Apparatus and method for calibrating accelerometer by using bullet beam with variable cross-section to generate wide pulse

A technology of accelerometer and variable cross-section, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measurement devices, etc., which can solve large calibration errors, excitation pulse frequency cannot be too high, Stimulate the installation natural frequency of the accelerometer to be tested, etc., to achieve the effect of easy and feasible assembly and prolonging the pulse width of the excitation pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

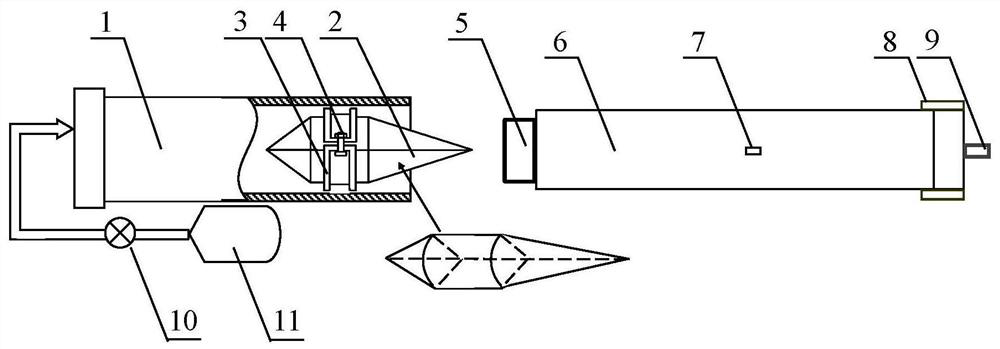

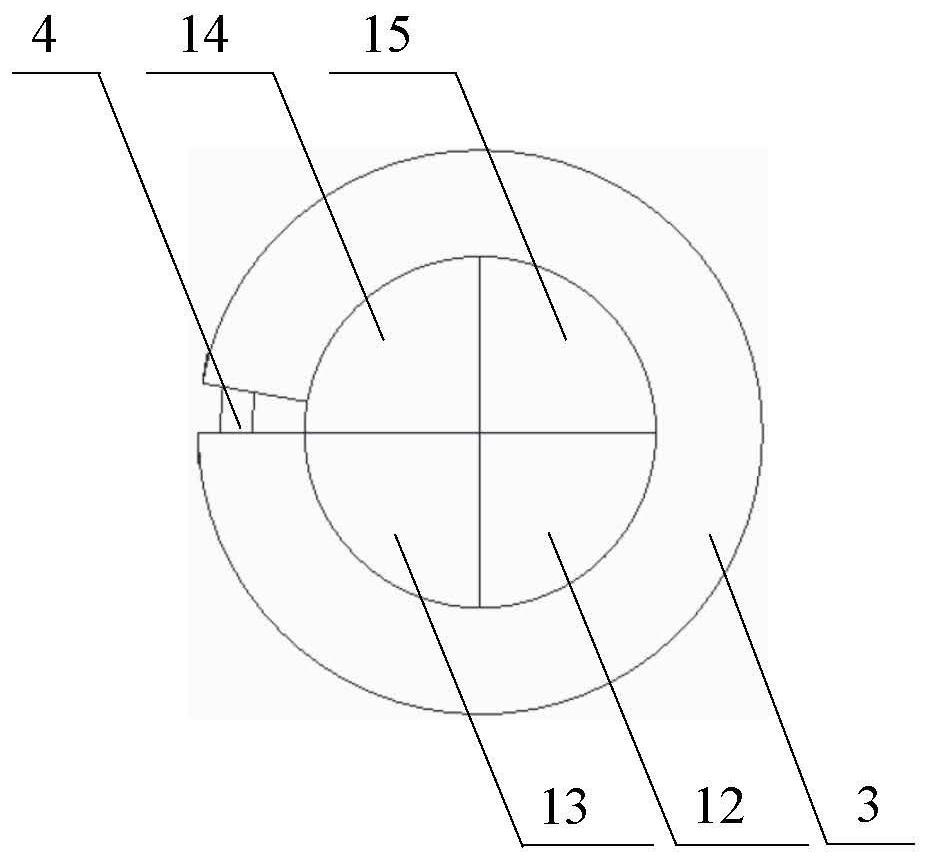

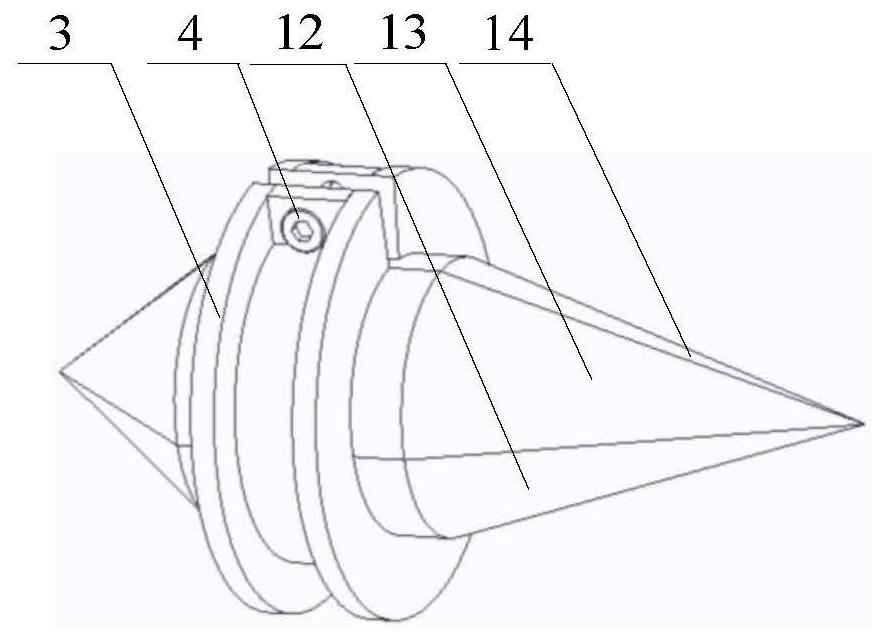

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0031] The technical scheme adopted in the present invention is: as figure 1 As shown in and 2, the bullet with tapered ends at both ends and a cylindrical bullet in the middle is cut along two geometric symmetry planes orthogonal to the axial direction. The last four bullets all have the same variable-section geometric characteristics, thereby ensuring that when any number of bullets are selected for impact, the generated excitation pulse width has the same pulse width and amplitude variation characteristics. At the same time, in order to protect the impact end of the calibration rod, a large size shaper is selected as protection. According to the selection rules of the shaper, the shaper with a larger thickness and size will have a smaller shaping effect. Therefore, when any number of bullets are used for impact, the shaper with an oversized size will have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com