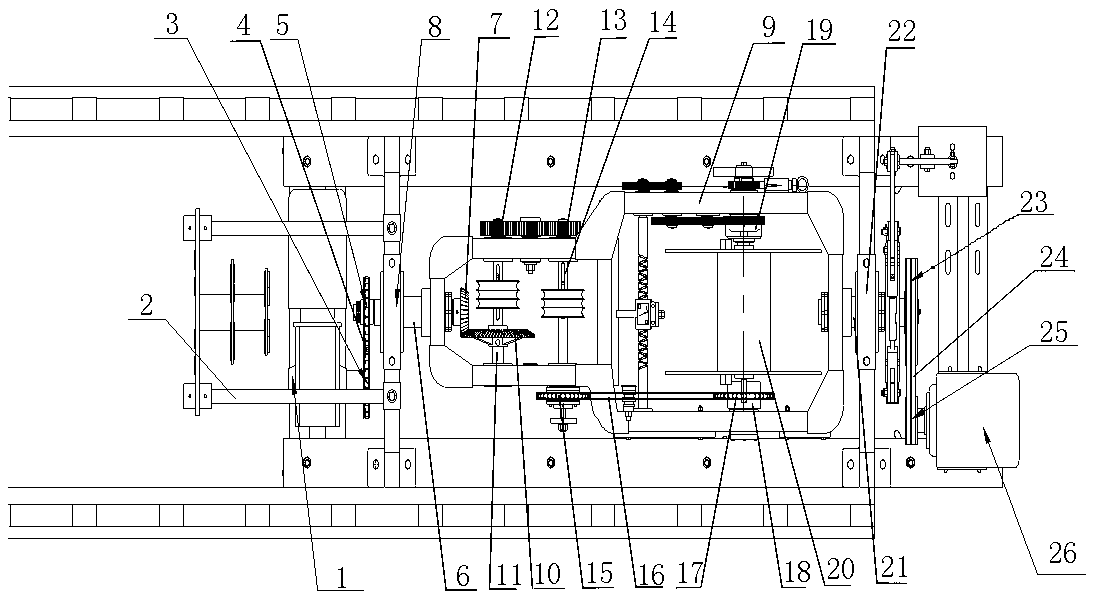

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

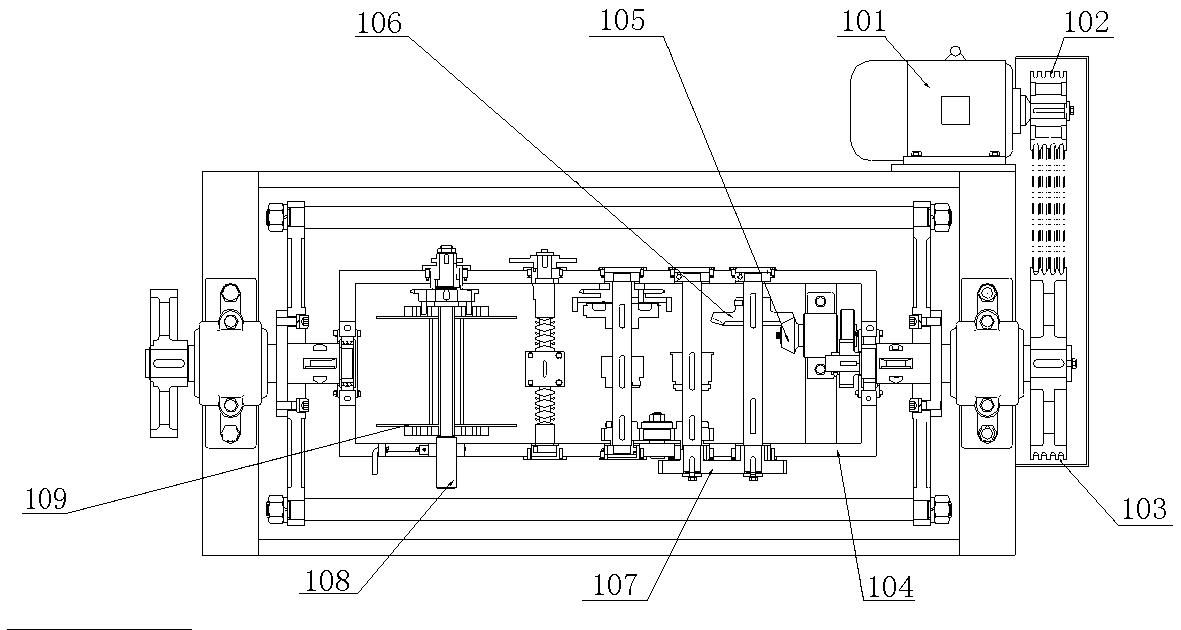

[0017] Top stepless speed regulation hemp stranding machine, such as figure 2 As shown: it includes motor A1, bracket 2, small sprocket 3, chain 4, large sprocket 5, rotating shaft A6, gear A7, rotating shaft seat A8, frame A9, gear B10, rotating shaft B11, gear C12, gear D13, rotating shaft C14, pulley A15, belt A16, pulley B17, mobile top device 18, fixed top device 19, I-shaped wheel 20, rotating shaft D21, bearing seat B22, large pulley 23, belt B24, small pulley 25, motor B26; The motor A1 is located on the support 2; the motor A1 is provided with a small sprocket 3, the small sprocket 3 is connected with the large sprocket 5 through the chain 4, the large sprocket 5 is arranged on one end of the rotating shaft A6, and the other end of the rotating shaft A6 is provided There is a gear A7; the middle part of the rotating shaft A5 is arranged on the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com