Self-locking outer edge brake

A brake and outer edge technology, applied in hoisting devices and other directions, can solve the problems of reduced braking performance, large force to release the brake, and inability to continue to use, etc., to achieve strong braking performance, fast braking response, and small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

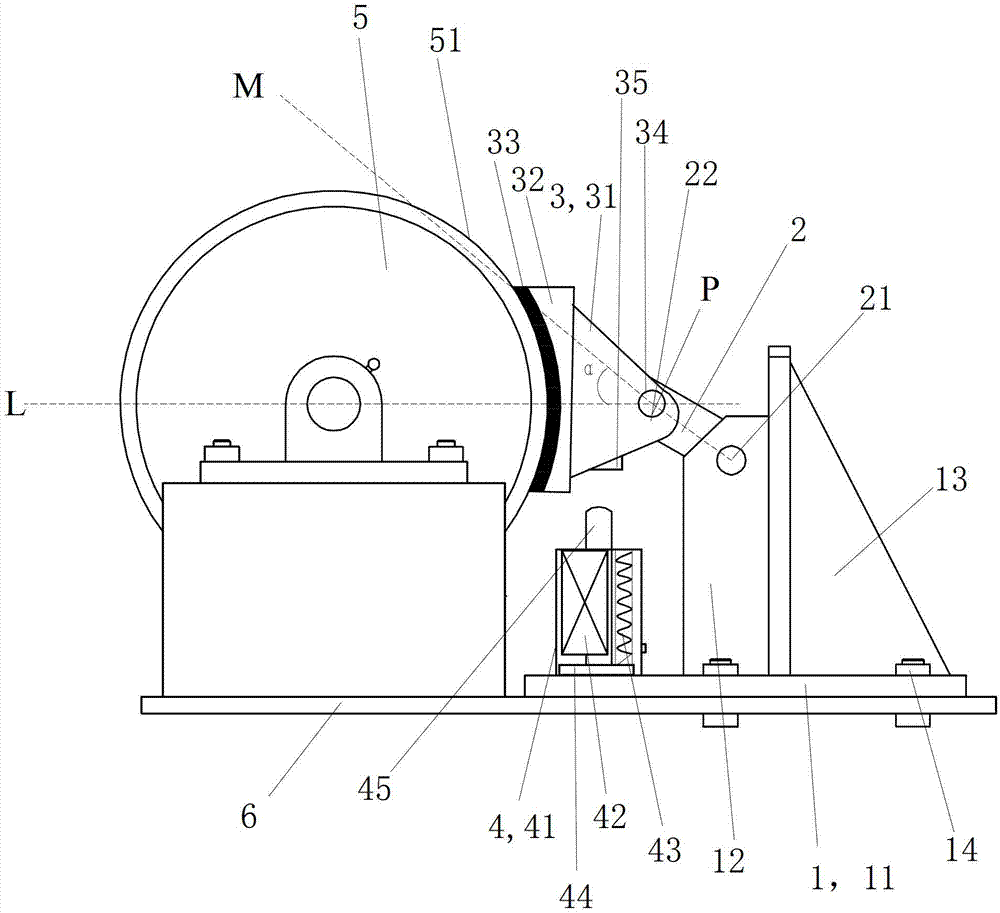

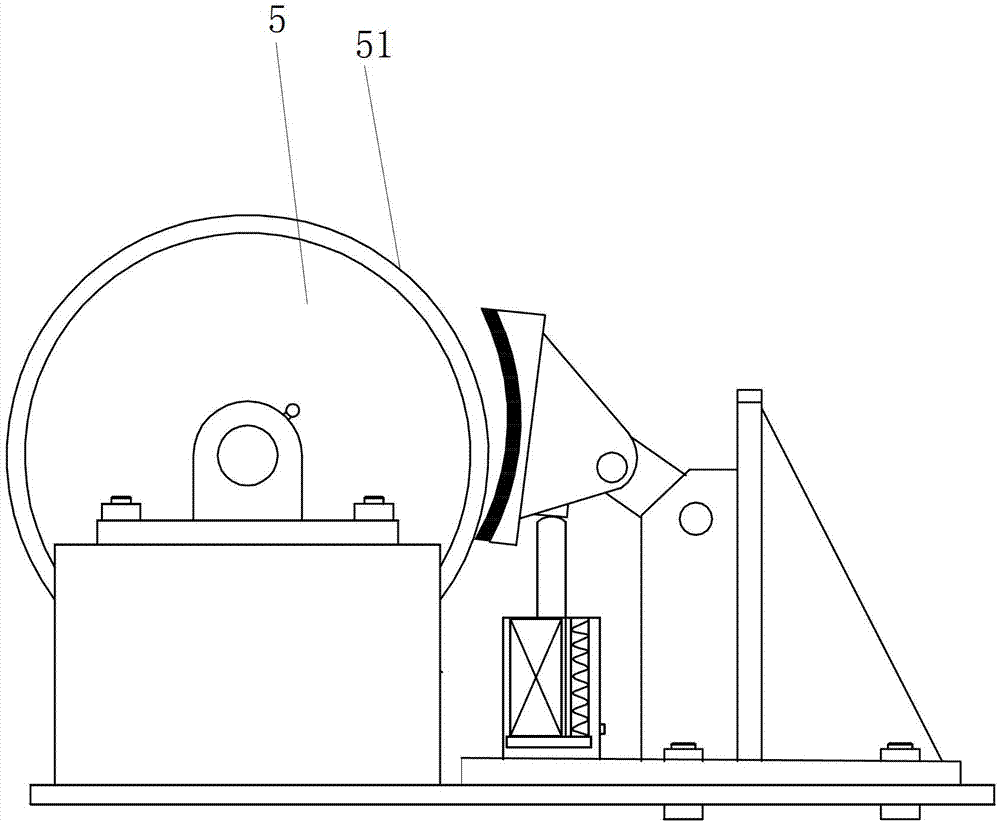

[0035] In this embodiment, the braking of the reel of the hoist hoist of the water conservancy gate is taken as an example for illustration. The hoist hoist includes a frame 6, a bearing seat, a bearing, a drum shaft, a drum and a brake disc 5. Bearing seat has 2 points and is fixed on the frame 6 front and back, and bearing is fixedly installed on the reel shaft, and is also installed in the corresponding bearing seat, and reel is fixed on the reel shaft. The reel includes a cylindrical winding portion. The brake disc 5 can be a circular plate specially set and fixed at one end of the winding portion of the reel. The brake disc 5 is arranged coaxially with the rotating shaft of the reel. The brake disc 5 is welded or fixed on the reel by bolts. One end of the coil. It can also be the original rope retaining plate that doubles as a brake disc; the outer diameter of the brake disc 5 is greater than the diameter of the winding portion of the reel. The brake disc 5 includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com