Automatic scanning, measuring and analyzing device and method for engineering tire winding tread shape

An automatic scanning, measurement and analysis technology, applied in the direction of measuring devices, optical devices, tires, etc., can solve the problems of cumbersome measurement process, reduce production efficiency, waste production time, etc., achieve simple use, improve accuracy and efficiency, and reduce detection cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in combination with specific embodiments.

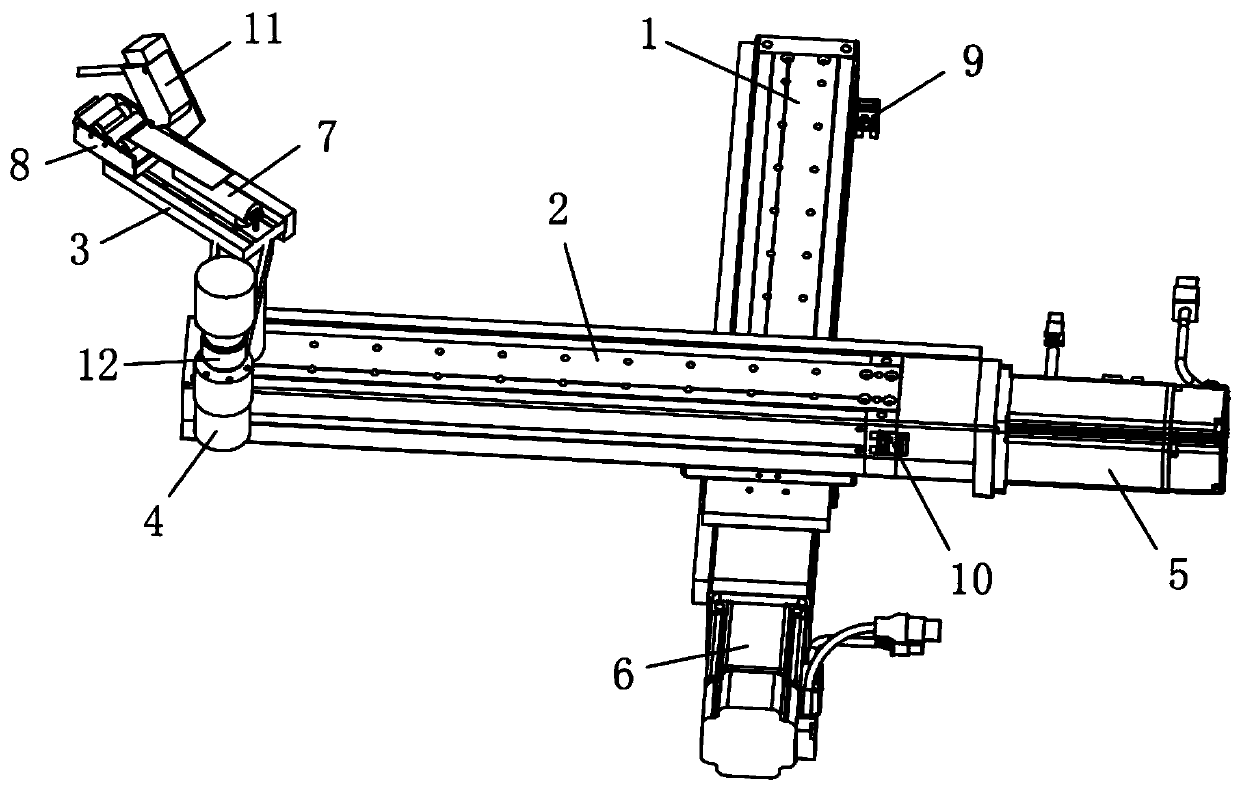

[0042] figure 1 An engineering tire winding tread shape automatic scanning measurement analysis device includes a winding machine; the winding machine includes an X-axis moving track 1 moving along the X-axis direction, a Y-axis moving track 2 moving along the Y-axis direction, and a Y-axis moving track 2 moving along the Z-axis direction. The Z-axis moving track that moves in the axial direction 3, the No. 1 stepping motor that controls the rotation of the Z-axis moving track 4, the No. 2 stepping motor that controls the movement of the Y-axis moving track 5, and the No. 3 stepping motor that controls the movement of the X-axis moving track 6. Cylinder 7 and winding machine head 8; the Y-axis moving track is slidingly connected to the X-axis moving track, and the Y-axis moving track is connected to the Z-axis moving track through a sliding column. The winding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com