Edge folding and shape fixing mechanism for woven bag production assembly line

A production line and woven bag technology, applied in the field of hemming solid mechanism, can solve the problems of high defective rate, slow speed, high manual labor intensity, etc., and achieve the effect of overcoming slow speed and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

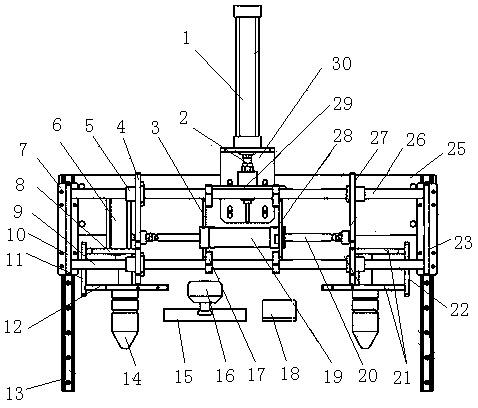

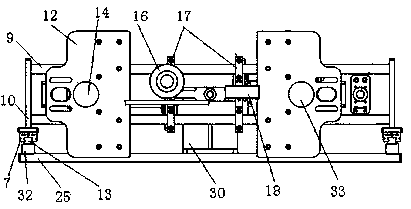

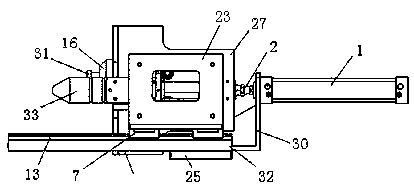

[0014] A folding and fixing mechanism for woven bag production line, including a bracket, a main cylinder 1, a sliding frame, a fixed frame, a woven bag rotating mechanism, a hemming device 18, a high-frequency sealing machine 16, a main cylinder 1, a bag Side device 18, high-frequency sealing machine 16, sliding frame are installed on the bracket, main cylinder 1 cylinder liner is installed on the mounting bracket 30 on the bracket, and the other side of mounting bracket 30 is connected on the bracket pallet 25, the main cylinder 1. The piston end is installed on the connecting plate 29 of the fixed frame; the sliding frame includes a front slide bar 26, a rear slide bar 9, and a support side plate 10, and the two ends of the slide bar are provided with a support side plate 10, and the front slide bar 26 and the rear slide bar 9 1. Vertically fixedly connected with the support side plate 10, the support side plate 10 lower end is provided with a slide block 7, and the slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com