Automatic induction type multi-angle cutting device for aluminum profile production

An automatic induction, cutting device technology, applied in positioning devices, feeding devices, large fixed members, etc., can solve the problems of low cutting accuracy, low cutting efficiency, inability to achieve multi-angle cutting, etc., to ensure tightness, guarantee The effect of cutting efficiency and cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

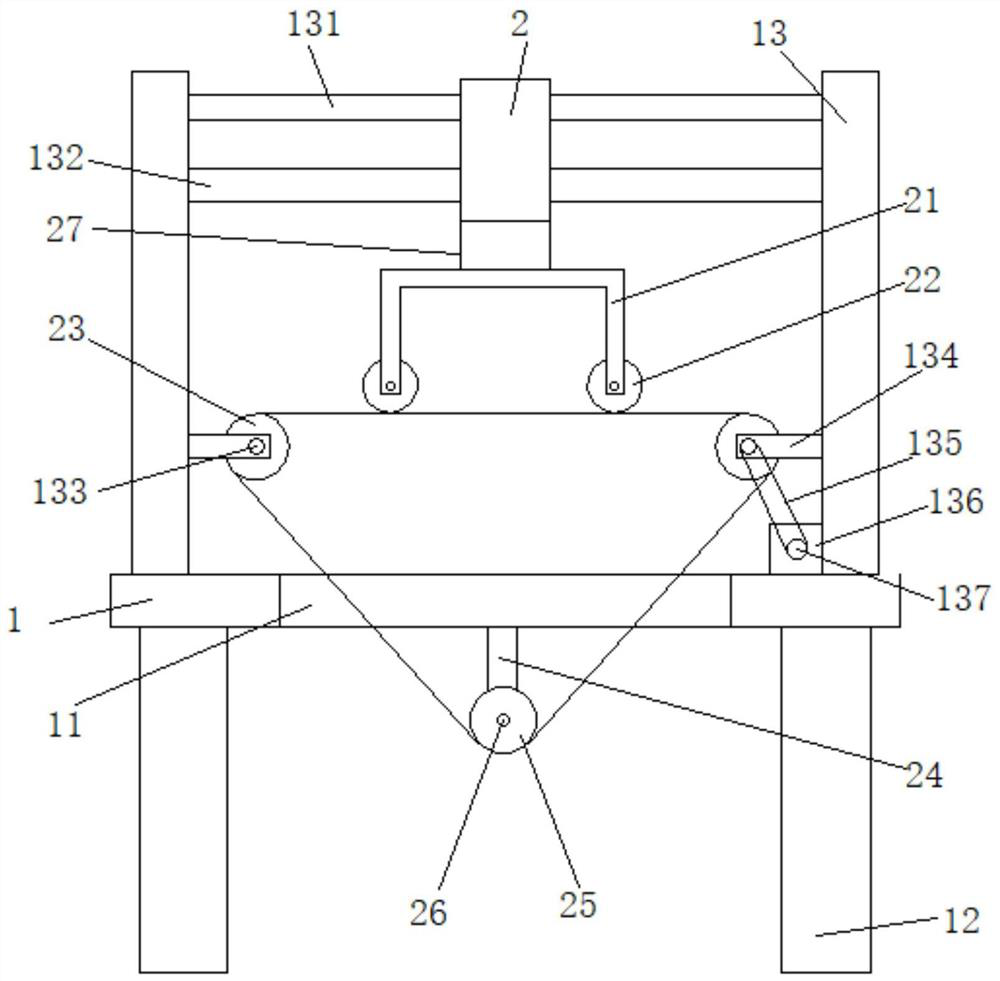

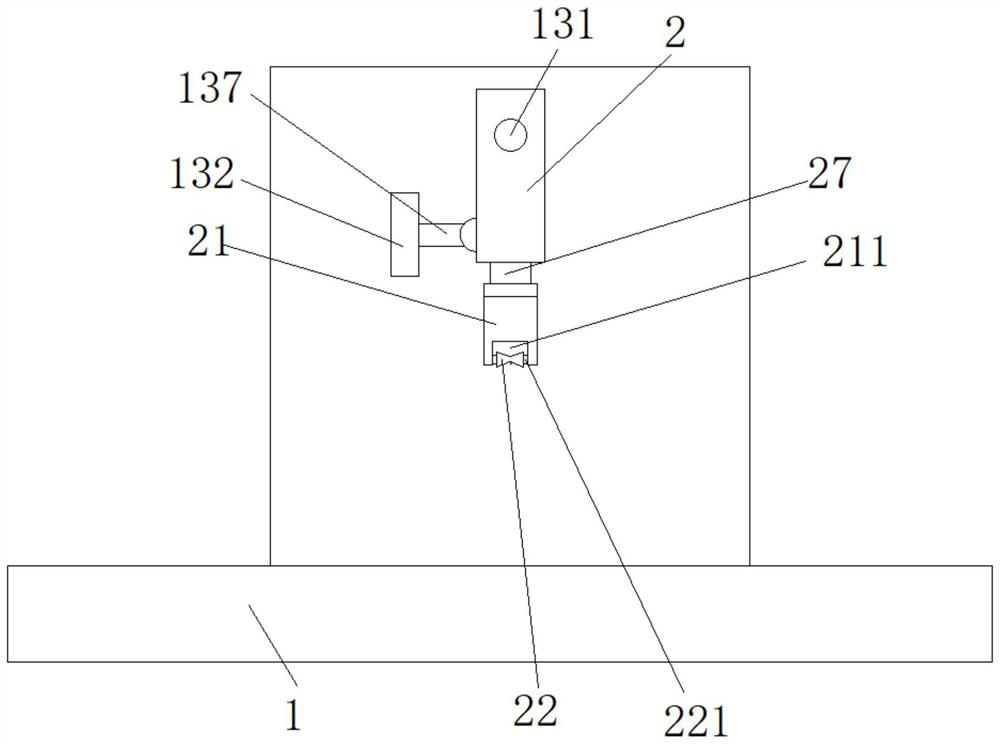

[0027] see Figure 1-2 , an automatic induction multi-angle cutting device for the production of aluminum profiles, including a cutting table 1, the cutting table 1 is provided with symmetrically distributed fixed plates 13, and the inner sides of the fixed plates 13 are provided with rotatable first fixed Pulley 23, the cutting table 1 positioned below the first fixed pulley 23 is provided with a through-type cutting groove 11, and the bottom of the cutting table 1 positioned at the bottom of the cutting groove 11 is provided with a second fixed pulley 25 that can move up and down. A cutting line 28 connected between the first fixed pulley 23 and the second fixed pulley 25 is provided, and a U-shaped cutting frame 21 is arranged above the cutting line 28 between adjacent first fixed pulleys 23, Both ends of the cutting frame 21 are provided with adjustment grooves 211, and a rotatable cutting pulley 22 is arranged in the adjustment groove 211. The cutting pulley 22 is located...

Embodiment 2

[0033] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

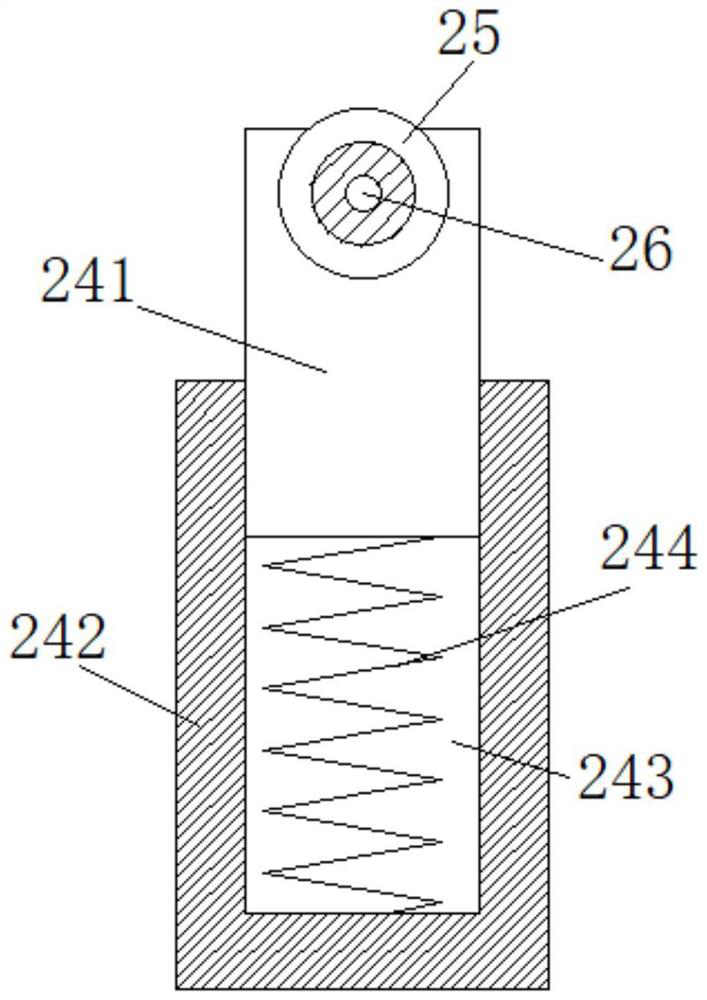

[0034] see image 3 , the retraction mechanism includes a spring 244, one end of the spring 244 is connected to the bottom of the sliding groove 243, and the other end of the spring 244 is connected and fixed to the end of the first positioning rod 241.

[0035] The spring 244 is designed so that when the cutting pulley 22 drives the cutting line 28 to move, the second fixed pulley 25 can move up and down correspondingly, so that the cutting line 28 can effectively cut.

Embodiment 3

[0037] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0038] see Figure 4 , the retraction mechanism includes a pressure sensor 246 and a third hydraulic rod 245, the chute 243 is provided with a fixedly connected third hydraulic rod 245, the extension end of the third hydraulic rod 245 is connected to the end of the first positioning rod 241 The parts are connected and fixed, and the connection between the third hydraulic rod 245 and the first positioning rod 241 is provided with a pressure sensor 246 for sensing pressure changes, and the pressure sensor 246 is electrically connected with the third hydraulic rod 245 .

[0039] The design of the third hydraulic rod 245 and the pressure sensor 246, through the precise induction of the pressure sensor 246, can adjust the expansion and contraction of the third hydraulic rod 245 in time, which can effectively ensure the tightness of the cutting line 28 during cutting, thereby ensuring overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com