Preparation method and application of phosphorus modified supported bimetallic catalyst

A bimetallic catalyst, supported technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the complex effect of hydrogenation activity and reduce catalyst activity. , the aggregation of active particles, etc., to achieve the effect of improving catalyst activity, improving hydrogenation rate, and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

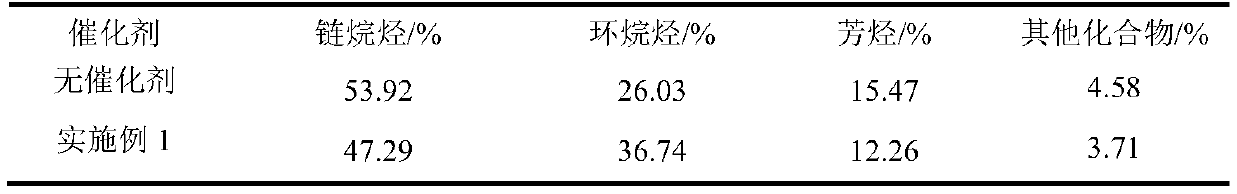

Examples

preparation example Construction

[0028] The preparation method of the phosphorus-modified supported bimetallic catalyst provided by the invention comprises: (1) selecting gamma-Al 2 o 3 as carrier, ready for use, γ-Al 2 o 3 The particle size of the carrier is 20-30 mesh; (2) Dissolving nickel salt, tungstate and phosphorus reagent in deionized water according to a certain ratio, as an impregnating solution, for use; wherein, the phosphorus reagent is phosphoric acid, pyrophosphoric acid, metaphosphoric acid, Phosphoric acid, polyphosphoric acid or its mixture; (3) the γ-Al of step (1) 2 o 3 The carrier is put into the impregnating liquid of step (2), and the impregnating liquid and γ-Al 2 o 3 The volume of the carrier is equal, and the impregnated carrier is treated in a microwave chemical reactor, the microwave power is 300-900W, the heating temperature is 40-80°C, filtered after treatment, and the filter cake is dried in an oven for 4-24h, and set aside; (4) The filter cake dried in step (3) is placed...

Embodiment 1

[0031] Use γ-Al 2 o 3 As a carrier, the particle size of the carrier is 20 mesh, 2.53g Ni(NO 3 ) 2 ·6H 2 O and 20.53g (NH 4 ) 6 W 7 o 24 ·6H 2 O, 0.33g phosphoric acid, added to 200ml deionized aqueous solution to make impregnation solution, 7.69g γ-Al2 o 3 Mix with the prepared impregnation solution by equal volume impregnation method, in which NiO and WO 3 The total load is 23%, the phosphorus load is 0.9%, and the carrier γ-Al is contained 2 o 3 The impregnation solution was treated in a microwave chemical reactor with a temperature of 60°C and a power of 600W, and then filtered. The filter cake was dried in an oven at 105°C for 4 hours, placed in a microwave tube furnace, and heated at a rate of 40°C / min in a nitrogen atmosphere. The temperature was raised to 400° C., and calcined for 2 hours to obtain a phosphorus-modified supported bimetallic catalyst.

Embodiment 2

[0033] Different from the above examples, 2.53g Ni(NO 3 ) 2 ·6H 2 O and 20.53g (NH 4 ) 6 W 7 o 24 ·6H 2 O, 0.33g of metaphosphoric acid was added to 200ml of deionized aqueous solution to make an impregnation solution, and 7.69g of γ-Al with a particle size of 30 mesh 2 o 3 Mix with the prepared impregnation solution by equal volume impregnation method, process and filter in a microwave chemical reactor with a temperature of 40°C and a power of 900W, dry the filter cake in an oven at 105°C for 6 hours, put it in a microwave tube furnace, and place it in a nitrogen atmosphere The temperature was raised to 400°C at a rate of 40°C / min and fired for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap