All-round small integrated garbage processing machine

An integrated garbage disposal technology, which is applied in the field of all-round small integrated garbage processors, can solve the problems of high transportation costs, achieve the effects of saving material investment, reasonable arrangement, and eliminating system wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

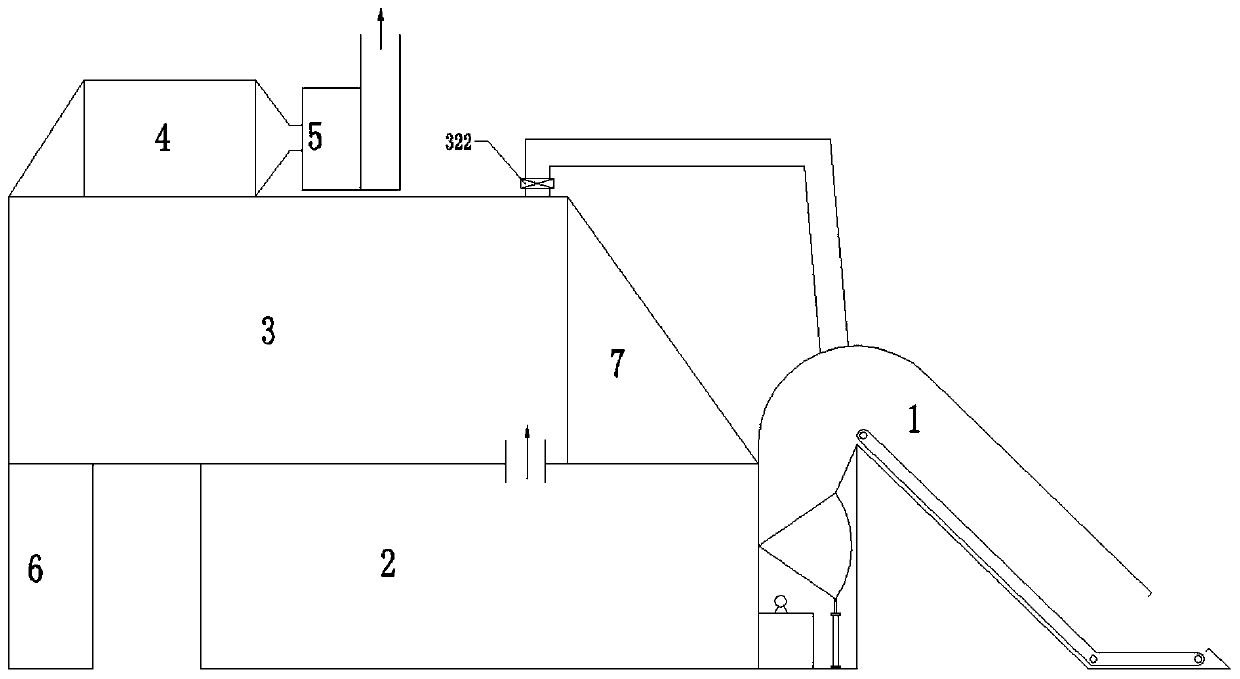

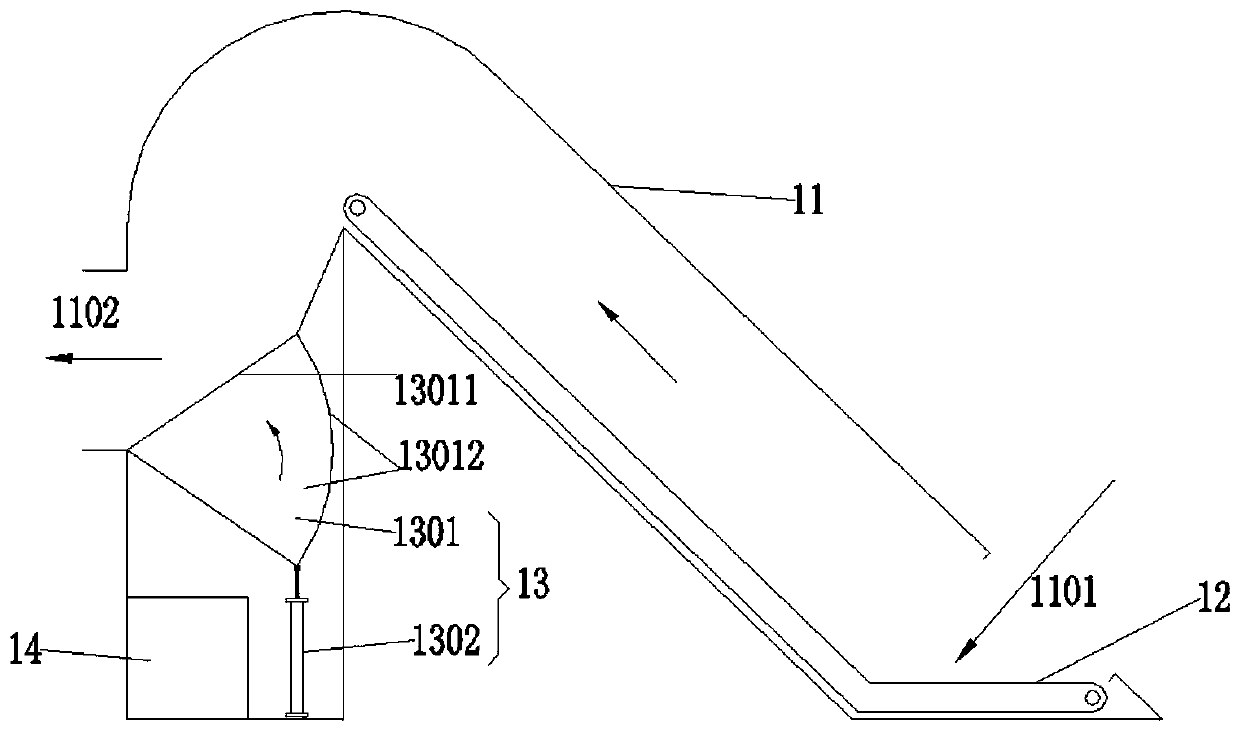

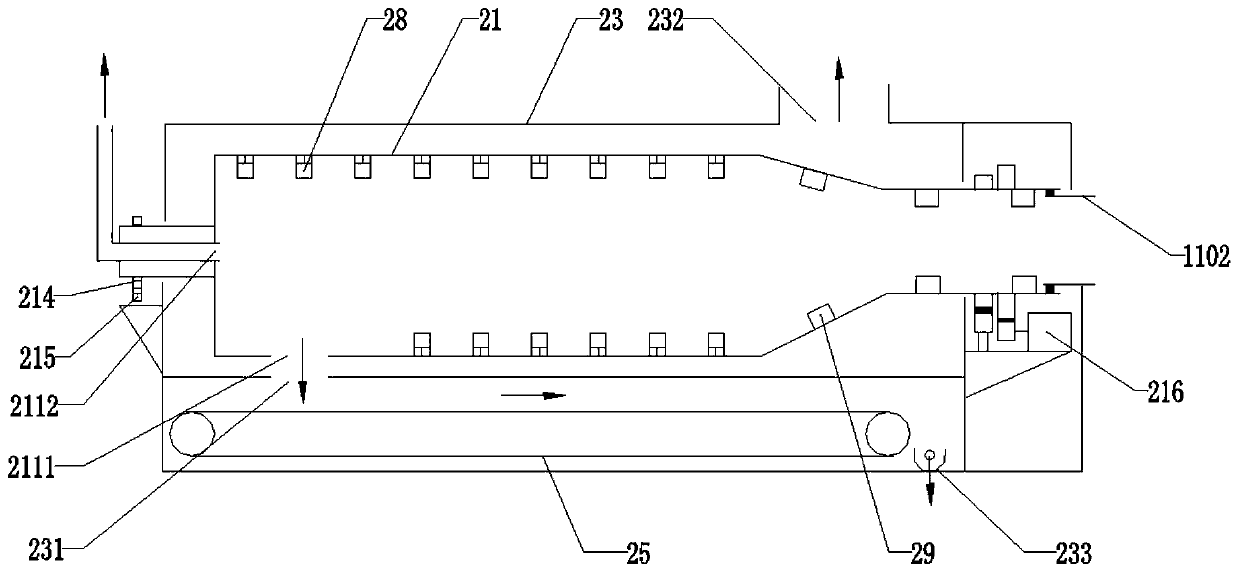

[0048] Such as Figure 1-Figure 13 As shown, this embodiment provides an all-round small-scale integrated garbage disposal machine, which includes a feeding device 1, a box-type pyrolysis gasifier 2, a flue gas treatment box 3, an activated carbon adsorption box 4, and a smoke exhaust fan 5 connected in sequence. The box-type pyrolysis gasifier 2, the flue gas treatment box 3 and the activated carbon adsorption box 4 are arranged in sequence from bottom to top, and the feeding device 1 is arranged in the box-type pyrolysis gasifier 2 side.

[0049] Specifically, the activated carbon adsorption box 4 is a box with activated carbon inside.

[0050] As a further solution of this embodiment, the top wall of the box-type pyrolysis gasifier 2 has a flue gas outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com