A kind of protective rubber composition for tire pads and its preparation method

A technology of composition and pad, which is applied in the field of rubber tires, can solve problems affecting the use of tires or pads, shorten the service life of pads, and wear of metal gaskets, so as to reduce labor intensity, prolong service life, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

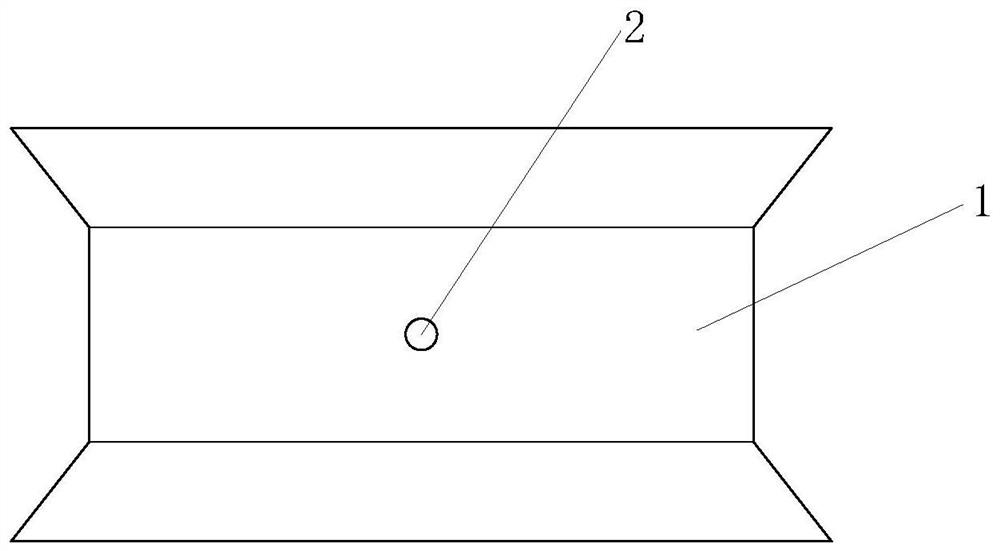

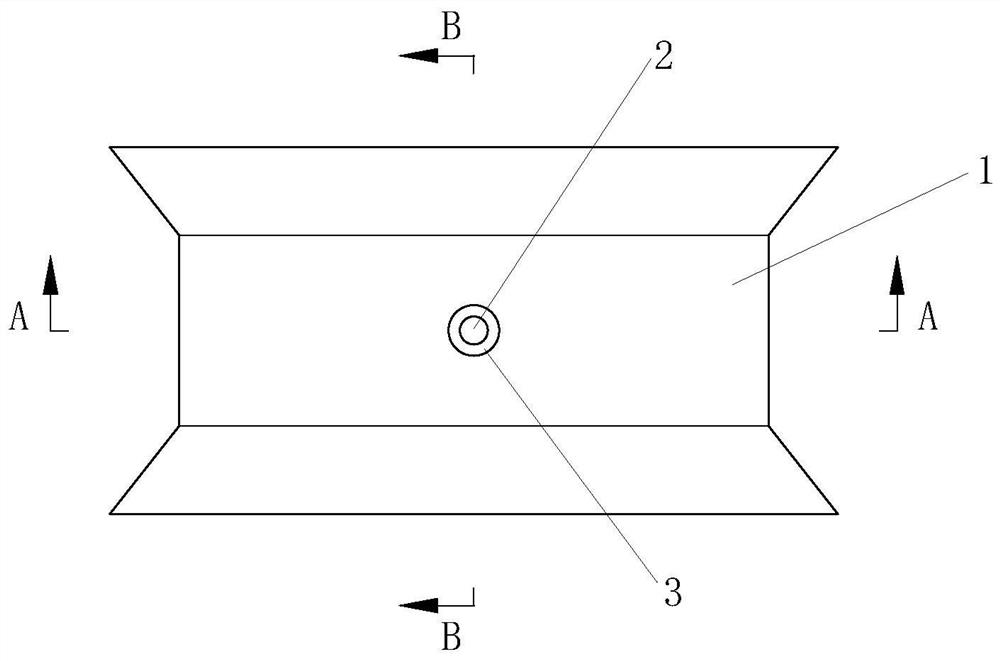

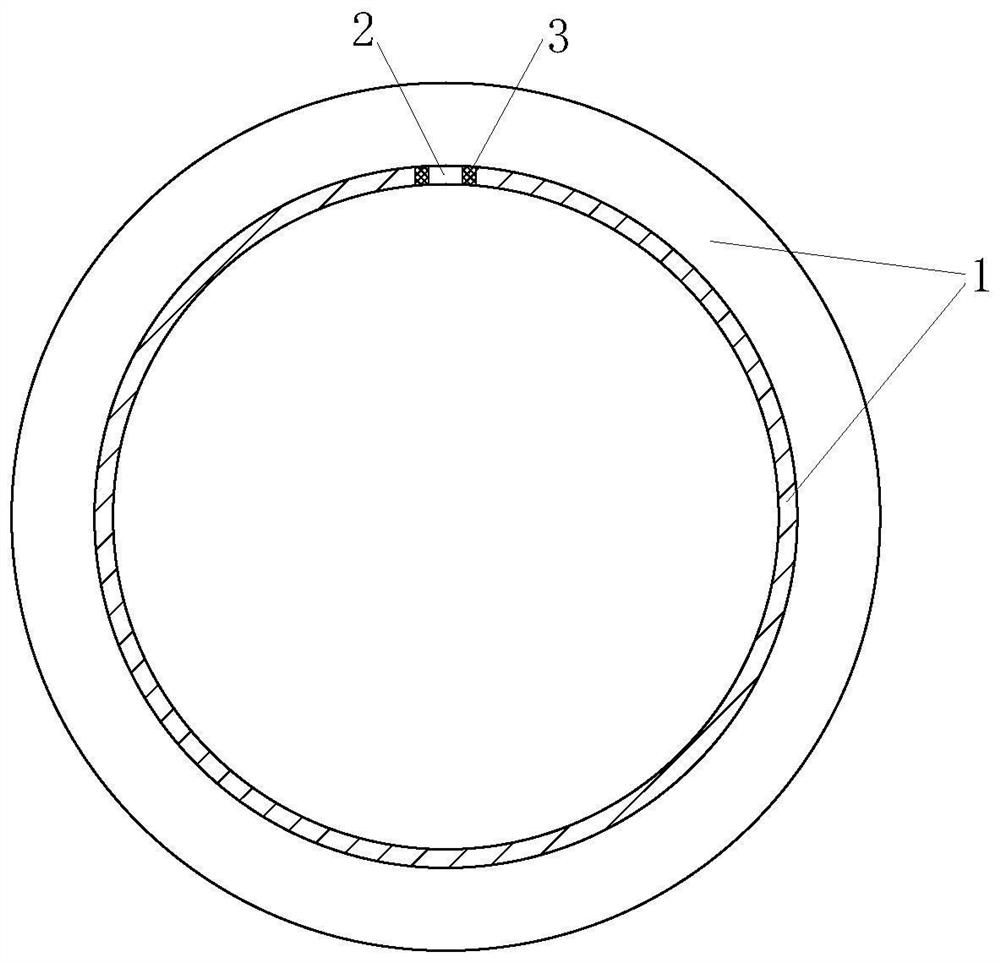

Image

Examples

Embodiment 1

[0028] Embodiment 1, embodiment 2, embodiment 3, embodiment 4, embodiment 5 described a kind of formula of tire pad bead mouth protection rubber composition is as table 1: (the unit of each raw material content in table 1 is: weight part) Table 1: Adhesive adhesive layer formula for heat-resistant polyester canvas conveyor belt

[0029] Recipe Components Example 1 Example 2 Example 3 Example 4 Example 5 Isoprene rubber 70 80 85 90 95 SBR1507 rubber 30 20 15 10 5 Nano Zinc Oxide 2.5 3 3.5 4 5 stearic acid 1.5 2.5 2 3 1.5 Dispersant HT 1.5 2 1.5 2.5 3 Silica 20 15 10 18 5 N351 carbon black 40 70 60 57 55 Antiaging agent DTPD 1.5 2 1.8 3 1 Antiaging agent IPPD 1.5 1 1.2 1 3 Silane coupling agent NXT 2 1.5 1 1.8 1 A-250 resin 1 1.5 2 2.5 3 Insoluble sulfur OT7020 3 4 5 4 5 Accelerator TBSI 1 0.8 1 1 1.5 Vulcanizing agent DTDM 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com