Zipper tooth manufacturing device and method and tooth arranging device

A technology for manufacturing devices and chain teeth, which is applied in the field of zipper manufacturing. It can solve problems such as missing teeth, easy flying out, and affecting the zipper manufacturing process, and achieve the effects of improving production efficiency, avoiding missing teeth, and increasing the height distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

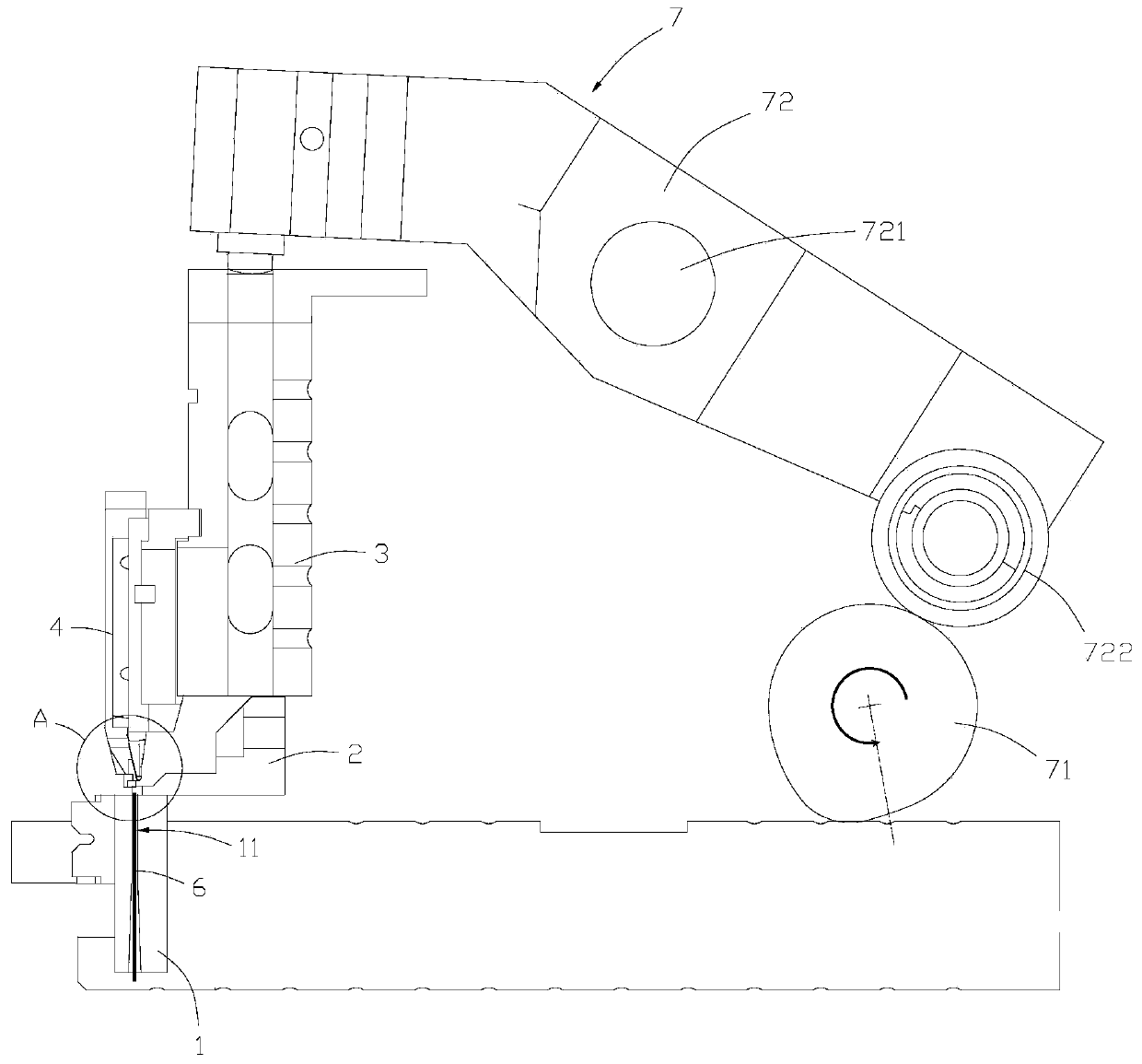

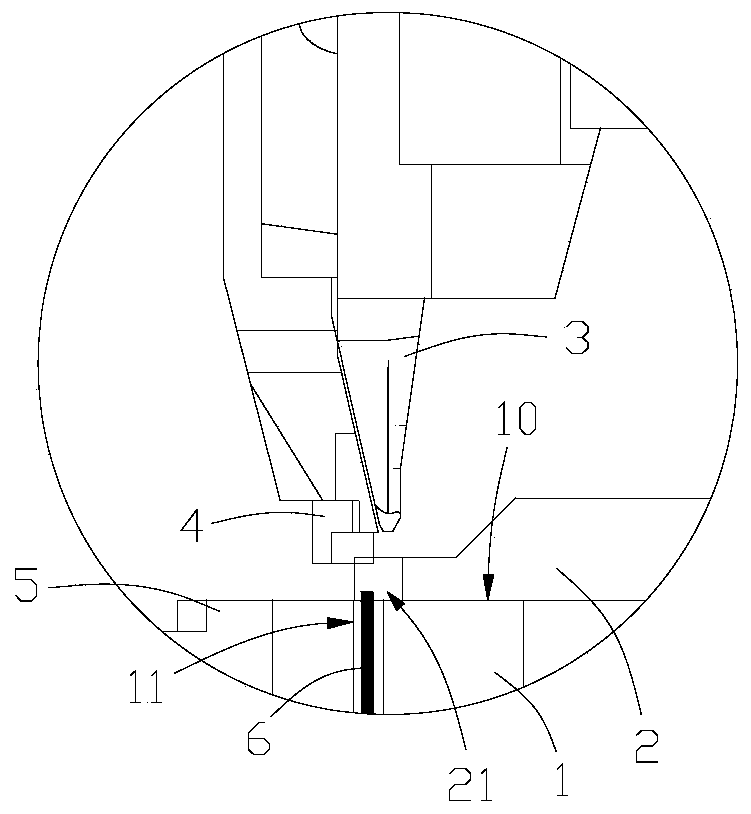

[0039] see Figure 1 to Figure 8 , the present invention provides a fastener element manufacturing device for a zipper, comprising a slide 1 and a cutter 2, a punch 3 and a stripper 4 arranged above the slide 1, and a cutting plane 10 is provided on the upper side of the slide 1 , the interior is provided with a wire channel 11 extending longitudinally from the bottom surface of the slide seat 1 to the cutting plane 10, and the front side is connected with a punching die 5, and the punching die 5 is provided with a forming part 51 located below the cutting plane 10, The wire channel 11 is for the wire 6 to be intermittently delivered to the top of the cutting plane 10 with a preset supply amount every time, and the intermittent delivery of the wire 6 is realized by the feeding mechanism, because the feeding mechanism is not an improvement of the present invention, and the existing Known scheme, so it will not be described in detail; the sliding seat 1 is realized by a driving ...

Embodiment 2

[0047] see Figure 1 to Figure 8 , the present embodiment provides a fastener element manufacturing method of a zipper, which relates to a fastener element manufacturing device, the fastener element manufacturing device includes a slide 1, a punching die 5, a cutter 2, a punch 3 and a stripper 4, the The punching die 5 is arranged on the front side of the slide seat 1, the upper side of the slide seat 1 is provided with a cutting plane 10, and the inside is provided with a wire channel 11 extending longitudinally from the bottom surface of the slide seat 1 to the cutting plane 10, and the punching die 5 is provided with a There is a forming part 51 located below the cutting plane 10. The sliding seat 1 is reciprocated and translated back and forth by the driving mechanism. The cutting knife 2 is in sliding contact with the cutting plane 10. The cutting edge 21 of the cutting knife 2 corresponds to the The wire channel 11, the punch 3 is arranged above the cutting edge 21 in a ...

Embodiment 3

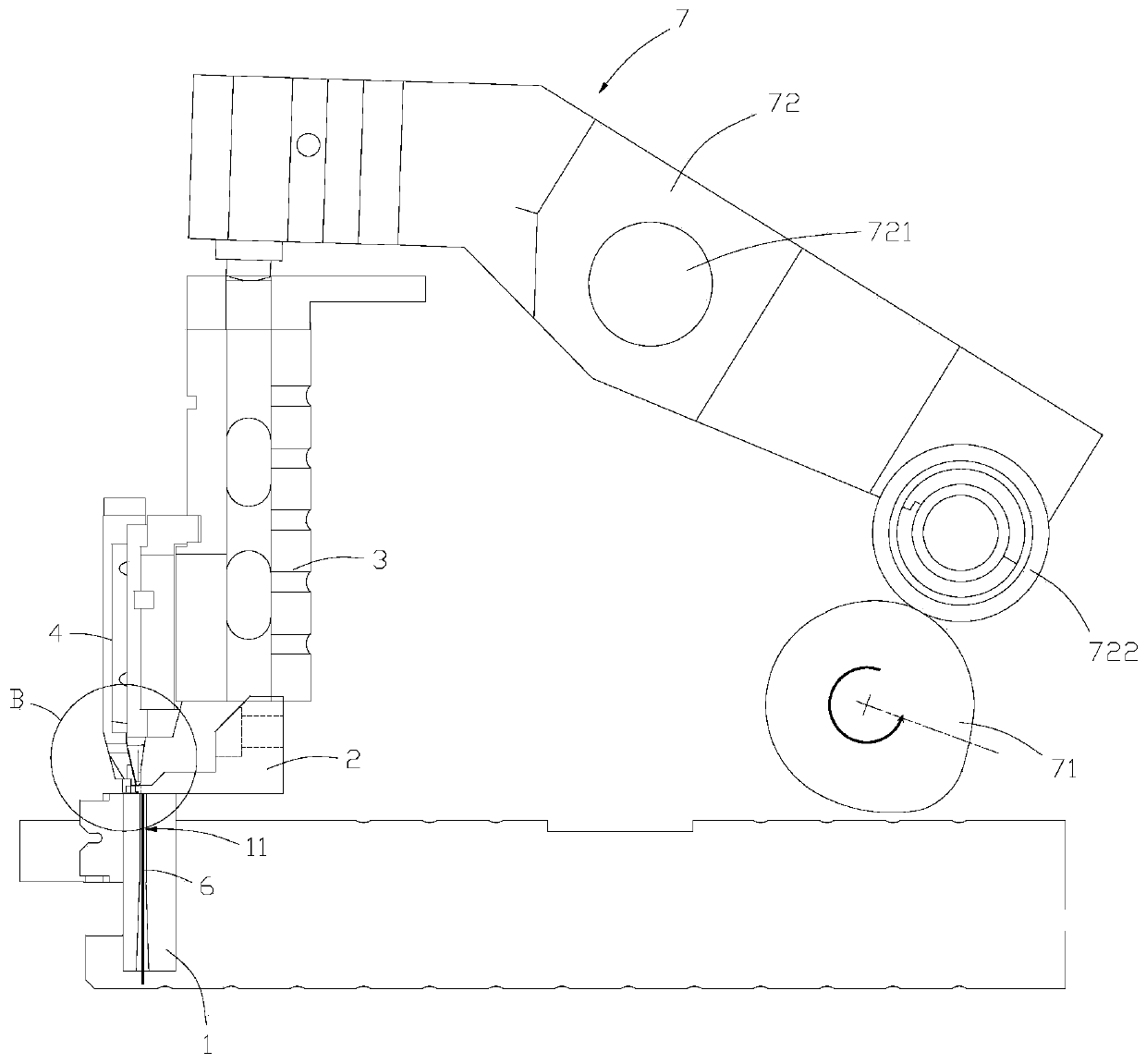

[0052] see Figure 7 , Figure 8 , Figure 10 and Figure 11 , the present embodiment provides a zipper tooth arranging device, which includes the above-mentioned fastener element manufacturing device, a tape supply mechanism and a material clamping mechanism, and the tape supply mechanism includes a feed frame fixed on the front side of the forming part 51 100, the feeding frame 100 is used to load the tape and intermittently convey upwards each time with a preset supply amount, the clamping mechanism includes clamping assemblies 8 arranged on opposite sides above the forming part 51, each side The clamping assembly 8 respectively includes a first clamping arm 81 located on the upper side of the forming part 51 and a second clamping arm 82 located on the upper side of the first clamping arm 81. 100 enters the slot 52 of the forming part 51, when the teeth are arranged, the slide seat 1 moves forward so that the feeding frame 100 is placed in the forming part 51 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com