Articulated rubber-tyred trolleybus brake system for 3 to 5 cars

A trolleybus and braking system technology, which is applied in the direction of brakes, brake components, and braking transmission devices, can solve the problem that the braking system cannot meet the braking requirements of articulated rubber-tyred trolleybuses with 3 to 5 carriages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

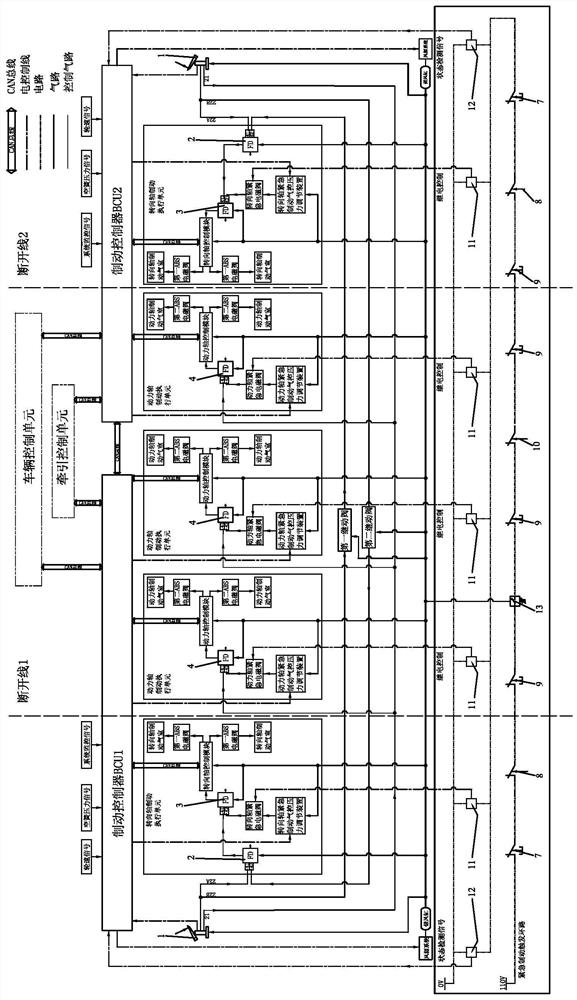

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

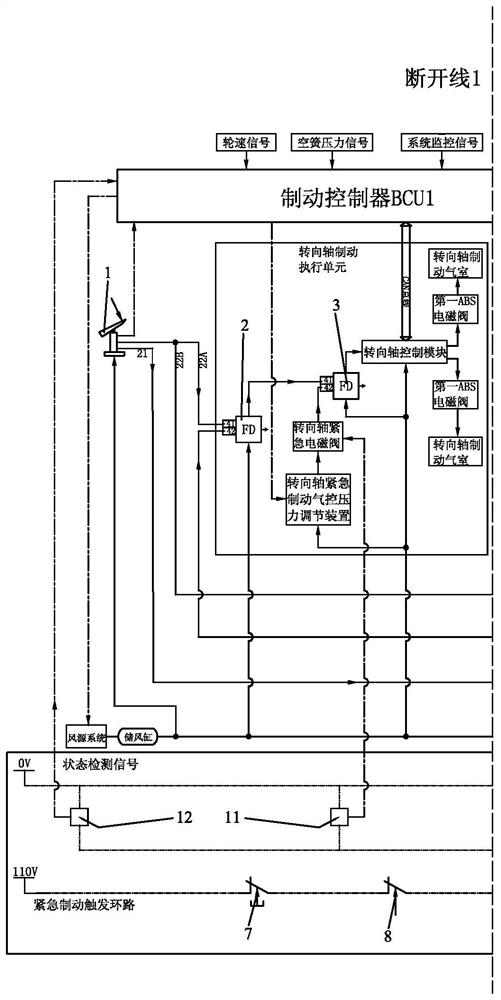

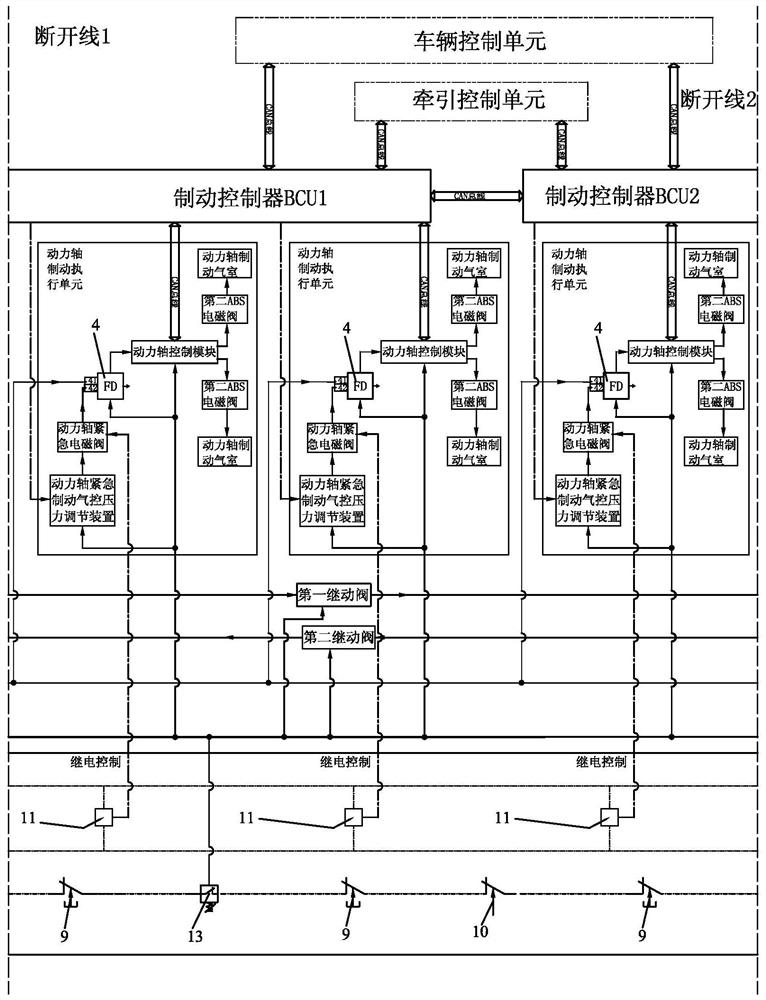

[0051] refer to Figure 1 to Figure 5 , The braking system of the present invention is suitable for articulated rubber-tyred trolleybuses with 3 to 5 carriages, and this embodiment is applicable to the braking system for articulated rubber-tyred trolleybuses with 4 carriages. The above-mentioned model is a trolley bus with two-way driving, and the rail wheels are replaced by rubber wheels. The rubber wheels are located at the hinge of the two carriages, and there are five shafts in total, including the steering shaft 5a, the steering shaft 5b, the power shaft 6a, the power shaft 6b and the power shaft 6c. The brake system includes air source and two brake units.

[0052] Air source includes air source system and air storage cylinder.

[0053] Each brake unit includes a brake pedal 1, a brake control part and a brake execution part. The brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com