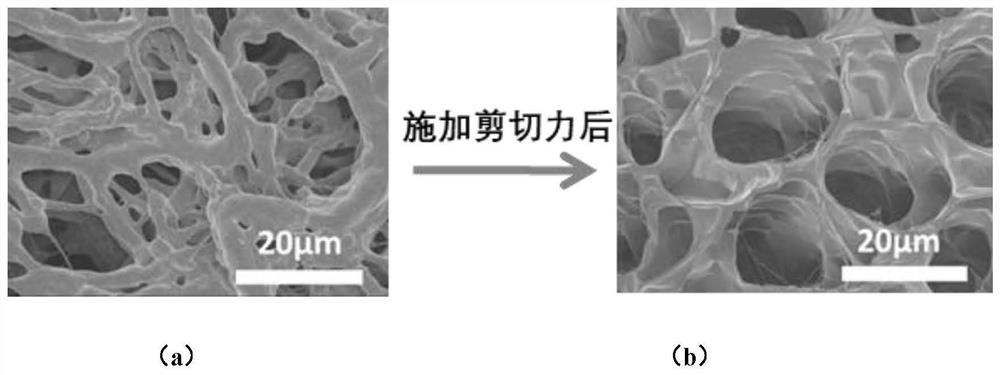

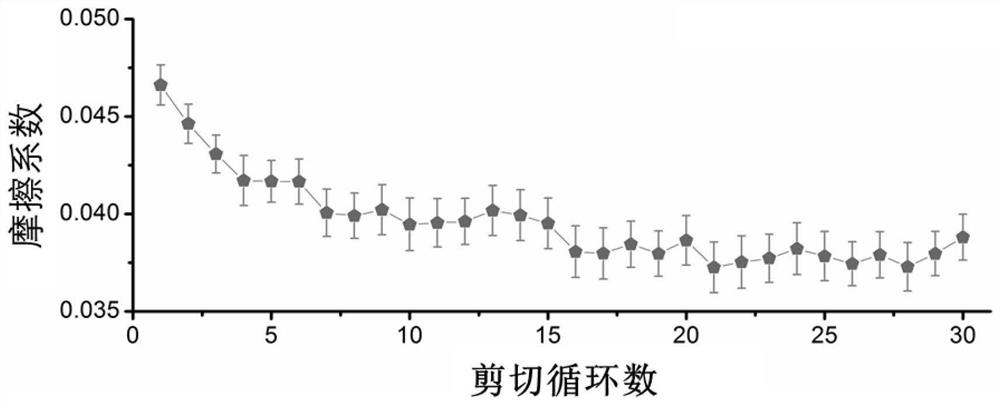

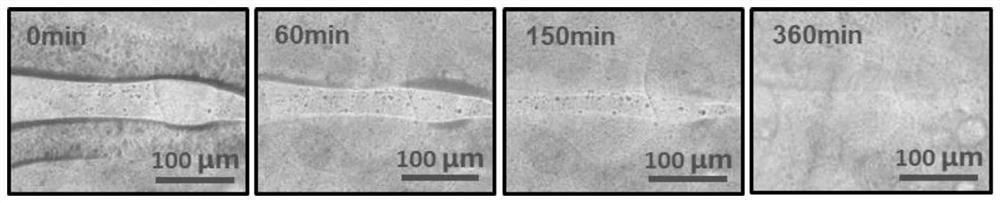

A shear force-responsive supramolecular biomimetic articular cartilage material with dynamic lubrication and self-healing ability and preparation method thereof

A dynamic lubrication, bionic joint technology, applied in tissue regeneration, pharmaceutical formulations, prostheses, etc., can solve the problems of loss of physiological lubrication function, damage of arched fiber network structure, increase of friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Measure 50 mL of hydroxyethylacrylamide in a conical flask, then weigh 5 g of monomer polyvinyl alcohol powder and add it to the above solution, add crosslinking agent glutaraldehyde and initiator ketoglutaric acid to the solution, crosslink The final concentrations of the coupling agent and the initiator were both 0.5 μg / mL, and the solution was mixed evenly by magnetic stirring (800 r / min) for 50 min.

[0020] (2) Take 40 mL of the solution prepared in step (1), add 60 mg of fluorenylmethoxycarbonyl-L-tryptophan; magnetically stir at 85 °C for 3 h to dissolve the monomer; after dissolving, cool the solution to room temperature, A solution with a concentration of fluorenylmethoxycarbonyl-L-tryptophan of 1.5 mg / mL was obtained, and the above solution was exposed to ultraviolet light for 5 h to form a gel, and the surface of the sample was washed with deionized water to remove residual monomers, and the obtained hydrogel was the The shear force-responsive supramolecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com