Nano self-lubricating insulating paint as well as preparation method and application thereof

A technology of self-lubricating and insulating varnish, which is applied in the direction of insulating conductors, insulating cables, and insulating conductors/cables, etc. Stability problems such as poor dielectric properties, to achieve low friction coefficient, reduce friction coefficient, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

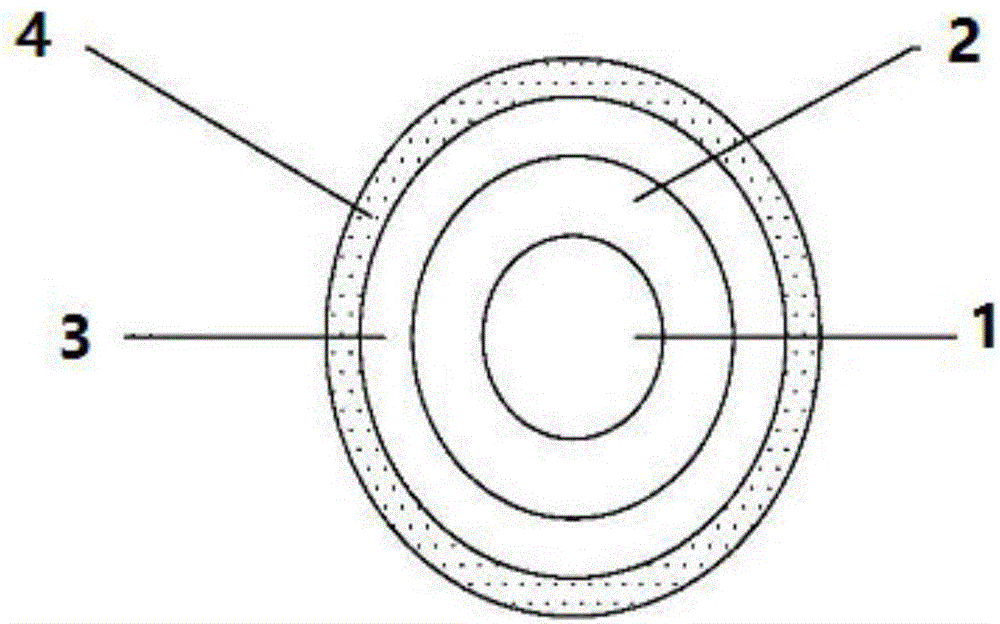

Image

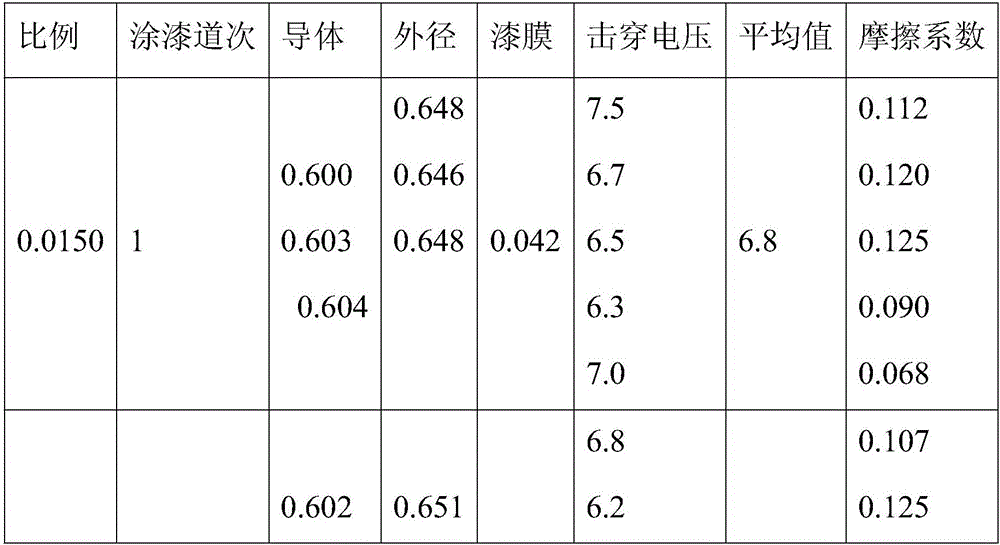

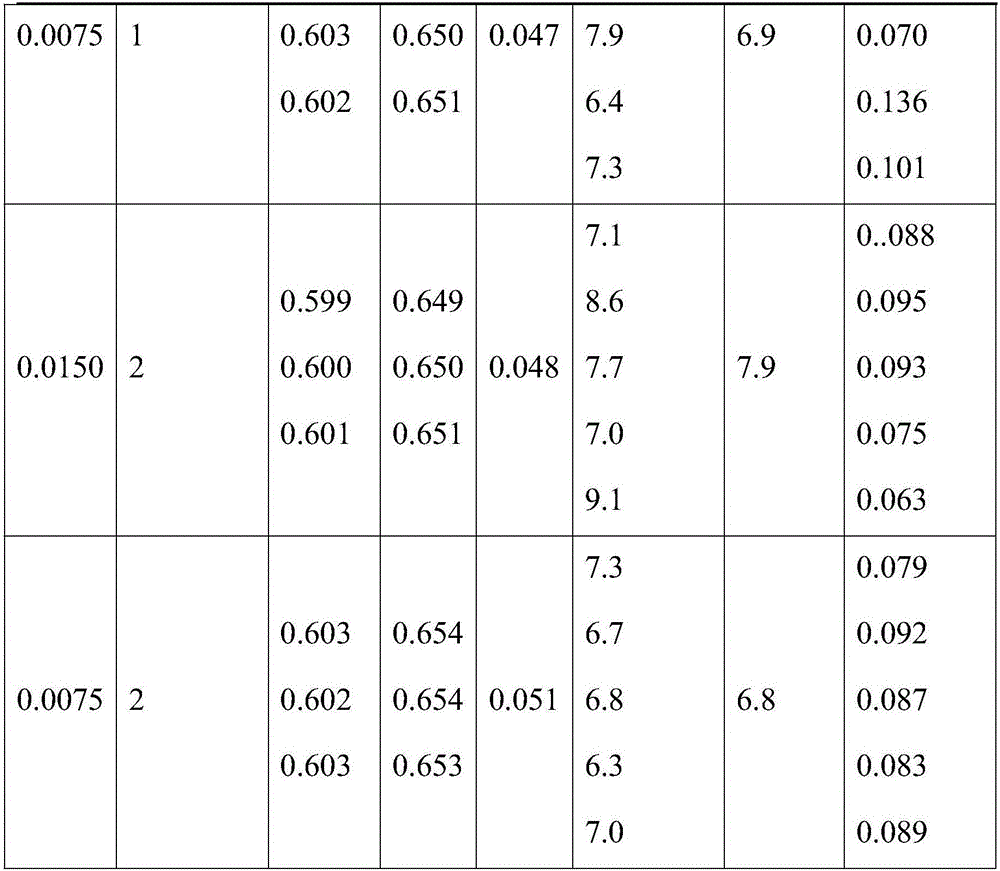

Examples

Embodiment 1

[0032] use MoS 3 Ball milling with sulfur in a ball mill, and sintering the resulting mixture in a tube furnace to obtain MoS2 nanomaterials, and then stearic acid and MoS 2 Nanomaterials are mixed, and the modified MoS with a particle size of no more than 100nm is made by ultrasonic and grinding methods 2 Nano powder, ready for use.

[0033]Add the modified molybdenum disulfide nanopowder into N-methylpyrrolidone and stir at 40-60°C for 0.5-1h to obtain MoS 2 / NMP lubricating fluid; MoS 2 / NMP lubricating liquid is added to polyamide-imide insulating varnish, and stirred at 40-50°C for 1-2 hours to obtain nanometer self-lubricating insulating varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com