Steel slag concrete

A technology of steel slag concrete and steel slag, applied in the field of concrete, can solve rare problems, and achieve the effects of improving greenness, obvious economic benefits, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

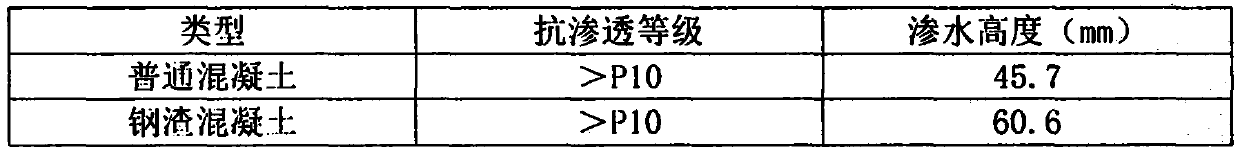

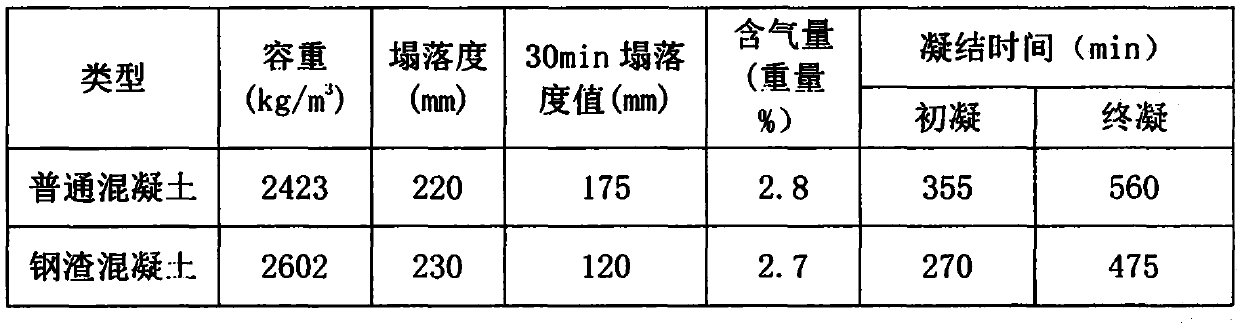

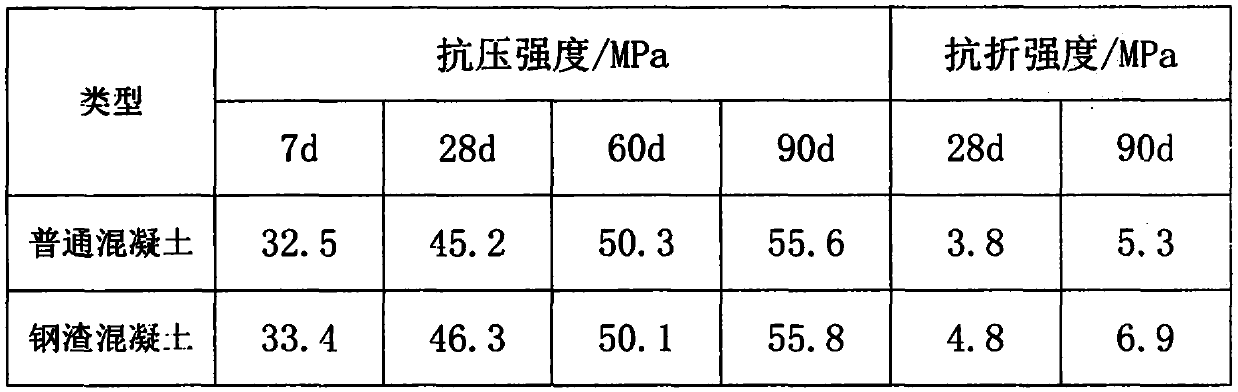

[0008] In order to better compare the difference in mechanical properties and durability between steel slag concrete and ordinary concrete, comparative experiments were carried out with reference to the mix ratio of ordinary concrete.

[0009] The preparation steps of steel slag concrete mix ratio of the present invention are:

[0010] 1. First of all, determine the various raw materials for concrete preparation. Since steel slag is used as the coarse aggregate, steel slag is easy to absorb water and burst, which is not conducive to the stability of concrete volume.

[0011] For the above-mentioned various concrete raw materials, select the preferred supplier company, select at least three supply companies for each material, conduct laboratory sampling and testing, perform testing and comparison analysis on performance indicators and chemical components, and select the most suitable material supplier: choose Wulashan cement for cement, Fly ash is selected Huadian fly ash and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com