A kind of production method of pneumatic tire and pneumatic tire

A technology for pneumatic tires and production methods, applied to tire parts, with multiple inflatable chambers, with independent inflatable cushions, etc., can solve problems such as inner tube flattening, affecting personnel safety, vehicle rollover, etc., and achieve improvement Strength, improve safety, improve the effect of blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

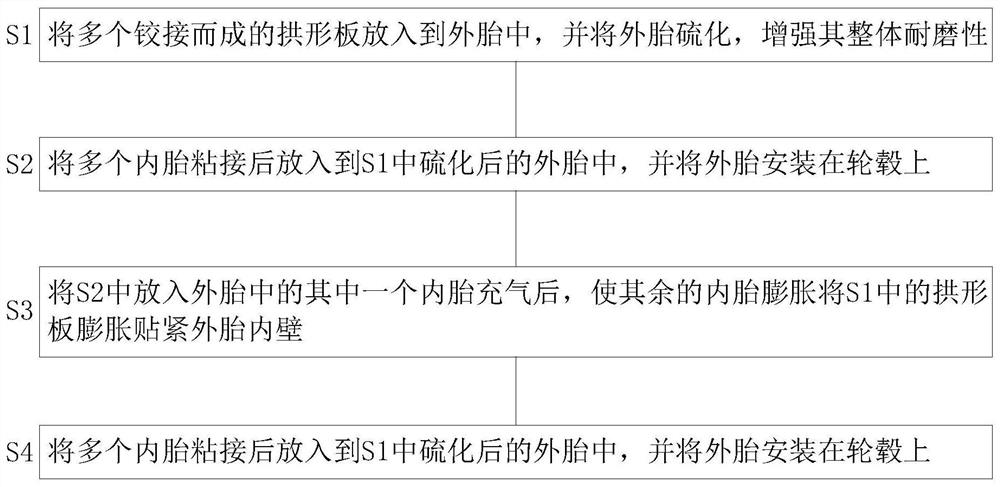

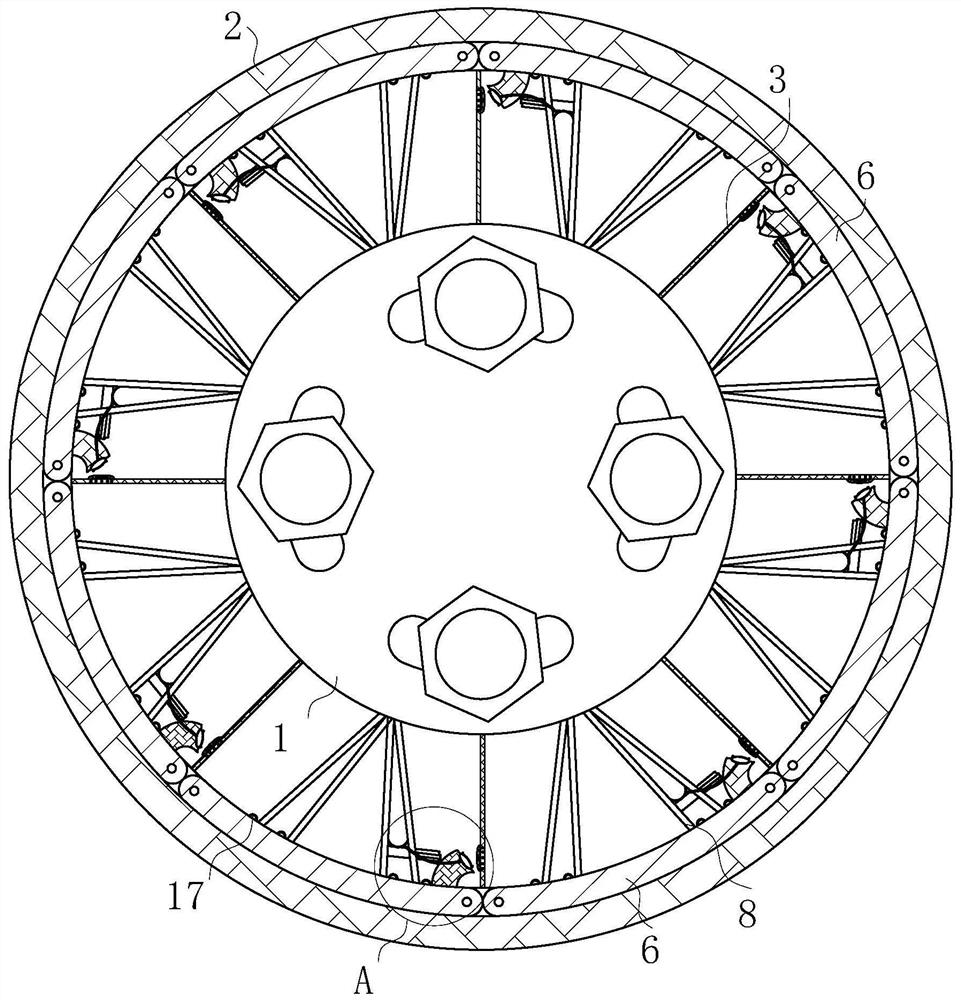

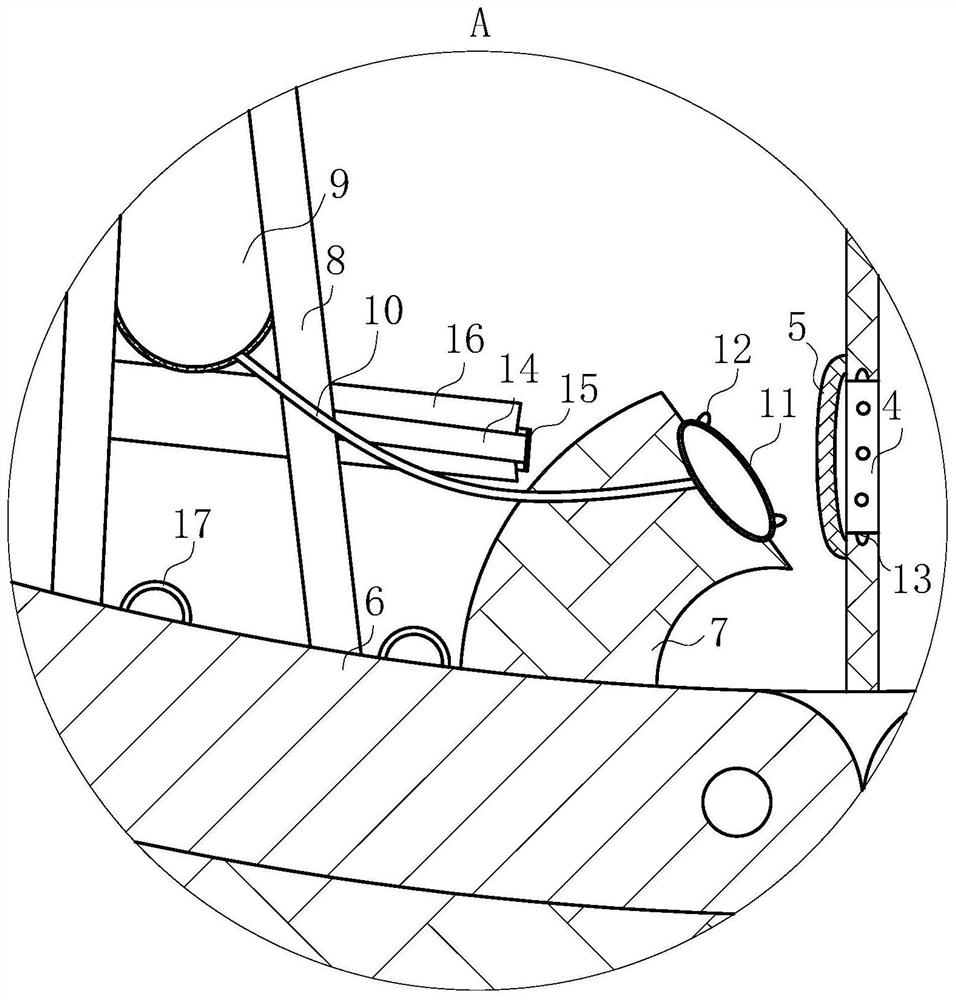

[0028] Such as Figure 1-5 As shown, the production method of a pneumatic tire and the pneumatic tire according to the present invention include a hub 1, a tire 2 is arranged on the outside of the hub 1, and a plurality of tires bonded to each other and surrounded by a ring are arranged inside the tire 2. Inner tubes 3, air filling holes 4 are arranged between the adjacent inner tubes 3, and one end of the air filling holes 4 is provided with a sealing film 5, and the sealing film 5 is set at the end of the air filling holes 4 with the center of the tire as the origin and rotated at a fixed angle part; the inner wall of the tire 2 is provided with an arched plate 6, the arched plate 6 is arched away from the hub 1 after inflation, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com