A New Type of Hydraulic Rotary Oil Distribution (Oil Supply) Device

A technology of oil distribution device and hydraulic rotation, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of internal oil and sediment, skeleton oil seal leakage, spline shaft wear and other problems, and achieve saving The effects of maintenance man-hours, effective lubrication, and superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiment:

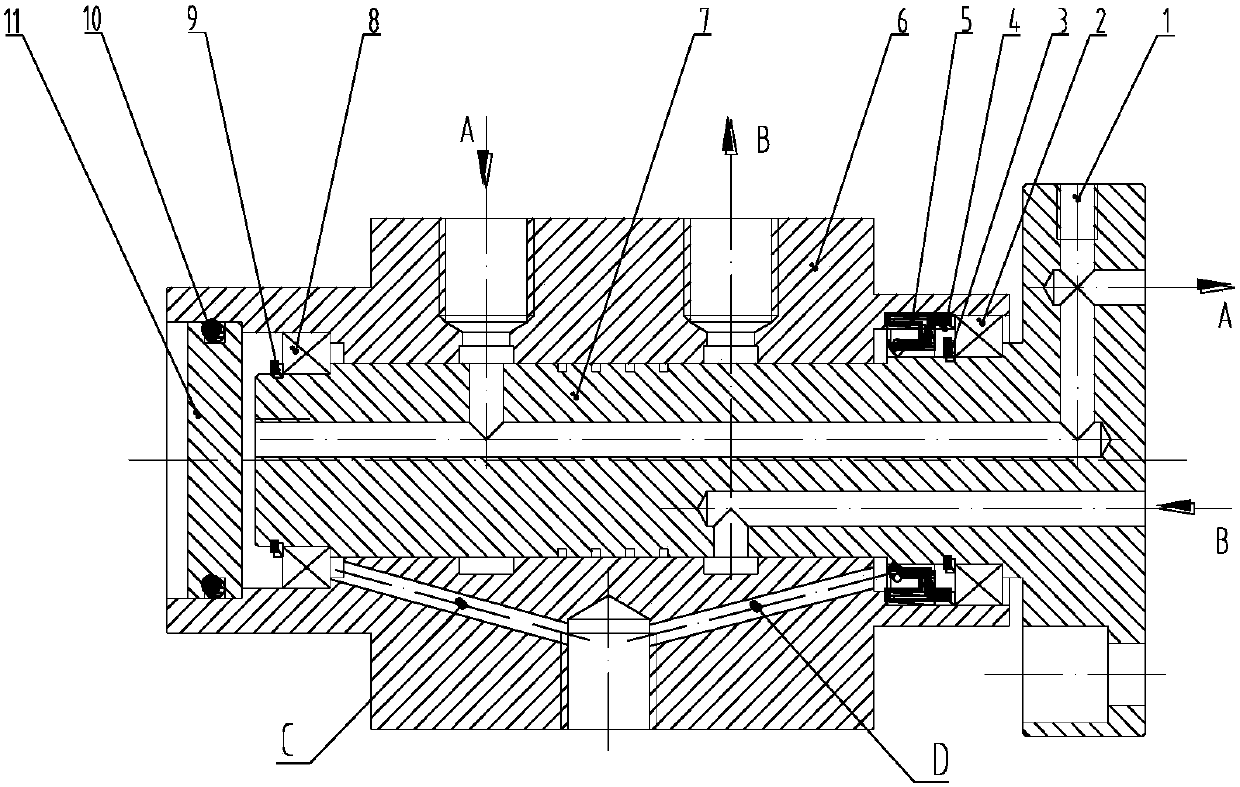

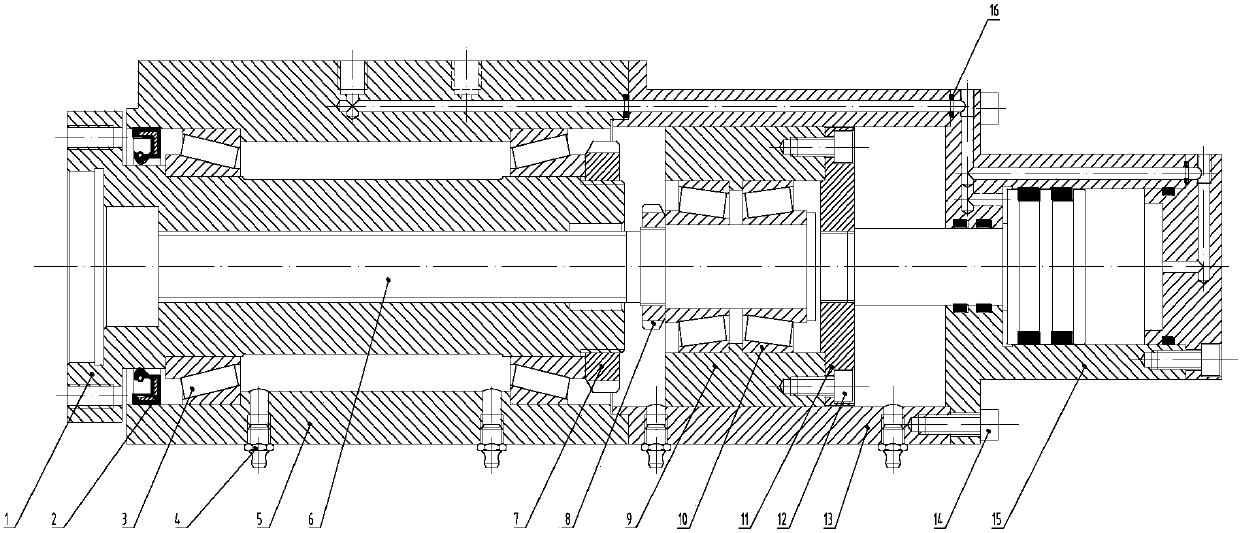

[0021] Such as figure 1 A new type of hydraulic rotary oil distribution (oil supply) device shown includes a main shaft 7, a shaft sleeve 6 and an end cover 11. The two ends of the main shaft are provided with bearing I2 and bearing II8, and the bearing I2 and bearing II8 pass through the elastic stopper for the shaft respectively. Ring Ⅰ3 and elastic retaining ring Ⅱ9 are used for axial positioning of the bearing; oil passage holes A and B are designed and processed on the main shaft 7 to connect with the rotary hydraulic cylinder, and the processing holes are blocked by screw plug 1, which can store hydraulic oil Impurities in the medium and small abrasive particles worn by parts can delay the wear between the main shaft 7 and the sleeve 6 and prolong the service life; the middle part of the main shaft 7 is designed with four chip pockets, and the main shaft 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com