A self-lubricating low temperature rise harmonic reducer and preparation method thereof

A harmonic reducer and self-lubricating technology, which is applied in the field of mechanical equipment manufacturing, can solve the problems of dry friction, hard cast structure, short life, etc., achieve high acceleration torque and instantaneous acceleration torque, and excellent self-lubrication function , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

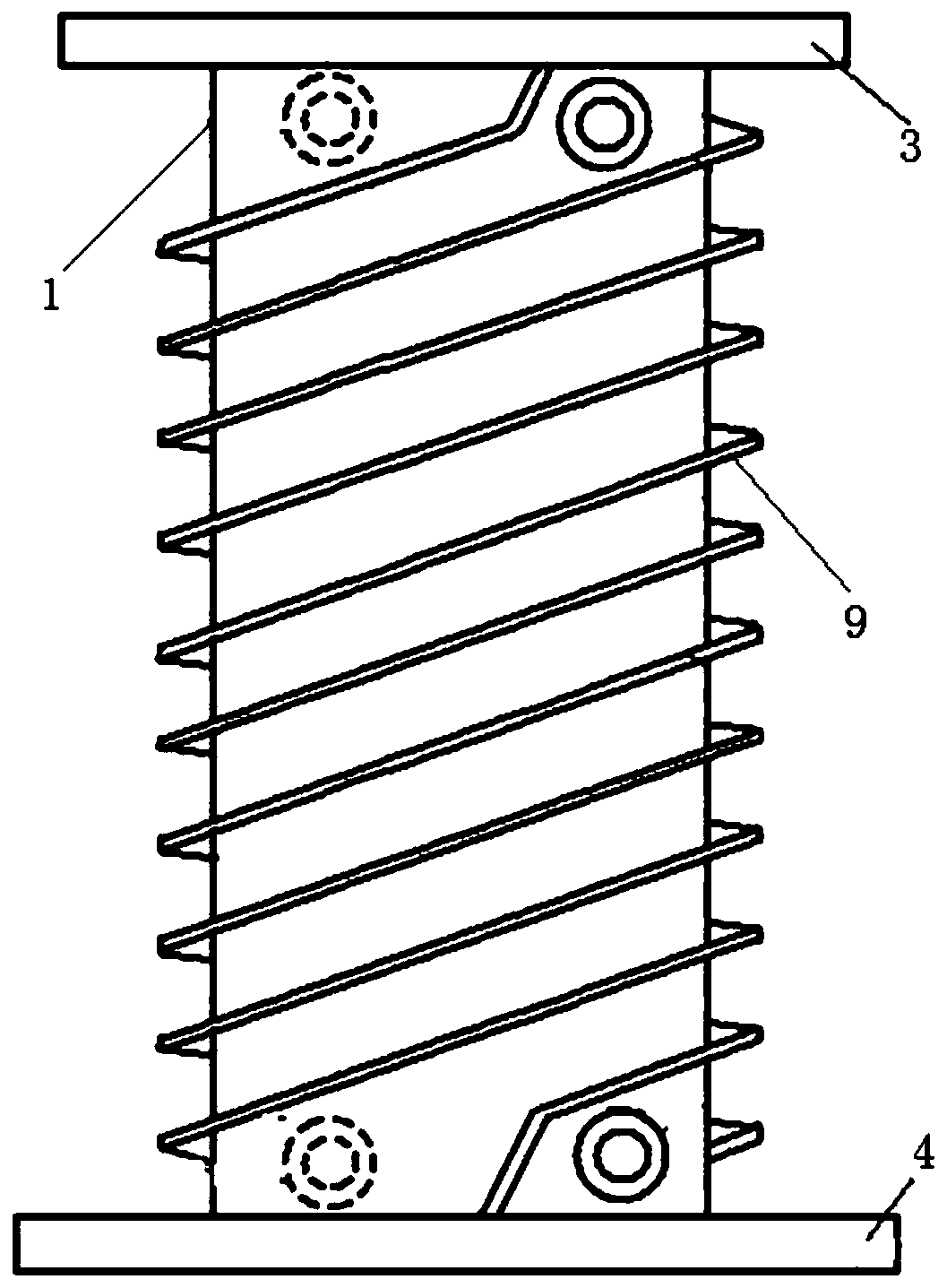

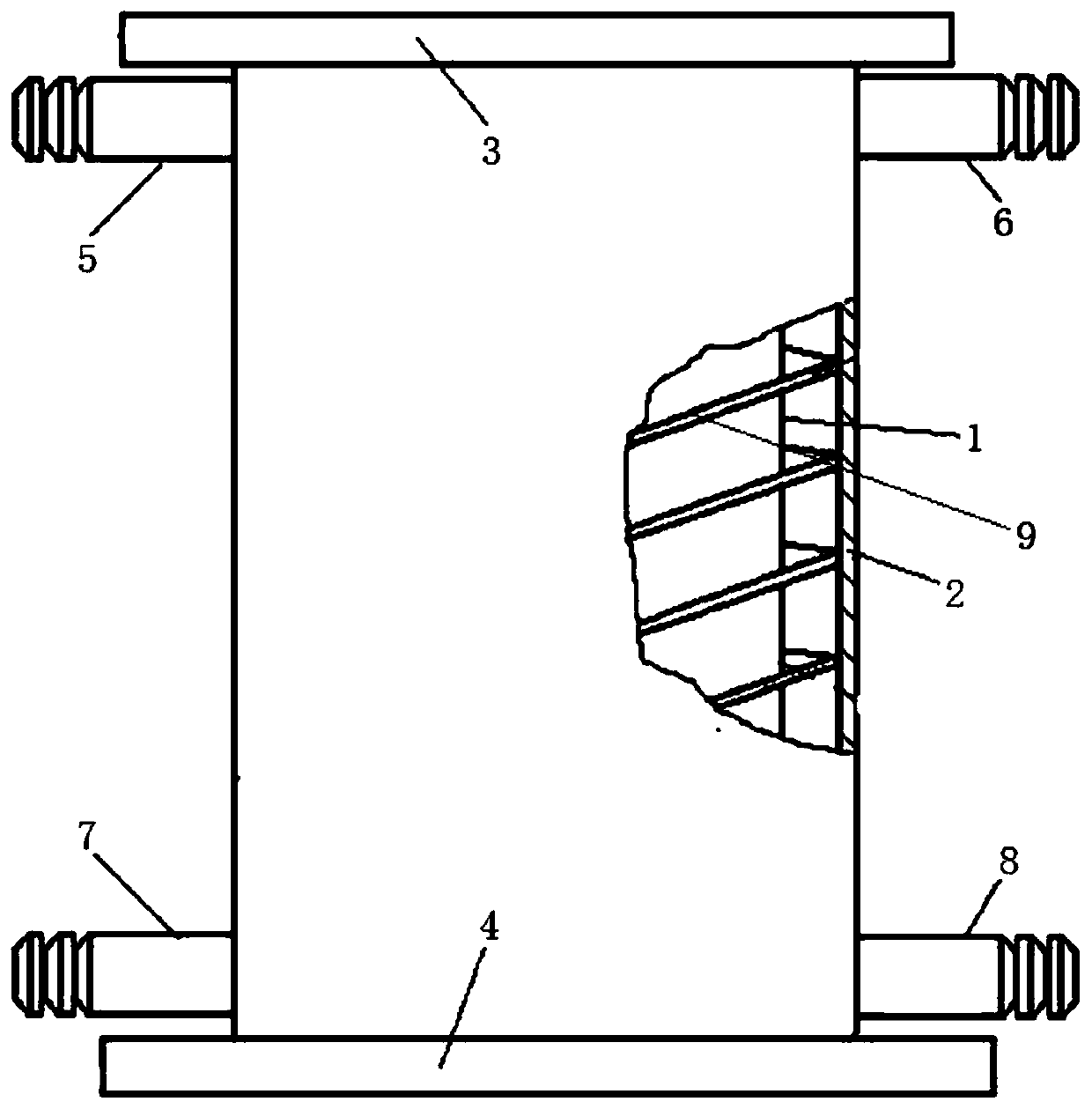

[0049] The present invention also provides a preparation method for the above-mentioned harmonic reducer, which is described in the patent "Continuous Casting Equipment for Low Plasticity Metal Hollow Profiles" (Patent No.: ZL200710018928.2, Publication No.: 101134231, Publication Date: 2008-03- 05) on implementation. The difference with the original device is that the structure of the crystallizer in the original device is different from that of the crystallizer in the present invention, such as Figure 1~2 As shown, its structure is as follows: it includes an inner cylinder 1 and an outer cylinder 2 that are nested with each other. The bottom of the outer cylinder is connected with the lower flange 4, the upper part of the outer cylinder 2 is respectively provided with water inlet I5 and water inlet II6, the lower part of the outer cylinder 2 is respectively provided with water outlet I7 and water outlet II8, and the inner cylinder The outer circle of 1 has a double-helix r...

Embodiment 1

[0078] Step 1, using bread pig iron, scrap steel and ferroalloy materials, configure the molten iron components according to the mass percentage: C: 3.4%-3.7%, Si: 1.5%-1.7%, Mn: 0.3%-0.5%, Cr: 0.3%-0.5% %, S≤0.05%, P≤0.05%, Fe is the balance, the sum of the mass percentages of the above components is 100%, and the above materials are melted into molten iron, and the final silicon content of the molten iron is 2.7 through inoculation and spheroidization %-2.9%, residual magnesium content 0.03%-0.045%;

[0079]Step 2, drawing the molten iron in step 1 into hollow profiles and solid bars respectively by a vertical continuous casting method;

[0080] Step 3, detecting the metallographic structure of the hollow profile obtained in step 2 and the solid bar;

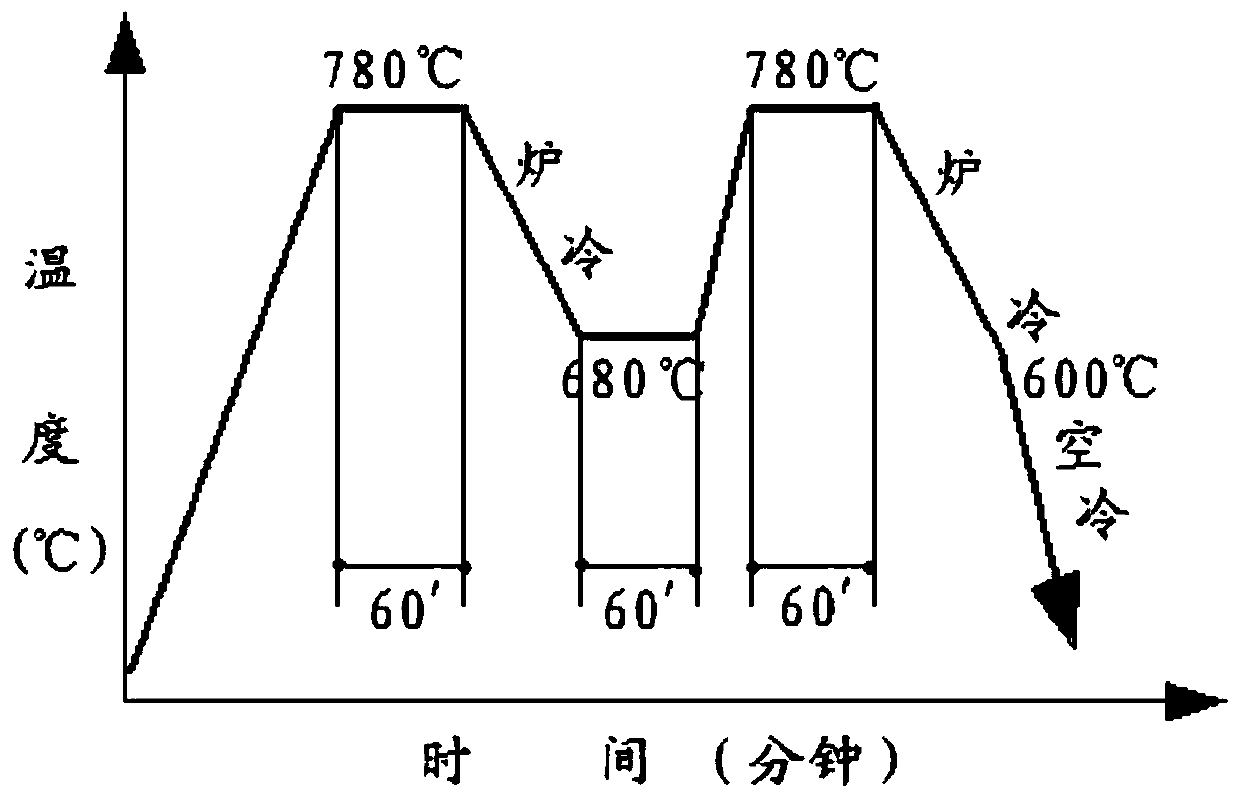

[0081] For the hollow profile of the internal tooth rigid wheel, it is necessary to ensure that the graphite spheroidization rate in the as-cast structure at a depth of 15-20 mm from the surface is ≥ 90%, the diameter of grap...

Embodiment 2

[0097] Step 1, using bread pig iron, scrap steel and ferroalloy materials, configure the molten iron components according to the mass percentage: C: 3.4%-3.7%, Si: 1.5%-1.7%, Mn: 0.3%-0.5%, Cr: 0.3%-0.5% %, S≤0.05%, P≤0.05%, Fe is the balance, the sum of the mass percentages of the above components is 100%, and the above materials are melted into molten iron, and the final silicon content of the molten iron is 2.7 through inoculation and spheroidization %-2.9%, residual magnesium content 0.03%-0.045%;

[0098] Step 2, drawing the molten iron in step 1 into hollow profiles and solid bars respectively by a vertical continuous casting method;

[0099] Step 3, detecting the metallographic structure of the hollow profile obtained in step 2 and the solid bar;

[0100] For the hollow profile of the internal tooth rigid wheel, it is necessary to ensure that the graphite spheroidization rate in the as-cast structure at a depth of 15-20 mm from the surface is ≥ 90%, the diameter of gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com