Mounting structure of decoration side plate and escalator or moving walk

A technology for moving sidewalks and installation structures, applied in escalators, transportation and packaging, etc., can solve the problems of complex procedures, poor quality stability, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

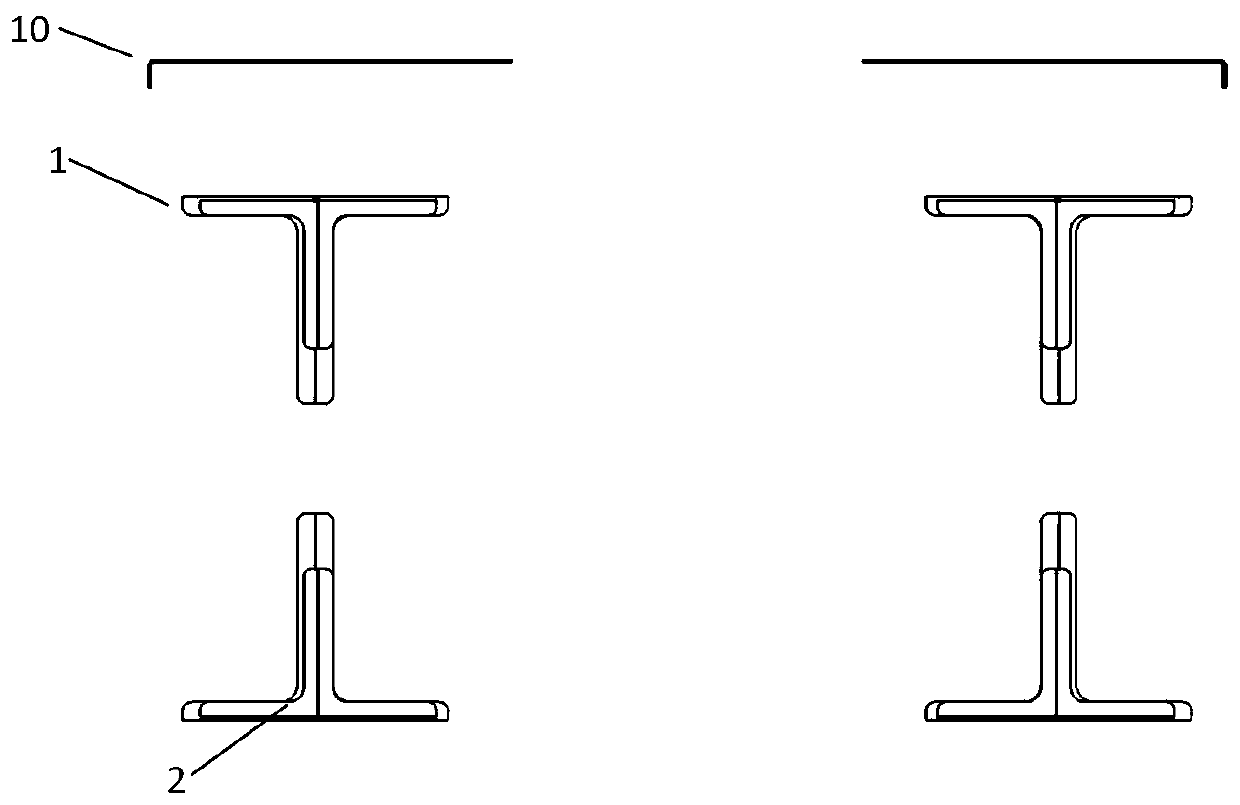

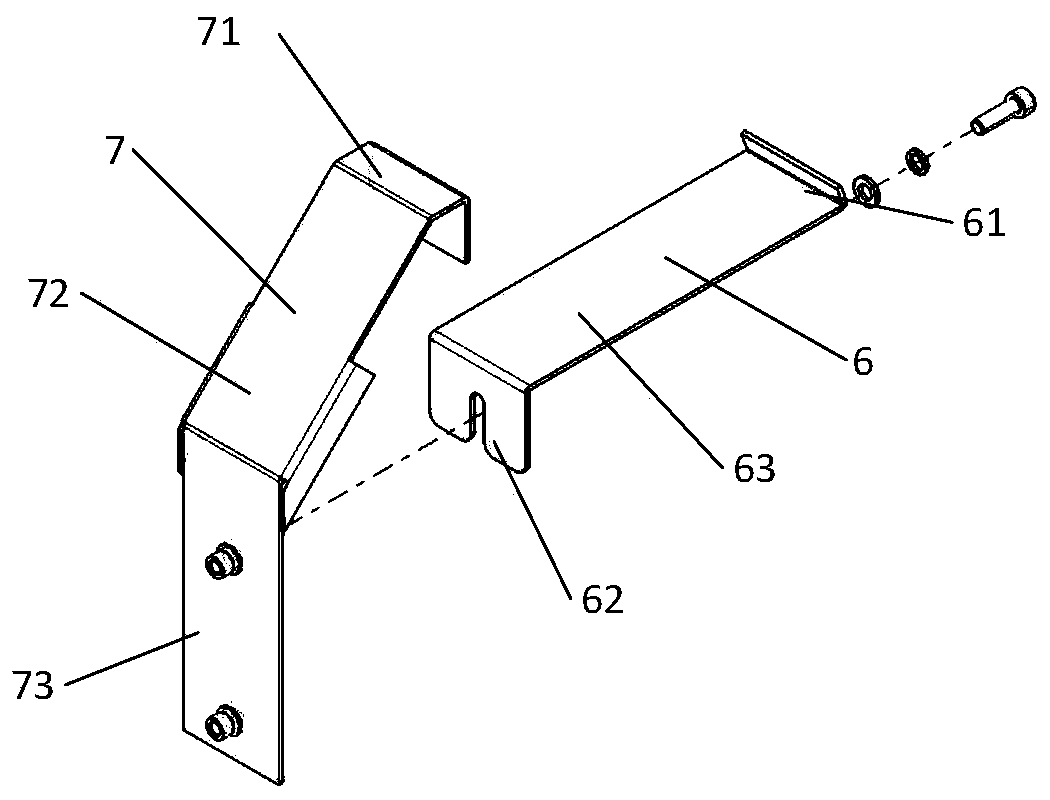

[0087] When the installation structure of the present invention is arranged on the upper and lower main girders of the truss made of double-angle steel composite profiles, such as Figure 1-5 shown, perform the following installation steps:

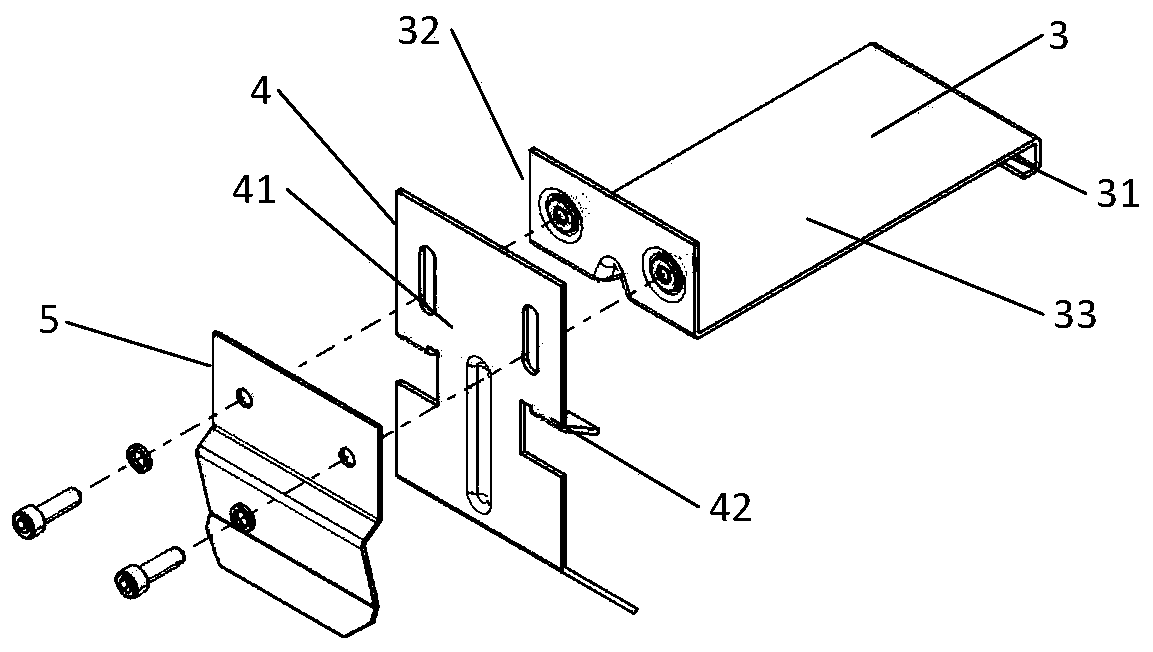

[0088] First, hook the upper main beam top part 3 to the inner edge of the upper main beam 1 of the truss, use bolts to fasten the upper main beam side part 4 and clip part 5 to the upper main beam top part 3, and adjust the upper main beam up and down. The beam side part 4 enables the upper main beam module to be locked on the upper main beam, in this step:

[0089] A folded edge is added to the lower part of the first facade 31, which is used to better clamp itself to the top surface of the upper main beam 1, so that it is not easy to fall off;

[0090] Two rivet nuts are preset on the first datum surface 32, which are used to determine the installation datum of the upper left and right positions of the decorative side plate;

[0091]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com