Telescopic hanging lamp embedded assembly

A telescopic and hanging nail technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of prefabricated wall panel collapse, limited space for installation of lifting fixtures, affecting production efficiency and product quality, etc., to improve strength, Increased safety performance, convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

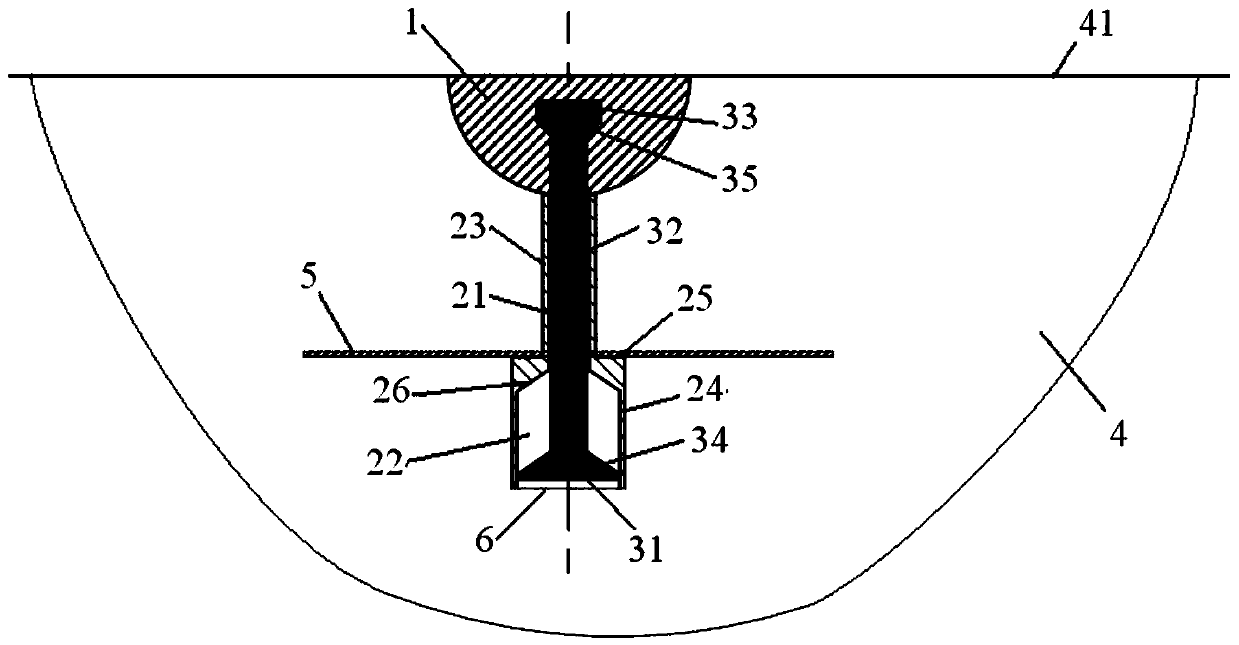

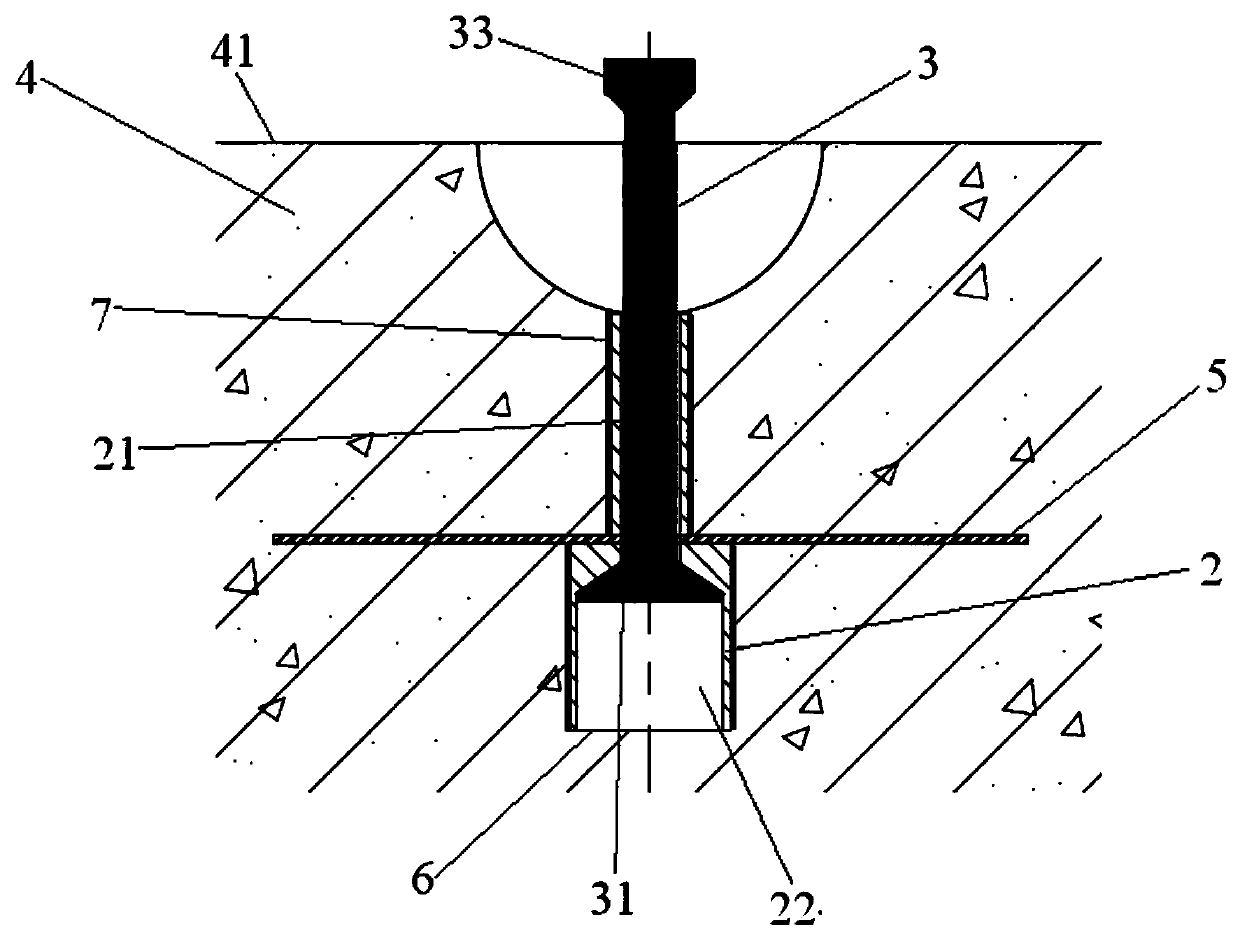

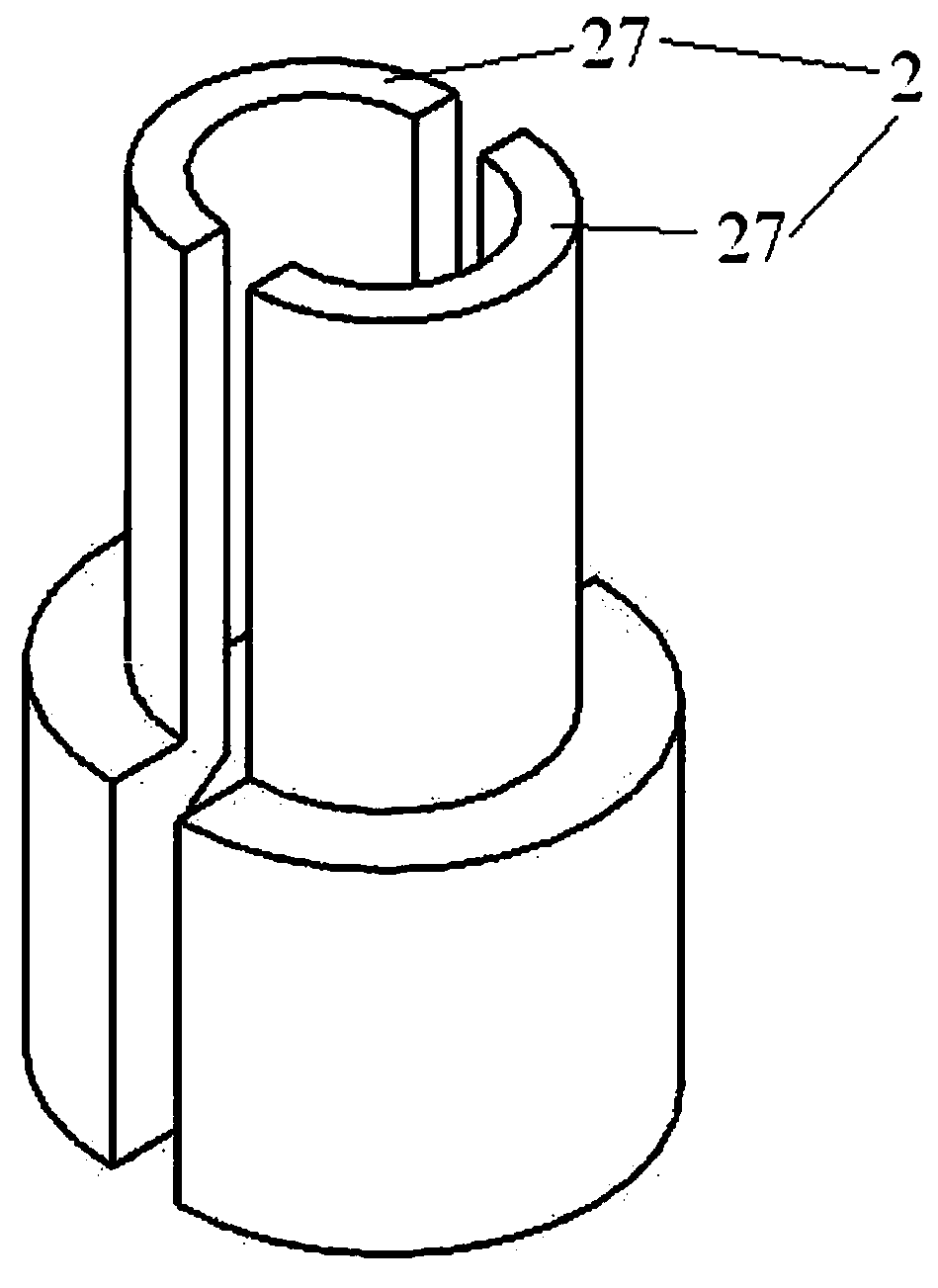

[0028] see Figure 1 ~ Figure 3 A telescopic hanging nail pre-embedded assembly, including a rubber mandrel 1 for pre-embedding in the wall panel 4 when pouring the wall panel, a steel sleeve 2 and a hanging nail 3, the hanging nail The nail includes a tail 31 near the center of the wall, a central neck 32 and a head 33 near the side wall of the wallboard. The radial dimensions of the tail and the head of the hanging nail are larger than the radial dimension of the neck. A first shoulder 34 is provided at the junction of the tail and the neck of the hanger, a second shoulder 35 is provided at the junction of the head and the neck of the hanger, and the head of the hanger and the part of the neck near the head are formed by the The mandrel is wrapped and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com