Tri-axial leveling device and application thereof

A technology of leveling device and platform, applied in the direction of measuring device, instrument, supporting machine, etc., can solve the problems of unfriendly operation, large randomness and system error, and the inability of liquid bubble to accurately respond to the change of the inclination angle of the upper surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

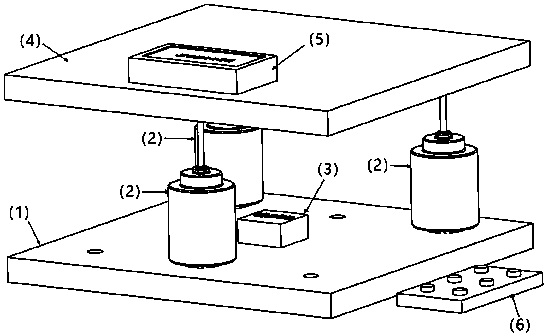

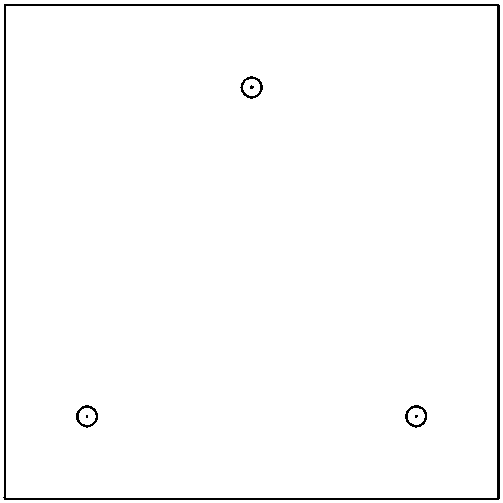

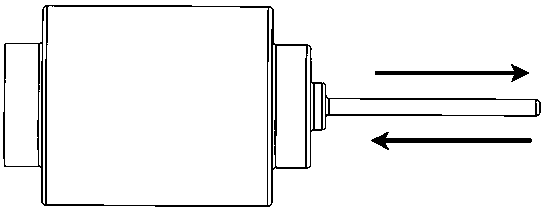

[0010] The base is made of 304 stainless steel with a thickness of not less than 5mm, and three holes are opened. The size of the holes matches the axial displacement motor for installing the axial displacement motor. The three holes are arranged in an isosceles triangle, with the bottom side 100mm long and the bottom side high 100mm. Install the axial displacement motor, and ensure that the displacement shaft of the axial displacement motor is vertical to the base. The platform is made of PEEK plate with a thickness of 10mm. The upper surface is ground and polished, and the surface roughness is better than 0.1mm. Three tapered holes are opened on the lower surface of the PEEK plate. The distribution of the tapered holes is the same as that of the base, and the size of the holes is larger than the axis. 4 times the diameter of the displacement shaft to the displacement motor, and the depth is not less than 3mm. Place the two-axis inclination sensor on the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com