Washing machine

A washing machine and detergent box technology, applied in the field of washing machines, can solve problems such as poor product experience, clothing pollution, and mold growth, and achieve the effects of improving satisfaction, drying space, and eliminating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

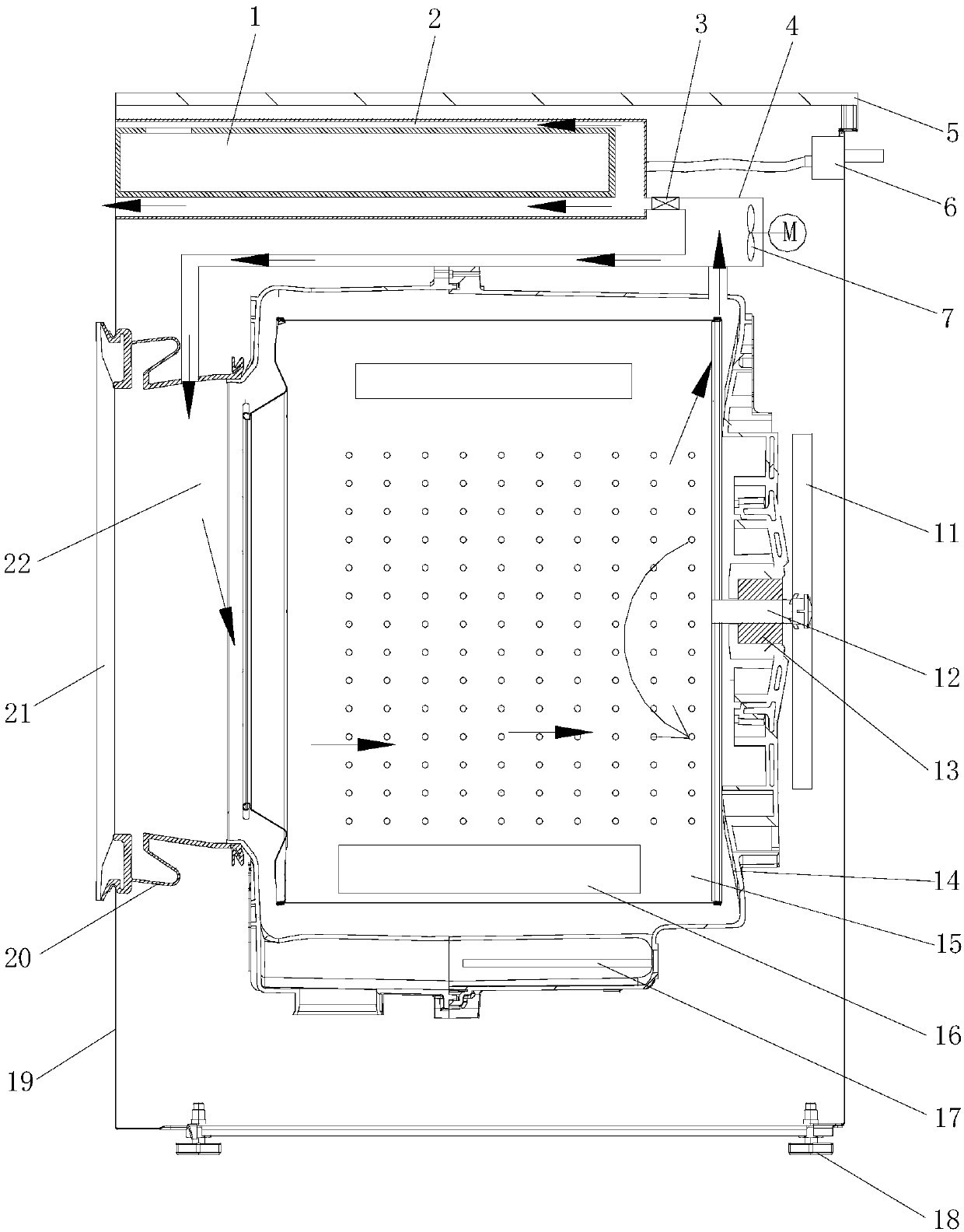

[0028] This embodiment provides a washing machine, which may be a drum type washing machine or a pulsator type washing machine, and this embodiment is preferably described by taking the drum type washing machine as an example. Such as figure 1 As shown, the washing machine includes a casing 19, an outer cylinder 14 is installed in the casing 19, an inner cylinder 15 is installed in the outer cylinder 14, and a lifting rib 16 is provided at the bottom of the inner cylinder 15; the inner cylinder 15 is connected to the motor 11 through a transmission shaft 12 A bearing 13 is installed on the drive shaft 12, and the inner cylinder 15 is driven to rotate by the operation of the motor 11, thereby rolling and washing the clothes. Doors and windows 21 are also installed on the casing 19, and the doors and windows 21 are sealed and connected with the washing machine casing 19 through the sealing window gasket 20. The upper part of the washing machine is located above the outer cylind...

Embodiment 2

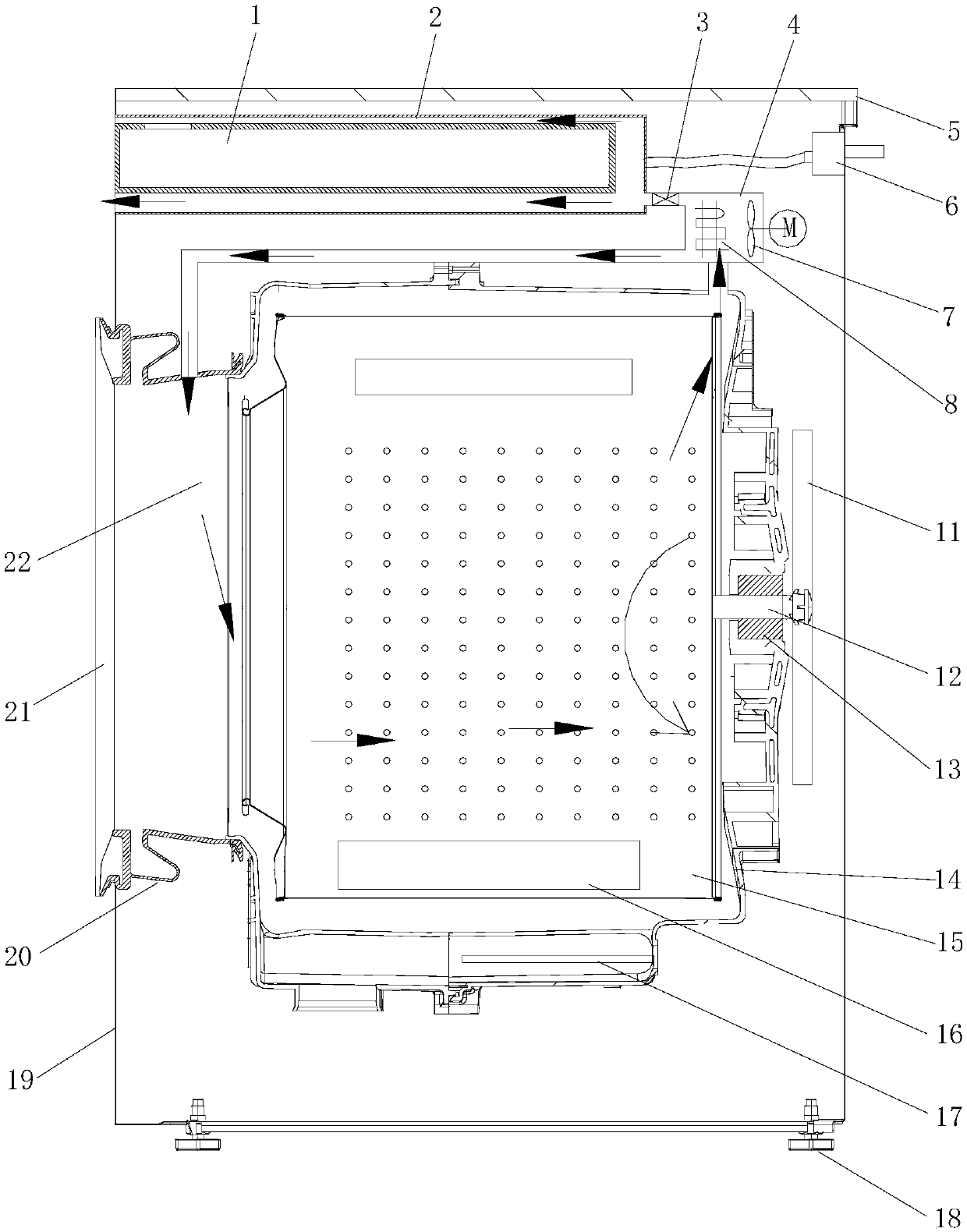

[0035] Such as figure 2 As shown, the present embodiment provides another washing machine, and the difference between the washing machine and the washing machine in Embodiment 1 is:

[0036]The washing machine in this embodiment is an all-in-one washing and drying machine, and the drying air duct is a circulating air duct 22 provided in the all-in-one washing and drying machine. One end of the detergent box chamber 2 is connected to the circulating air duct 22 through the connecting air duct 4, and the other end is connected to the circulating air duct 22. The outside atmosphere is connected; meanwhile, the heating device in this embodiment is the second heater 8 used for drying clothes in the washer-dryer. Specifically, the second heater 8 is arranged at one end of the connecting air duct 4 close to the detergent box chamber 2, so that the airflow to enter the detergent box chamber 2 can be heated more efficiently to avoid waste of heat. Improve drying efficiency. Here, th...

Embodiment 3

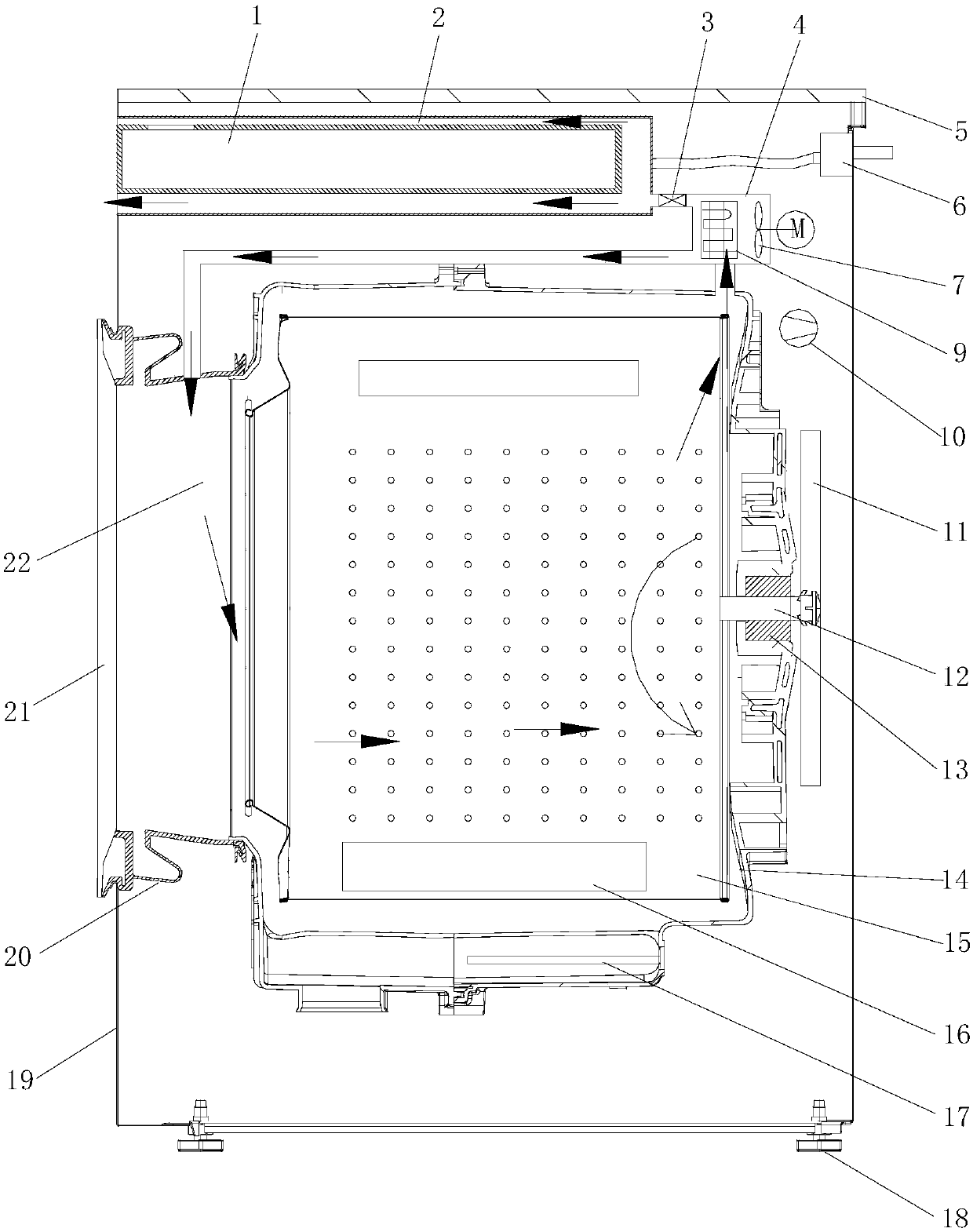

[0039] Such as image 3 As shown, the present embodiment provides yet another washing machine, and the difference between this washing machine and the washing machine in Embodiment 2 is that:

[0040] The washing machine in this embodiment is a heat pump washing and drying machine, and its heating device is the condenser 9 of the heat source heat pump system. Specifically, the condenser 9 is arranged at one end of the connecting air duct 4 close to the detergent box chamber 2, so that the airflow to enter the detergent box chamber 2 can be heated more efficiently, avoiding the waste of heat, and improving the dryness. efficiency. The heat pump system of the washing machine can ingeniously recycle the heat generated during the drying process without heating by heating pipes, thereby reducing energy waste; at the same time, since there is no heating by heating pipes, the airflow temperature is usually around 60 degrees, which will not cause high temperature damage. Other struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com