Plate-making method for one-piece type lapel

A lapel, one-piece technology, applied to the plate making field of one-piece lapel, can solve the problems of easy arching of the front body, poor conformity, and incompatibility, and achieves sewing time saving, clear boundaries, The effect of labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

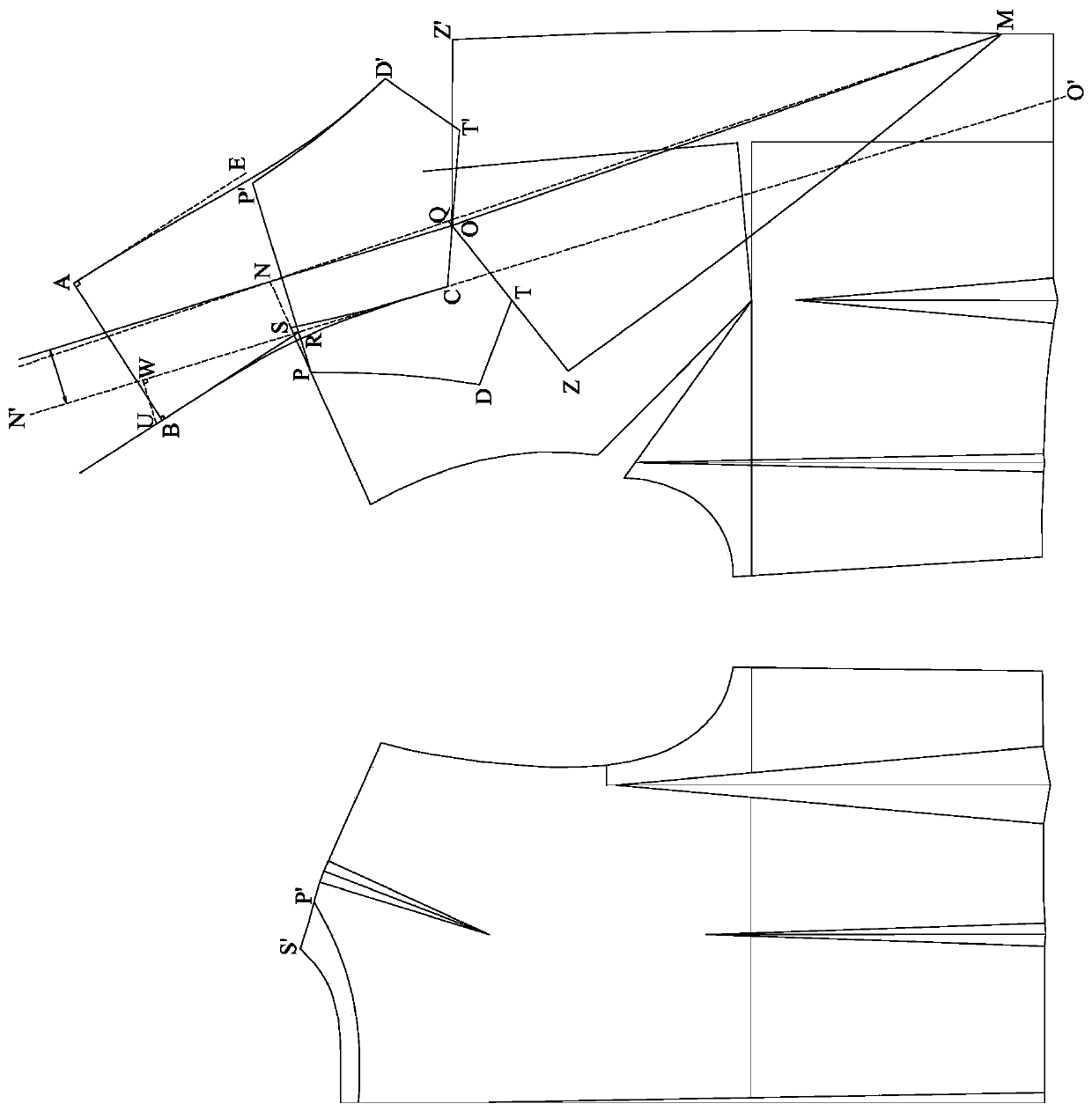

[0038] Such as figure 1 As shown, the plate-making method of the one-piece lapel collar of the present embodiment, the plate-making method comprises the following steps:

[0039](1) Define the collar seat height of the one-piece lapel collar as a=3.5cm, the collar width as b=5.5cm, the back collar arc length as k, and the length unit as cm;

[0040] In the body structure diagram, extend 0.7a along the shoulder oblique line from the front neck width point S to the front horizontal open neck point N (that is, the length of the line segment NS is 0.7a), connect the N point and the barge point M, and determine the original folding line MN ;

[0041] Extend the original folding line MN at will, as the basic line of this plate-making;

[0042] (2) Reasonably design the shape of the lapel in the body structure diagram, and at the same time retrieve b from point N along the shoulder oblique line to obtain the shoulder seam point P (that is, the length of the line segment NP is b). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com