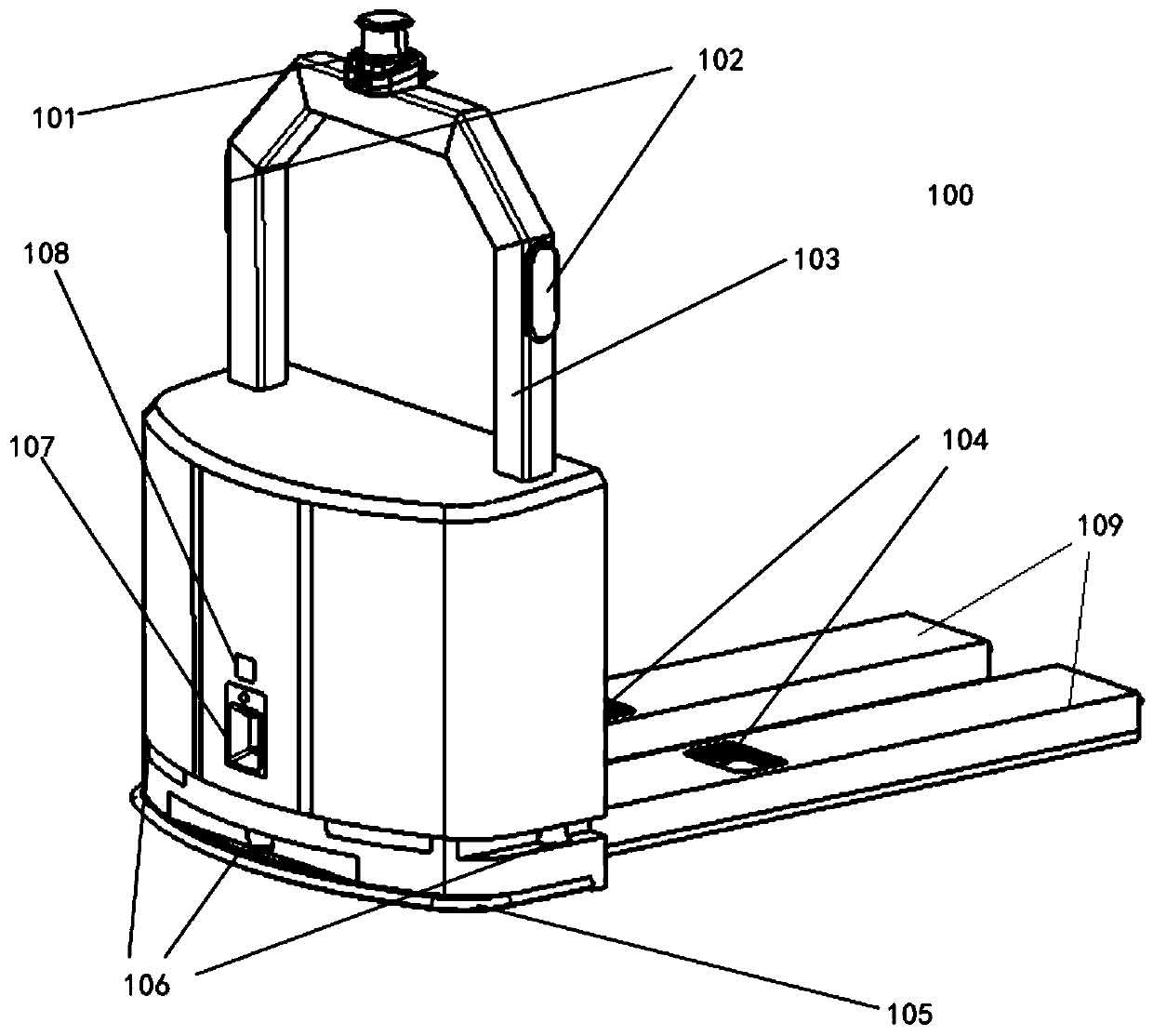

Carrying robot control method and cargo carrying system

A technology of handling robots and control methods, which is applied in the field of goods handling systems and control of handling robots, can solve the problems of occupying human resources, giving efficiency, increasing warehouse operating costs, etc., and achieves the effect of strong scalability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

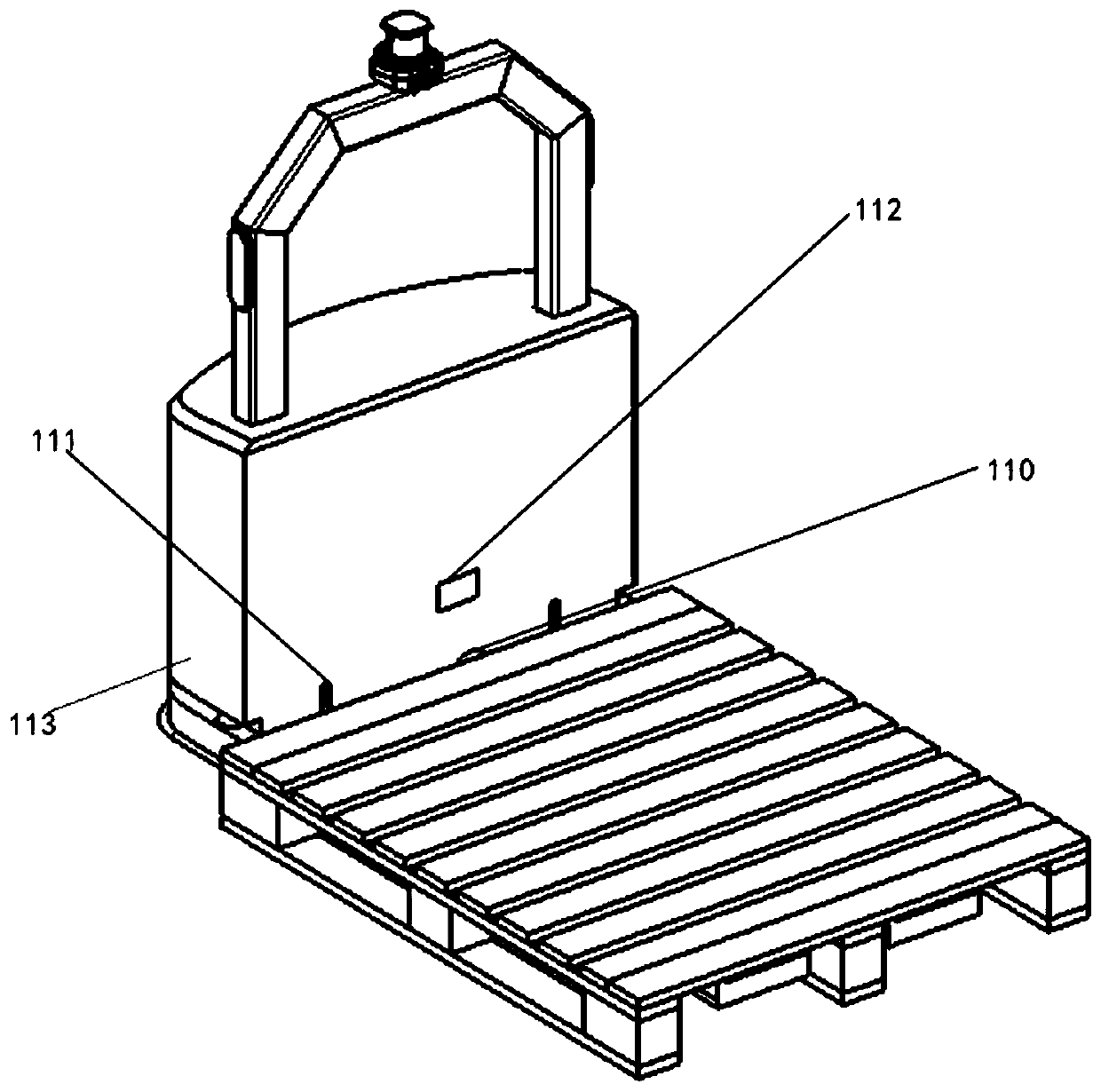

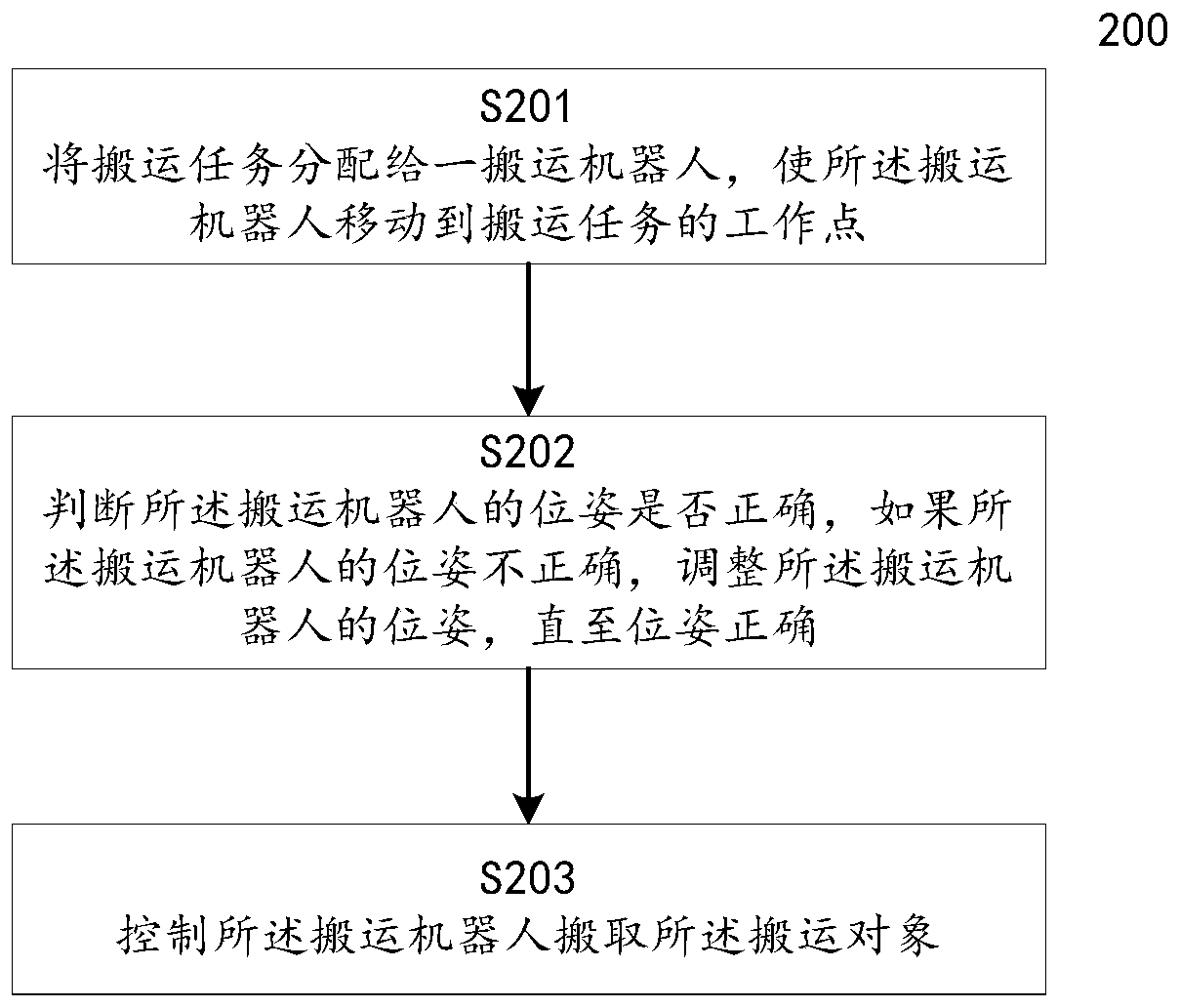

[0067] 1. The dispatching system receives the handling demand;

[0068] 2. The dispatching system assigns the intelligent cow A to the starting position aa to pick up the pallet;

[0069] 3. Intelligently, Niu A carries the pallet and moves to the position bb next to the shelf;

[0070] 4. Intelligently put down the tray, and follow the dispatching system order to perform other tasks;

[0071] 5. Intelligent stacking forklift B lifts up pallets and stacks them on high-rise shelves;

application example 2

[0073] 1. The dispatching system receives the handling demand;

[0074] 2. The dispatching system assigns the intelligent cow A to the starting position aa to pick up the pallet;

[0075] 3. Intelligently, cow A carries the tray and moves to the vicinity of workstation bb;

[0076] 4. The submerged handling robot B carries the shelf and moves to the vicinity of the workstation bb;

[0077] 5. According to the task information, the robotic arm C in the workstation grabs the corresponding quantity of goods from the pallet and places them on the corresponding position on the shelf;

[0078] 6. According to the arrangement of the dispatching system, intelligent ground cow A leaves the workstation with the tray to the next target position cc;

[0079] Advantages of embodiments of the present invention include:

[0080] Low cost, the entire pallet handling process is fully automated without human manipulation. Compared with the traditional model, each robot can save one person's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com