Fiber grating sensor for simultaneously measuring two-dimensional inclination and vibration and measurement method thereof

A fiber grating and sensor technology, applied in measuring devices, instruments, etc., can solve the problems of non-reuse, incomplete monitoring of slope safety information, and difficult removal of sensors, etc., to achieve cost saving, simple structure, and accurate alarm effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

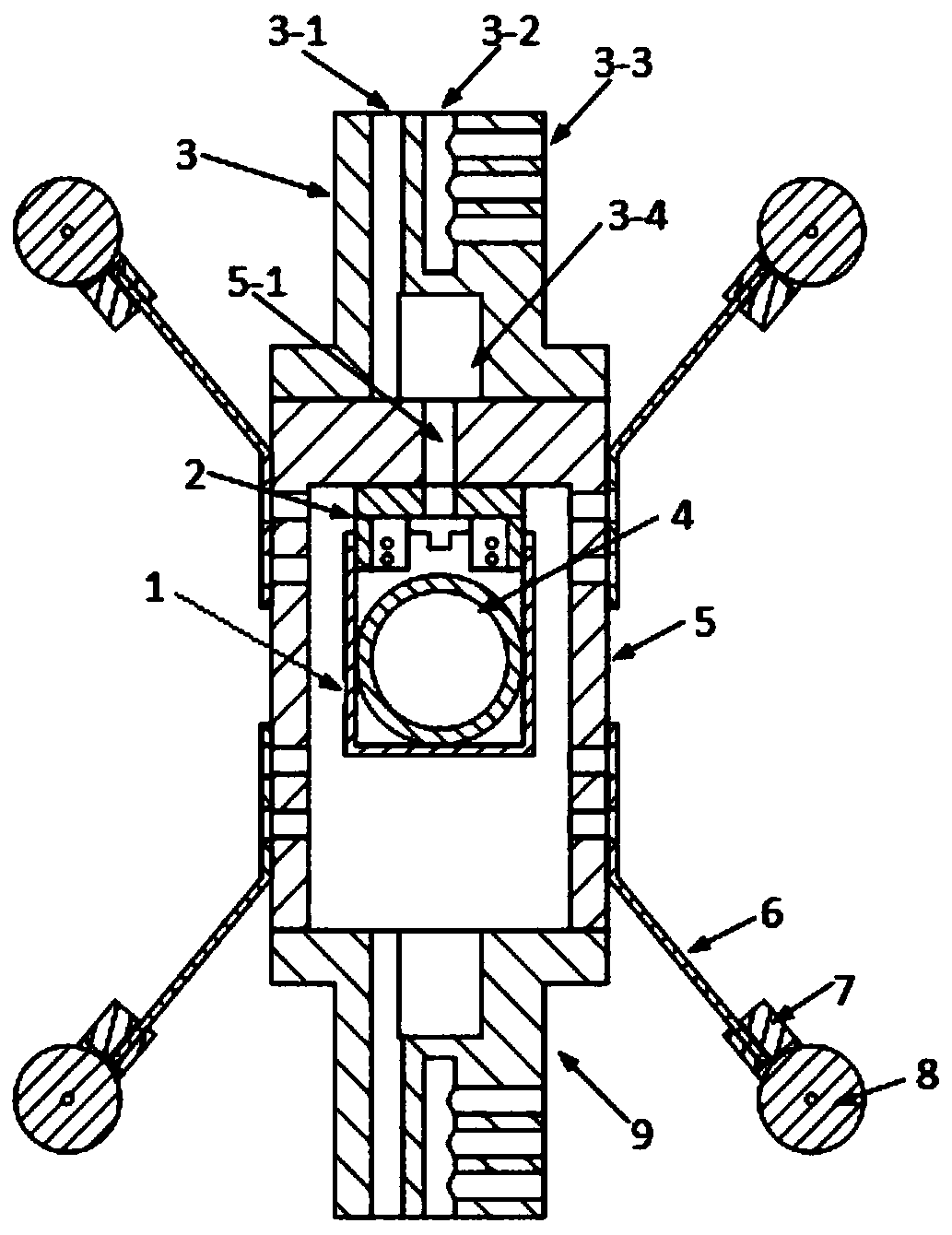

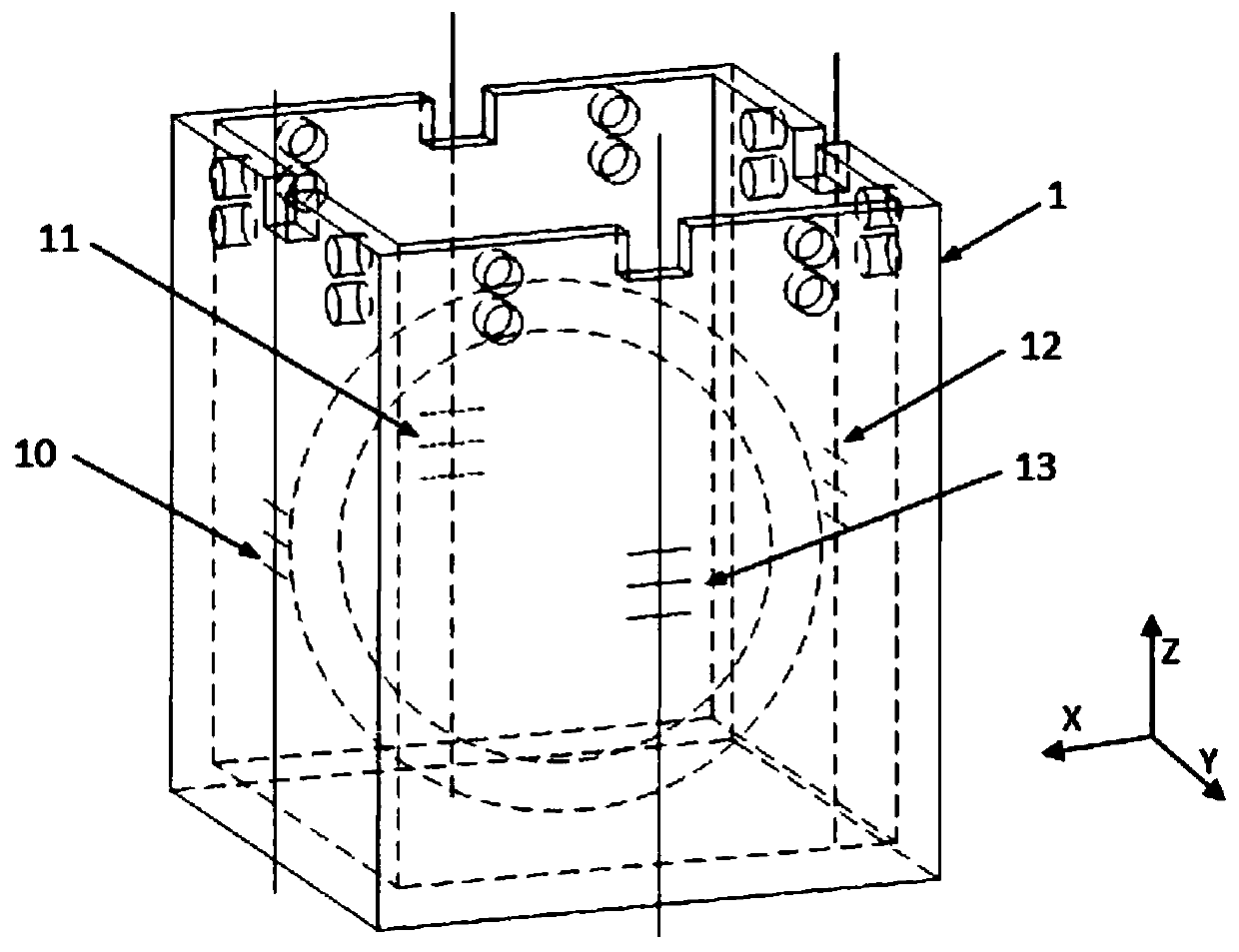

[0043] Such as figure 1 As shown, a fiber grating sensor for simultaneous measurement of two-dimensional tilt and vibration is mainly composed of a thin-walled square tube 1, a thin-walled square tube fixing seat 2, a hanging plate 3, a ball 4, a housing 5, a roller elastic support 6, Roller support 7, roller 8, lower hanging plate 9 form. Put the ball 4 into the thin-walled square tube 1, the ball 4 is tangent to the four inner walls of the side of the thin-walled square tube 1, and glue and fix it at the tangent position, and the thin-walled square tube 1 opposite to the glued position Paste 4 fiber gratings on the outer wall.

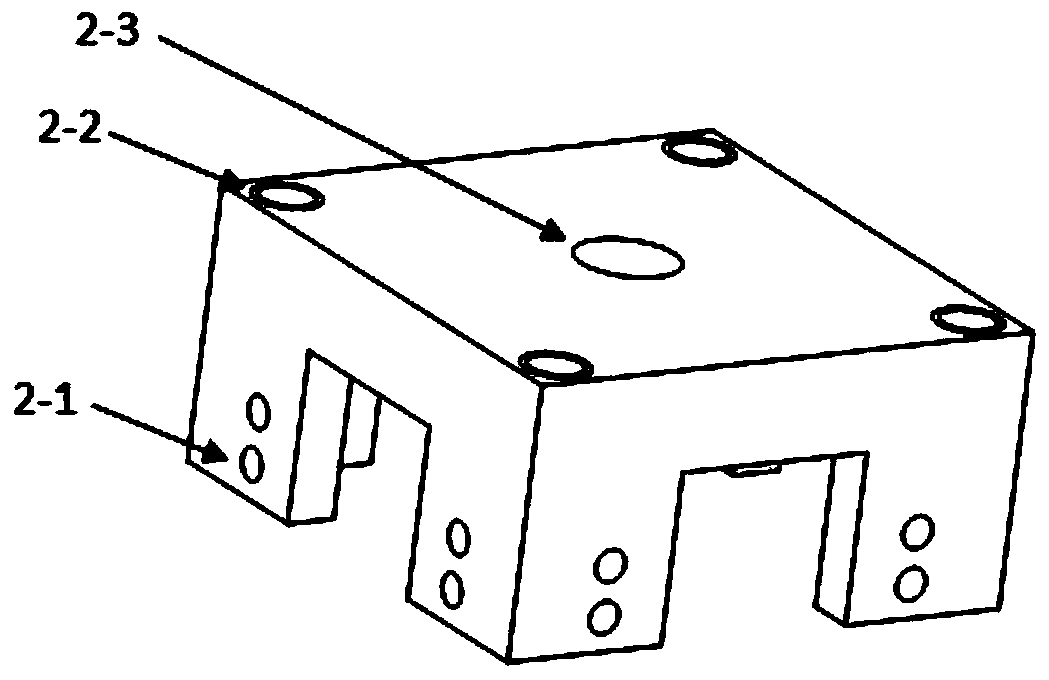

[0044] After the fiber grating is pasted, the optical fiber at the upper end of the thin-walled square tube 1 is drawn out through the first fiber outlet hole 2-3 of the thin-walled square tube holder 2, and the thin-walled square tube holder 2 is slowly inserted into the thin-walled square tube In the cylinder 1, the first threaded hole 2-1 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com