Method and apparatus for generating superficial structure

A three-dimensional surface, embossing technology, applied to the device for coating liquid on the surface, special surface, pretreatment surface, etc., can solve problems such as embossing that is not easy to obtain alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

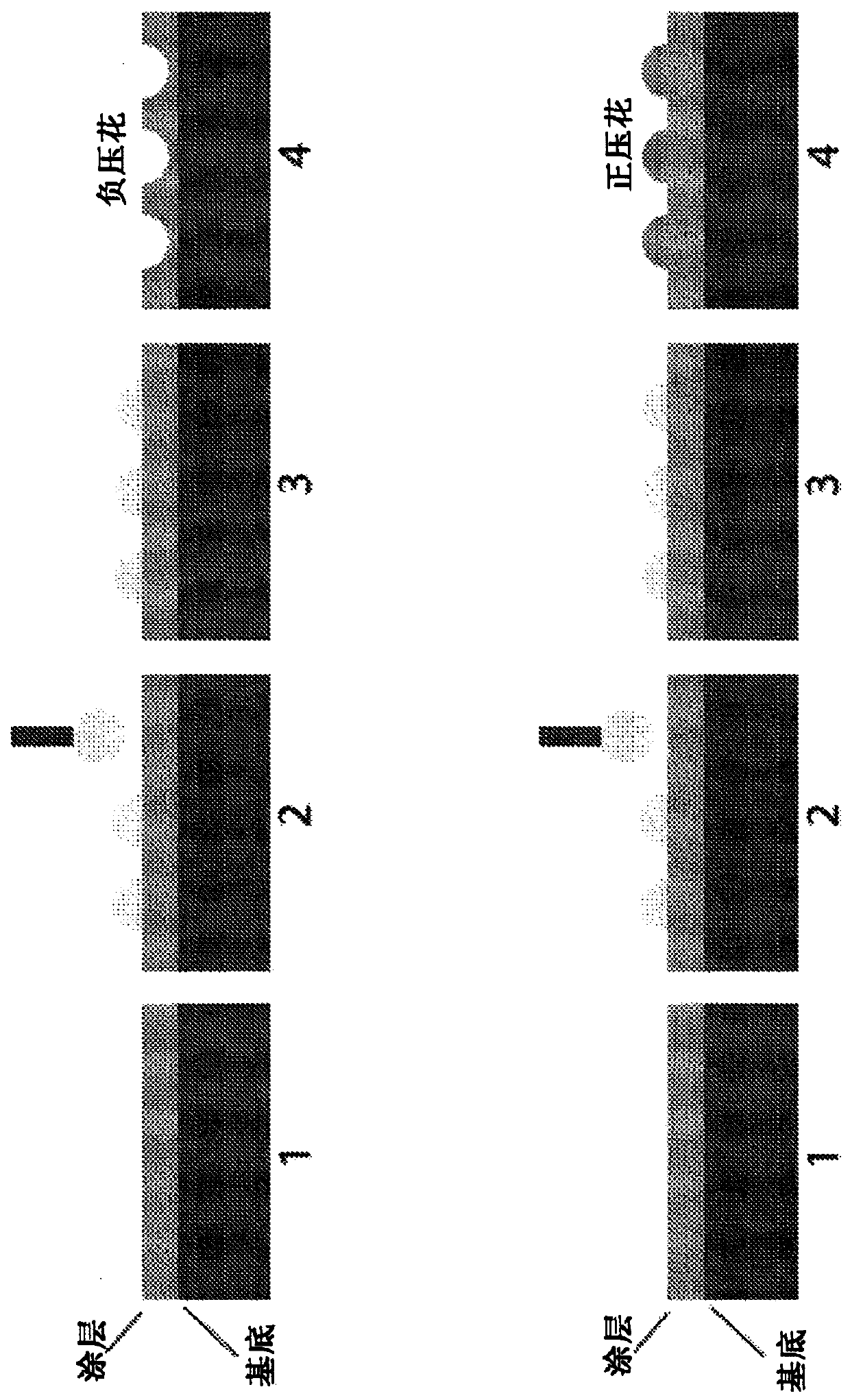

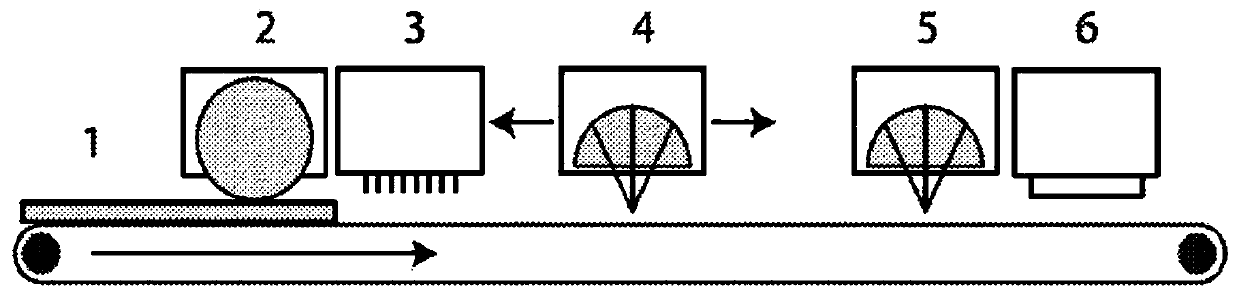

Method used

Image

Examples

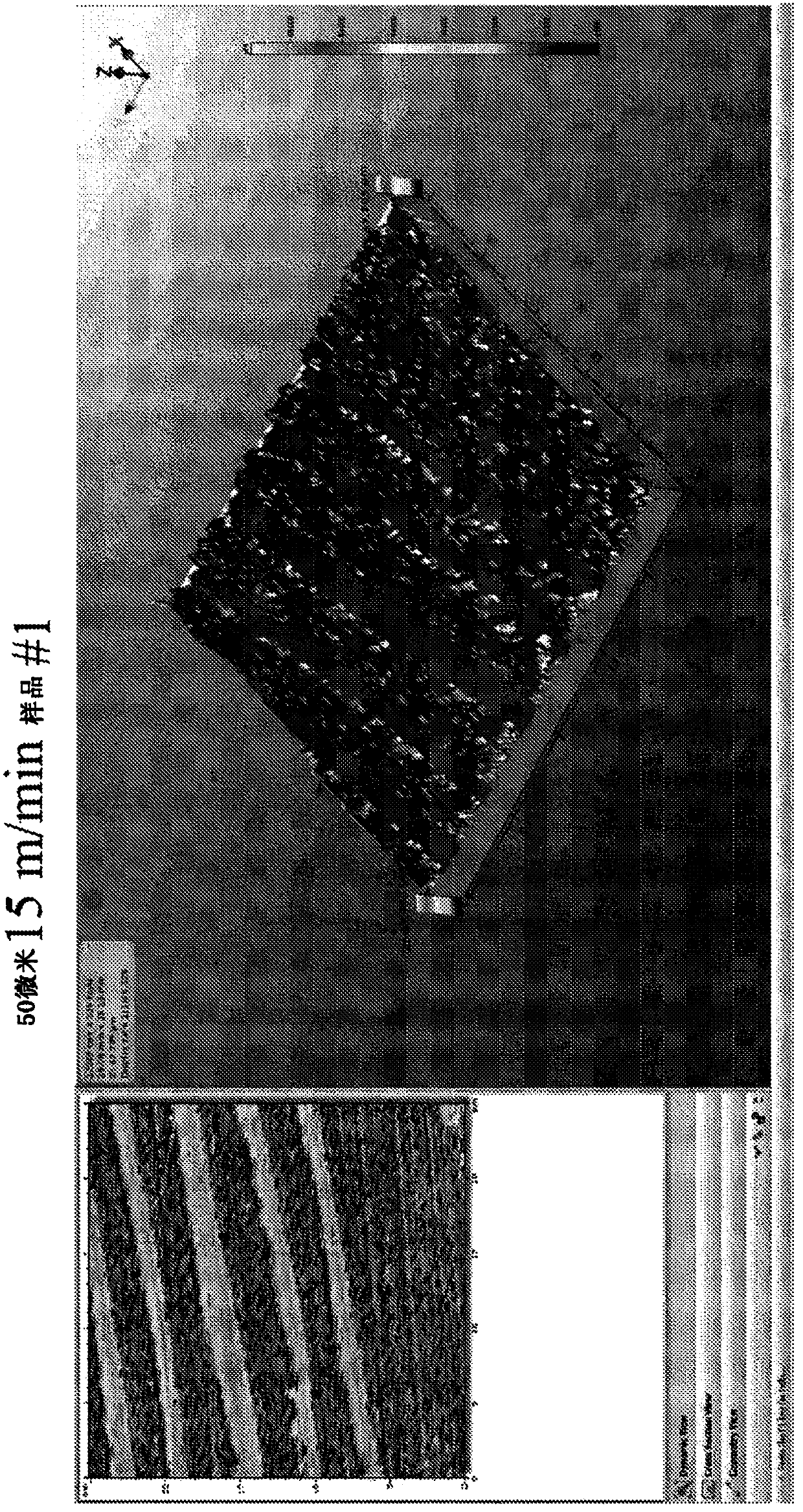

example 1

[0080] 50 g / sqm of photocurable paint (Renner UO-240) for finishing the floor was applied consistently to the MDF panels by means of a paint roller at a speed of 15 m / min. Subsequently, the panel was passed under a single-pass inkjet printer, by which the coating made of H 2 Embossing fluid composed of O+2% TEGO RAD 2100 (acrylate polysiloxane). After application, the convexity produced by the embossing fluid on the paint becomes apparent. The printing machine used (CEFLA) was equipped with a DIMATIX STARFIRE 1024 printing head, and the printed images were obtained by three-dimensional scanning using a scanner of natural oak sections (METIS). The image is then uploaded to the printing press with the aid of special software (RIP). Subsequently, the panel was irradiated with 160 w / cm ultraviolet light generated by a medium pressure Hg lamp. In addition to the UV light beams, the lamps also generate heat, which in this case is sufficient to evaporate the water contained in the...

example 2

[0082] A photocurable gray varnish (100 g / sqm) was applied to the support material. Subsequently, the support was passed under a single-pass inkjet printer equipped with a DIMATIX STARFIRE 1024S print head, by which the H 2 Embossing fluid composed of O. The support was then irradiated with 160 w / cm UV light generated by a medium pressure Hg lamp. On the surface, a typographic image made of text with variable fonts is quite apparent.

example 3

[0084] A high gloss photocurable coating (Renner UO-240) was applied to the support material.

[0085] The carrier was passed under a single-pass type inkjet printer equipped with a DIMATIX STARFIRE 1024S printhead with a minimum droplet size of 10 pl, through which only the smallest droplet was applied by H 2 Embossing fluid composed of O. Then immediately use 395nm 8w / cm 2 The carrier was irradiated with a PHOSEON FIRELINE lamp, and then the carrier was irradiated with a medium pressure DR of 160w / cm. A Hg lamp completes the polymerization of the paint. The coating is evenly matted thanks to the microstructure created by the microdroplets laid down by the inkjet print head. The original paint is actually equal to 85 gloss units, and after application, the paint is equal to 35 gloss units.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap