Hourglass-shaped forging method for preventing surface cracks

A surface crack, hourglass-shaped technology, applied in the field of forging, can solve problems such as surface cracks, achieve uniform deformation, improve deformation uniformity, and facilitate engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

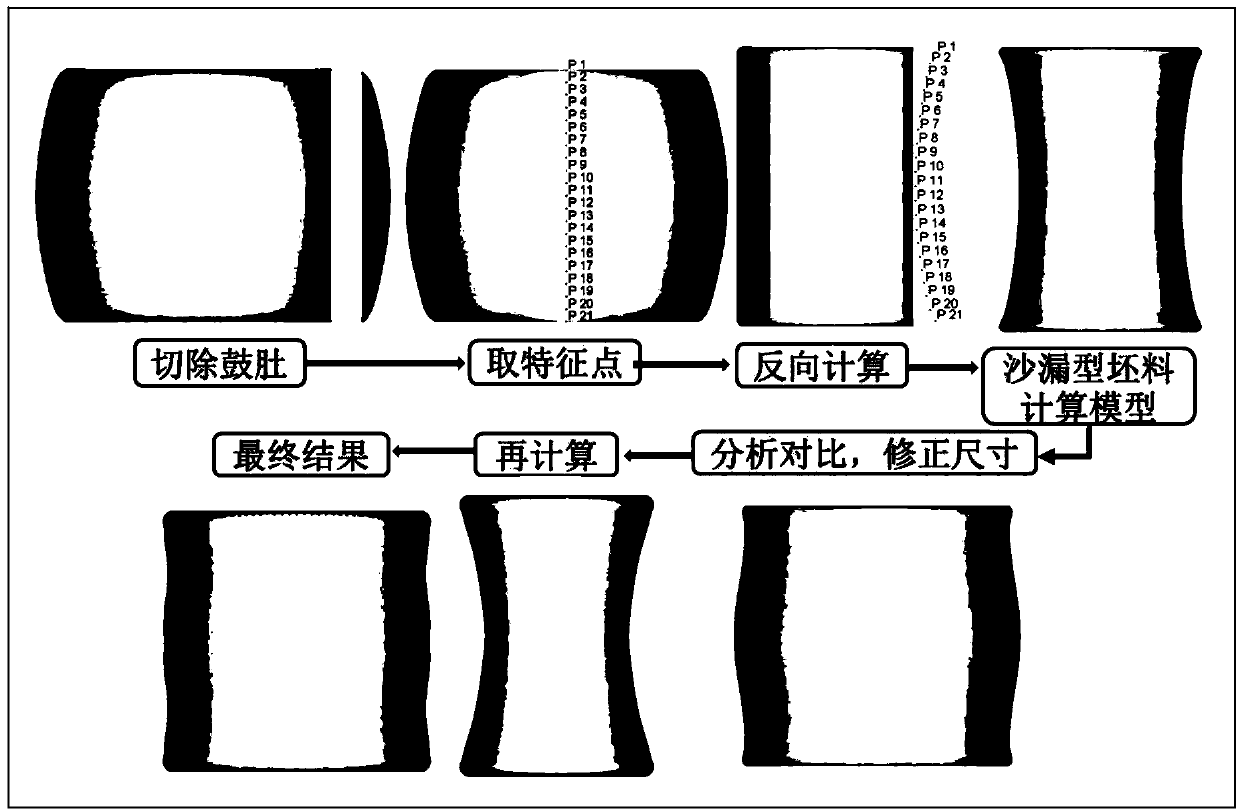

[0040] like figure 1 As shown, the embodiment of the present invention provides a method for simulating and determining the hourglass-shaped process design. Computer simulation software is used to calculate the upsetting and pressing process of ordinary cylindrical blanks. The bulge produced by pressing is used to mark the feature points and reverse calculation to obtain the position of the feature points in the original blank, and based on this, the calculation model of the hourglass-shaped blank is designed. Simulate the upsetting process of the hourglass-shaped billet calculation model, analyze and compare after pressing to the required deformation, correct the size, and calculate again to obtain the size of the hourglass-shaped billet that does not produce a belly under the required upset reduction.

[0041] like figure 2 As shown, the embodiment of the present invention provides an hourglass-shaped blank with a maximum diameter of 1 m. After the first upsetting and elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com