High-temperature and high-pressure condensate gas wax precipitation quantity testing apparatus and method

A technology of high temperature and high pressure, testing equipment, applied in the direction of measuring equipment, specific gravity measurement, analysis of materials, etc., can solve the problems of the method of testing the amount of undesorbed wax, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

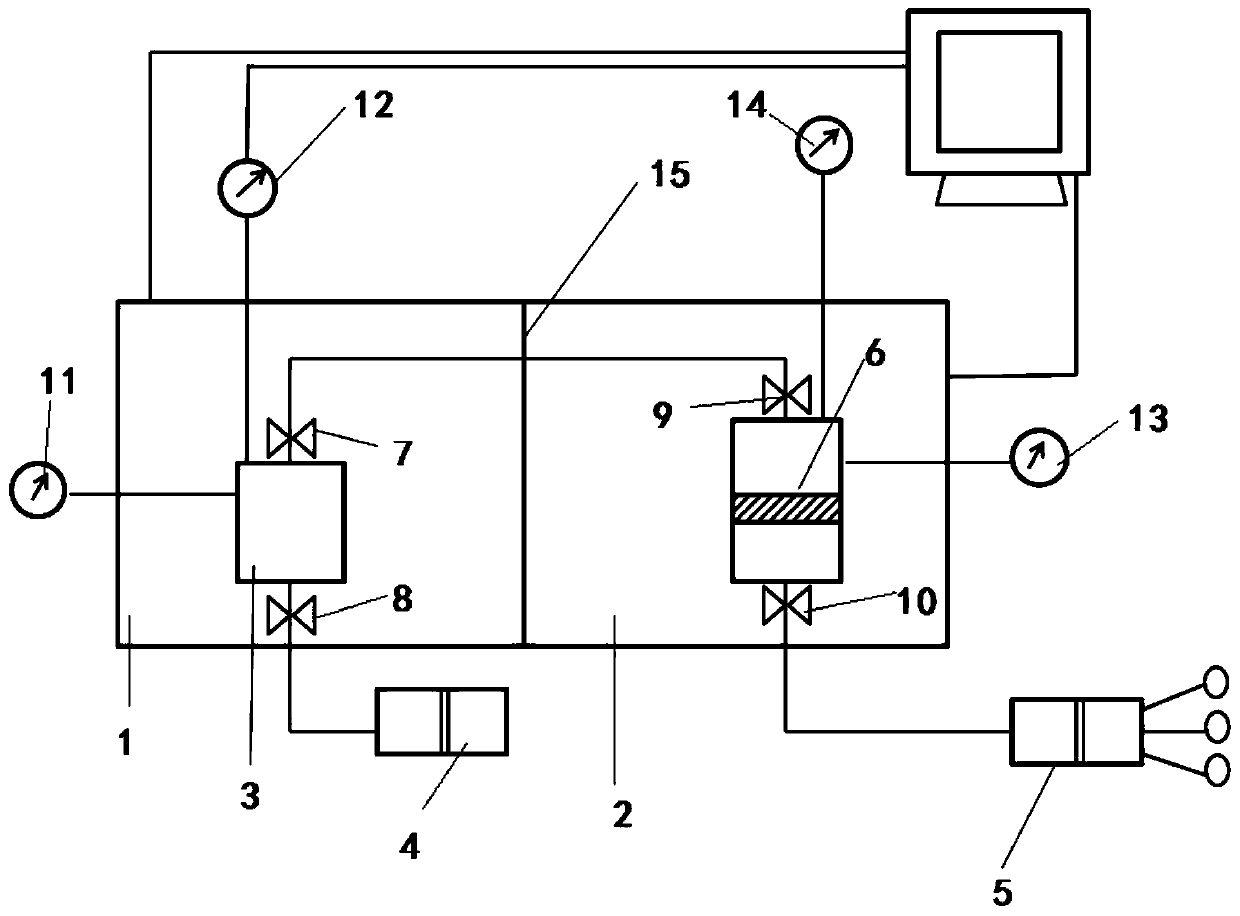

[0050] Such as figure 1 As shown, a high-temperature and high-pressure condensate gasification wax amount testing device of the present invention includes a constant temperature box I1, a constant temperature box II2, a high-pressure phase change test gas cylinder 3, a vacuum pump 4, a constant speed and constant pressure pump 5, an intermediate container 6, Computer, pipeline; heat shield 15 is provided between the thermostat I1 and thermostat II2; the vacuum pump 4, high-pressure phase change test cylinder 3, intermediate container 6, and constant-speed and constant-pressure pump 5 are sequentially connected through pipelines; Among them, metal seals are used between the pipeline and the high-pressure phase change test gas cylinder 3 and the intermediate container 6, so as to avoid the deformation of the rubber seal and cause pressure or volume cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com