Low-temperature multi-effect seawater desalination device novel spray system

A spray system and low-temperature technology, applied in the field of spray systems, can solve the problems of reduced contact area, reduced heat transfer efficiency, reduced water production ratio, etc., and achieve the effects of smooth over-regulation, increased production efficiency, and delayed corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

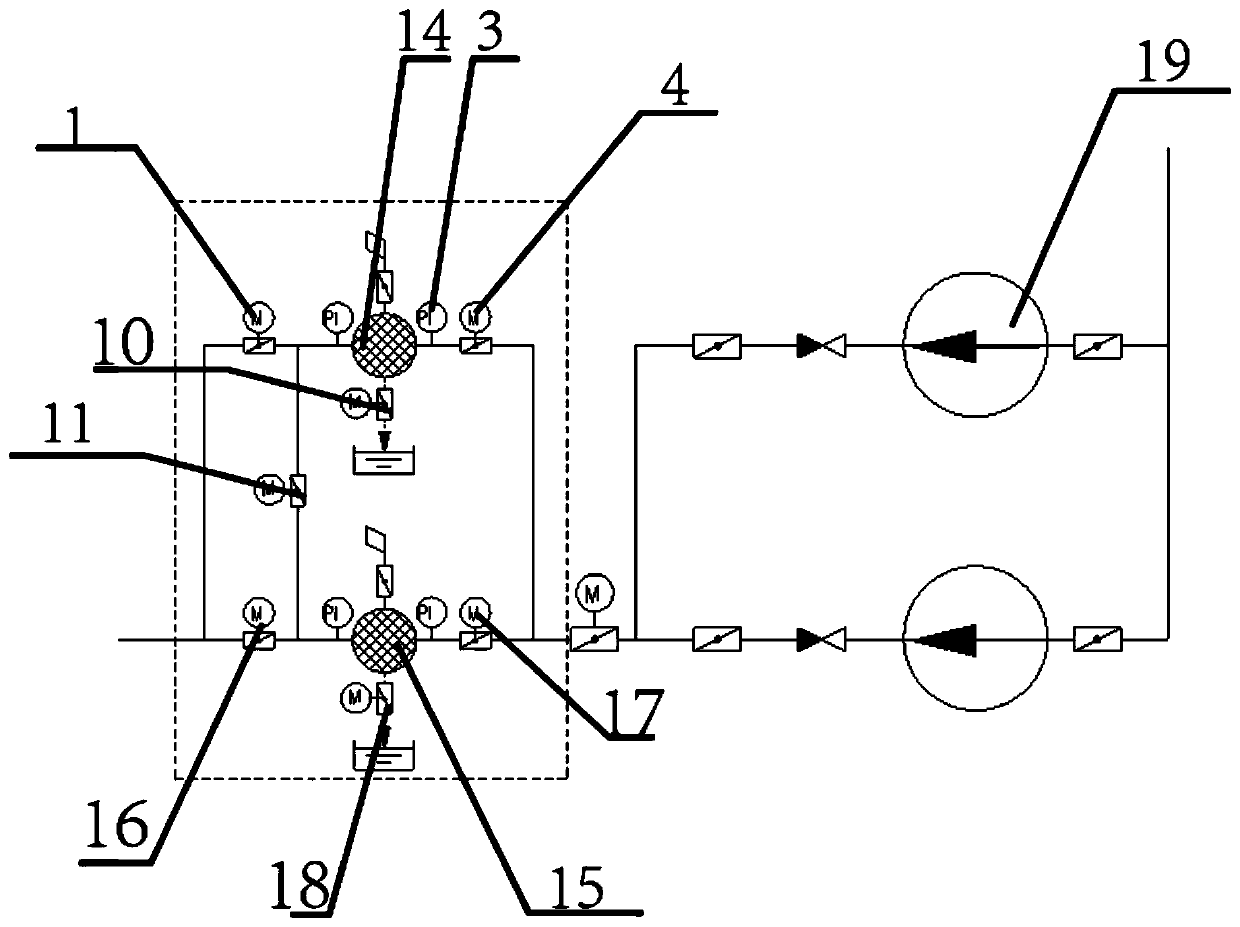

[0061] Such as Figure 6 As shown, the connection electric door 11 between the first filter 14 and the second filter 15 is closed, and the first filter 14 and the second filter 15 operate simultaneously. The cold sources enter the inlets of the first filter 14 and the second filter 15 respectively, and flow out from the outlets of the first filter 14 and the second filter 15 . In this way the first filter 14 and the second filter 15 operate simultaneously.

Embodiment 2

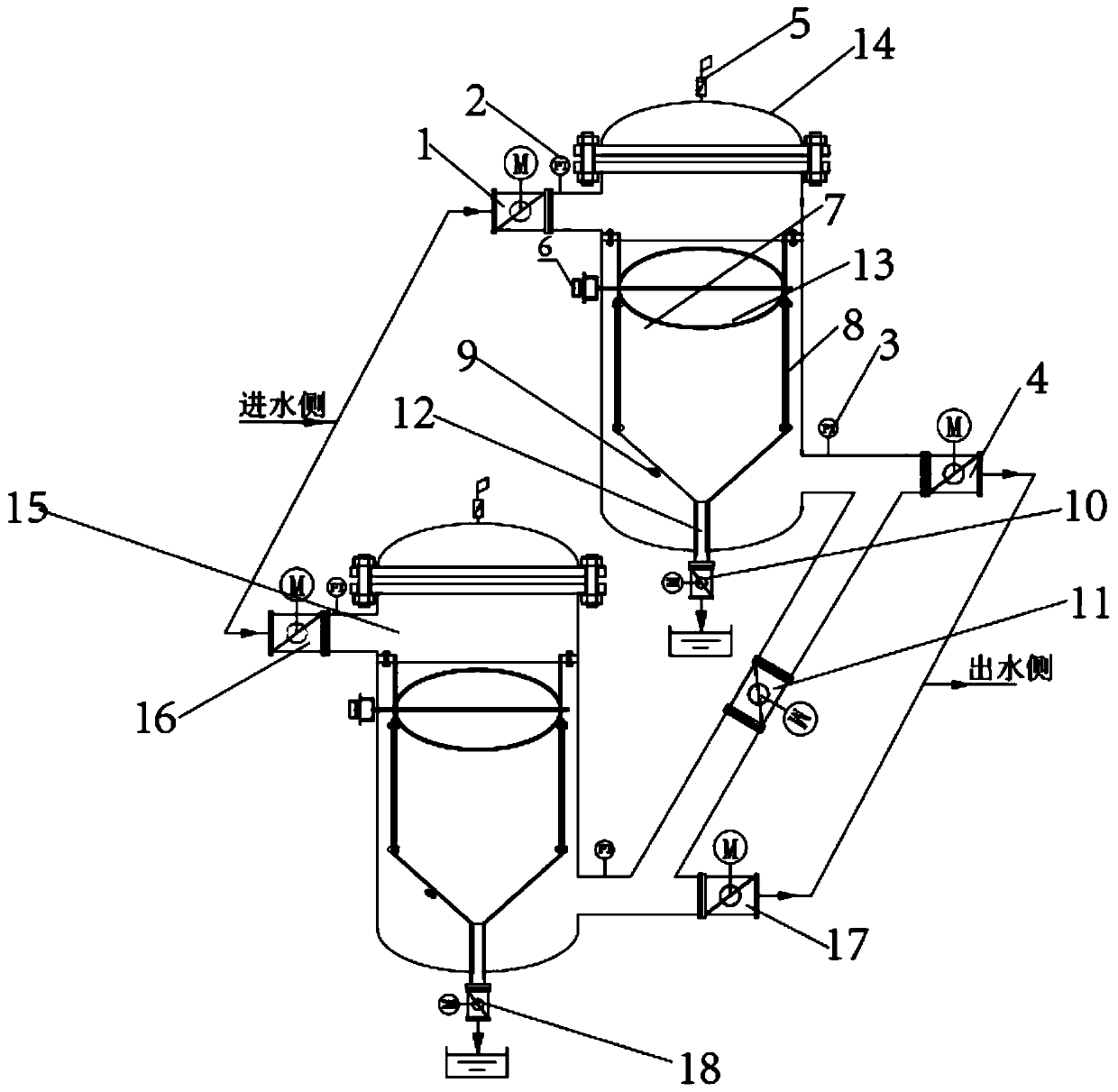

[0063] Such as Figure 7 As shown, open the connection electric door 11 between the first filter 14 and the second filter 15, close the second inlet electric door 16 and the second outlet electric door 17 of the second filter 15, and open the second sewage electric door 18. At this time, the first filter 14 operates normally, and at the same time, the first filter 14 provides a clean water source for the second filter 15 for cleaning. The cleaning water source passes through the contact electric door 11, enters from the outlet of the second filter 15, enters the inside of the filter cartridge 7 from the outside of the filter cartridge 7 for backwashing, washes away the impurities deposited on the inside of the filter cartridge 7, and backwashes the sewage from the bottom of the filter cartridge 7. The second sewage pipe discharges. This method is used when the load of the seawater desalination equipment is relatively low. At this time, the first filter 14 is in the working s...

Embodiment 3

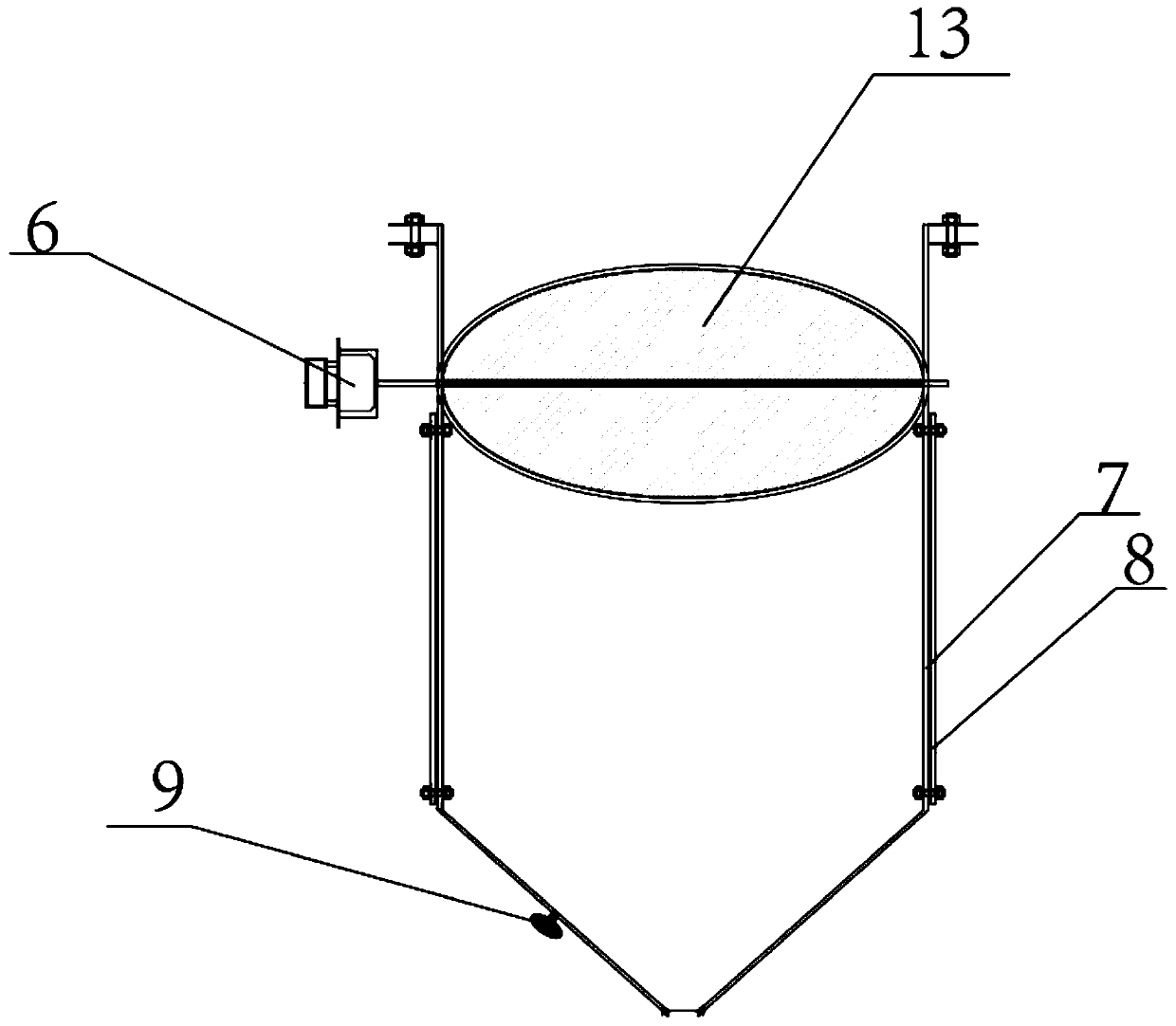

[0065] If the load of seawater desalination equipment is high, but at the same time the filter needs to be cleaned, this cleaning method should be used: Figure 8 As shown, now the first filter 14 is in working condition, and the second filter 15 is in the internal cleaning state, close the connection electric door 11 between the first filter 14 and the second filter 15; close the second filter 15 The pneumatic shut-off valve 6, so that the shut-off valve valve plate 13 is in a closed state; open the second sewage discharge electric door 18; at this time, in the second filter 15, the cold source flows out from the side wall on the upper side of the filter cartridge 7 and enters The gap between the outside of the filter cartridge 7 and the filter housing flows in from the outside of the filter cartridge 7 to backwash the lower filter cartridge 7 of the second pneumatic shut-off valve 6, and the backwash sewage flows from the second sewage pipe at the bottom of the filter cartrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com