Integrated prefabricated pumping station for automatic separation and lifting of sewage and sewage

An automatic separation and sewage technology, which is applied in drainage structures, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of not being able to automatically separate and lift sewage and dirt, and achieve automatic cleaning of solid-liquid separation devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

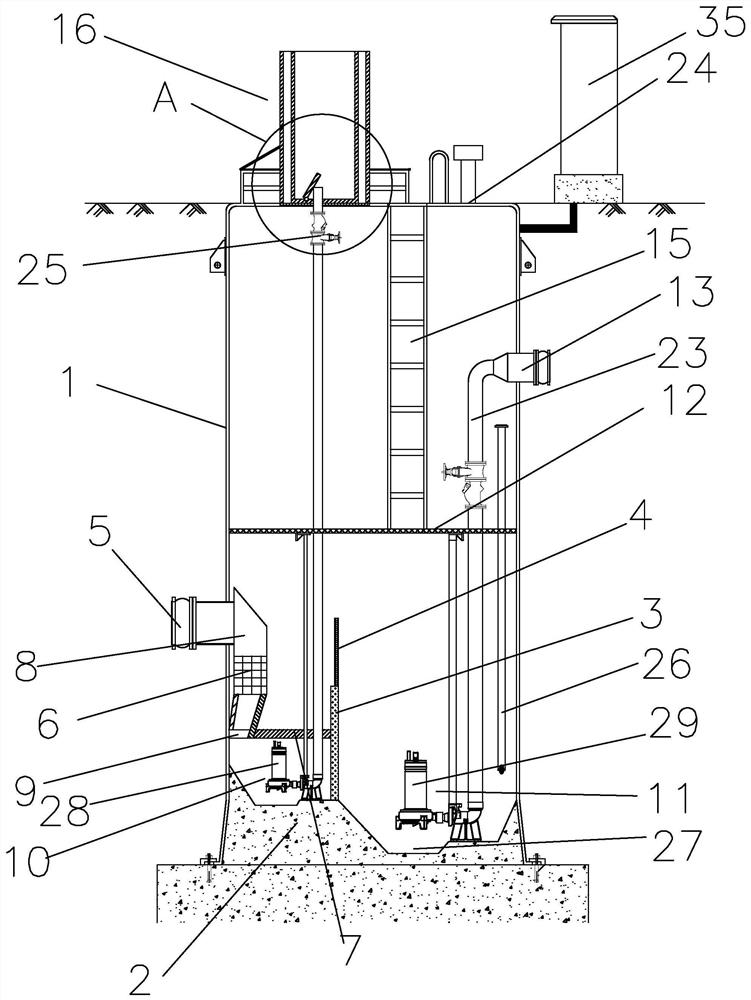

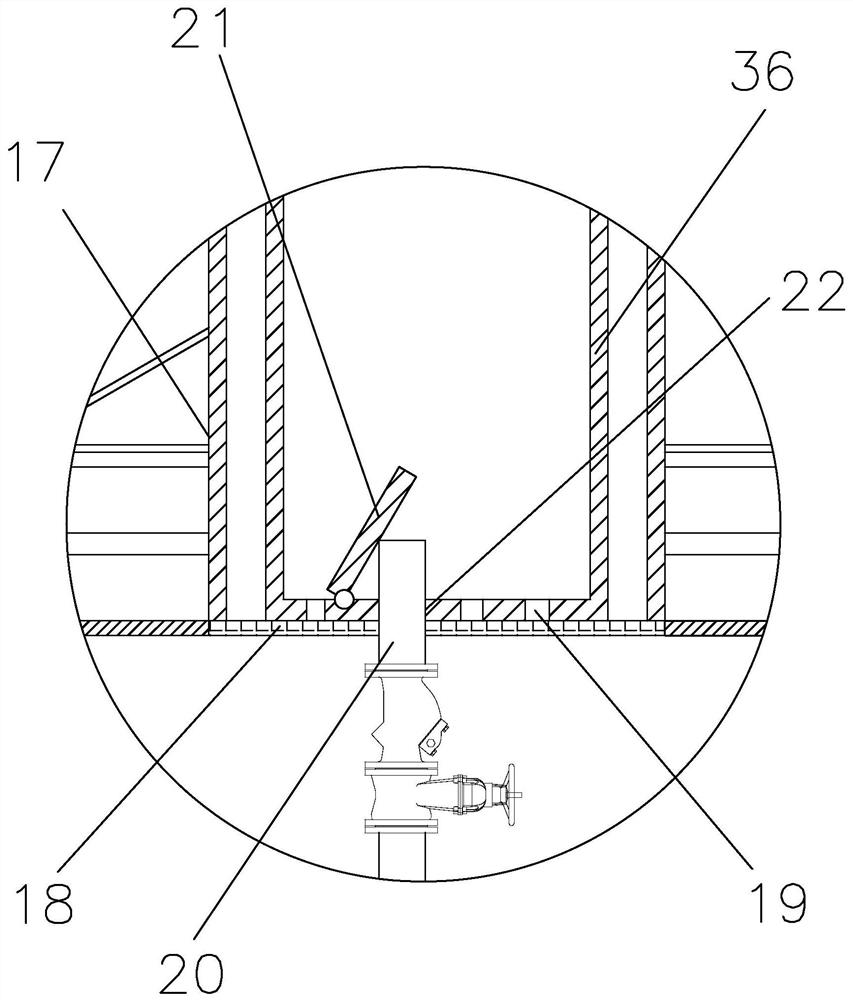

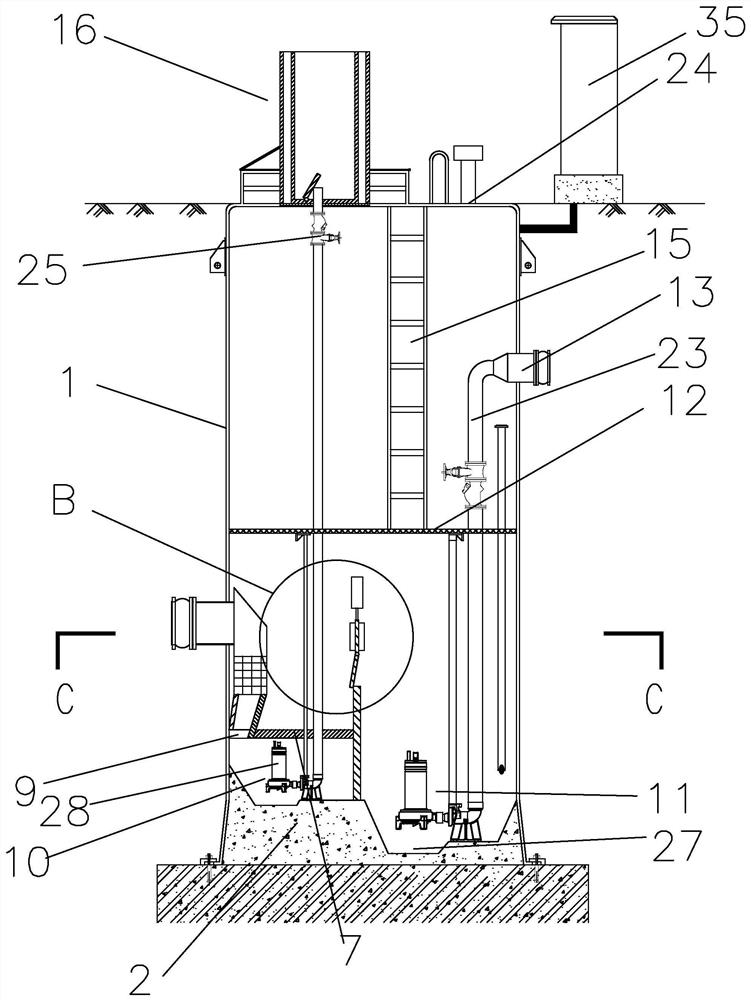

[0024] figure 1 and figure 2It is an integrated prefabricated pumping station for automatic separation and lifting of sewage and sewage, including a cylinder body 1, which is made of high-strength fiberglass reinforced plastic (GRP) material, and the cylinder body 1 is a cylindrical structure. The ground is level, the bottom of the cylinder 1 is fixed on the foundation 2 by bolts, the inner bottom of the cylinder 1 is provided with a base 2, the base 2 is made of concrete, and a vertical partition 3 is provided on the base 2. The opposite sides of the plate 3 are affixed to the inner wall of the cylinder 1, and the lower side of the partition 3 is affixed to the base 2. The space at the bottom of the inner side of the cylinder 1 is divided into two areas by the partition 3, and one area is the muddy water area. , the other area is the clear water area, a solid-liquid separation device is provided above the partition 3, the solid-liquid separation device is a solid-liquid sep...

Embodiment 2

[0028] Such as Figure 3 to Figure 6 As shown, the general situation of this embodiment is the same as that of Embodiment 1, the difference is that the cylinder body 1 is a cuboid structure, and the solid-liquid separation device includes a sliding solid-liquid separation overflow partition 31 and a rotating solid-liquid separation overflow partition Plate 32, the sliding solid-liquid separation overflow partition 31 is vertically placed, and the sliding solid-liquid separation overflow partition 31 is located above the rotating solid-liquid separation overflow partition 32, and the sliding solid-liquid separation overflow partition 31 is connected to the partition The plates 3 are on the same plane, and the inner side wall of the cylinder body 1 is provided with a chute 30, and the cylinder body 1 is fixedly connected with two vertically placed convex strips 34 at the corresponding positions of the chute 30, and the convex strips 34 are gap-fitted to form the Referring to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com