Dustproof plug-in box with high heat dissipation performance

A technology with heat dissipation performance and dust prevention, applied in the electrical field, can solve the problems of inflexible configuration of radiator box, low heat dissipation efficiency, side layout, poor protection performance, etc., to avoid dust and foreign matter intrusion, simplify internal wiring of equipment, Ensuring the effect of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 19

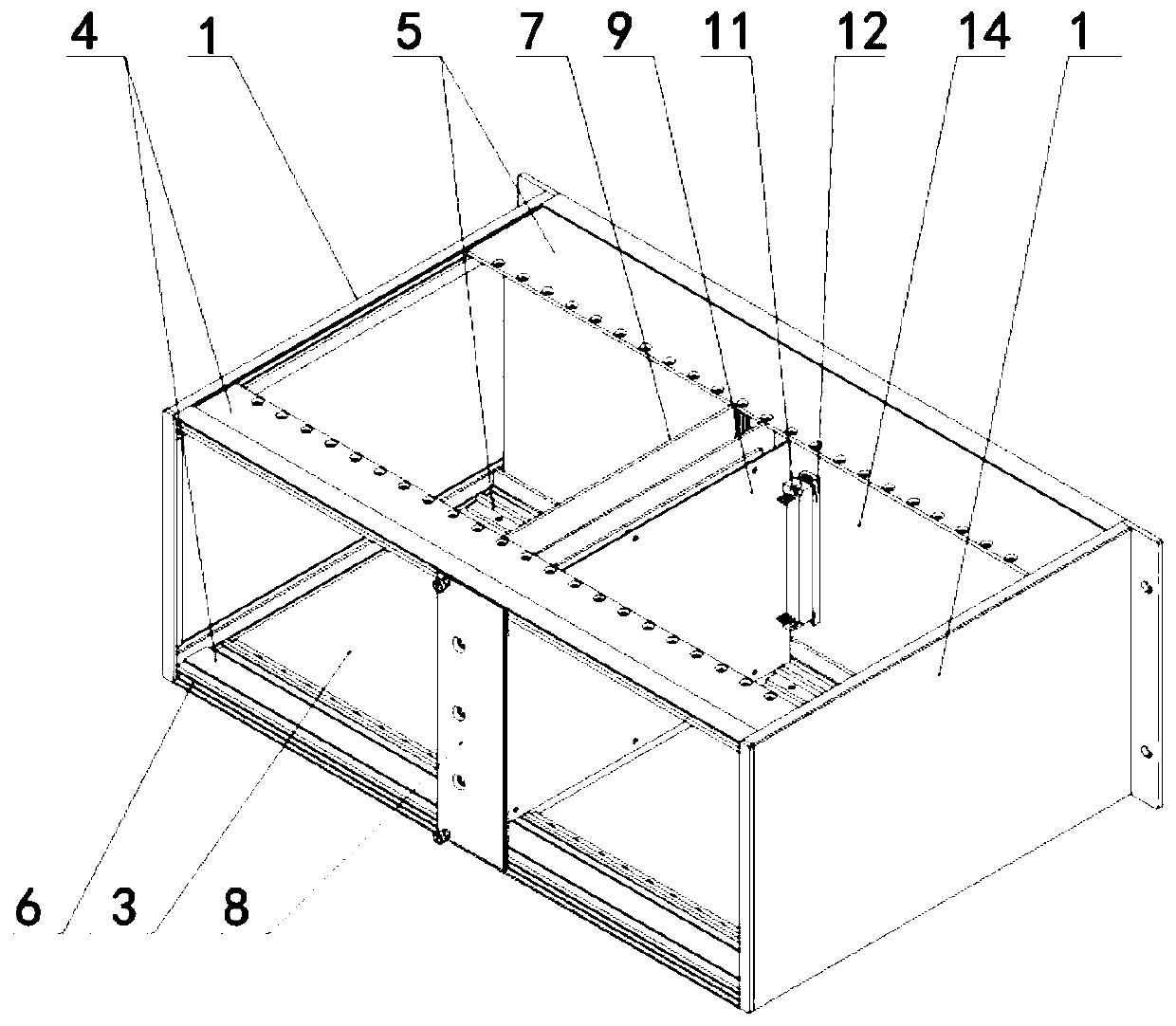

[0040] The embodiment takes the 19-inch standard box structure as an example

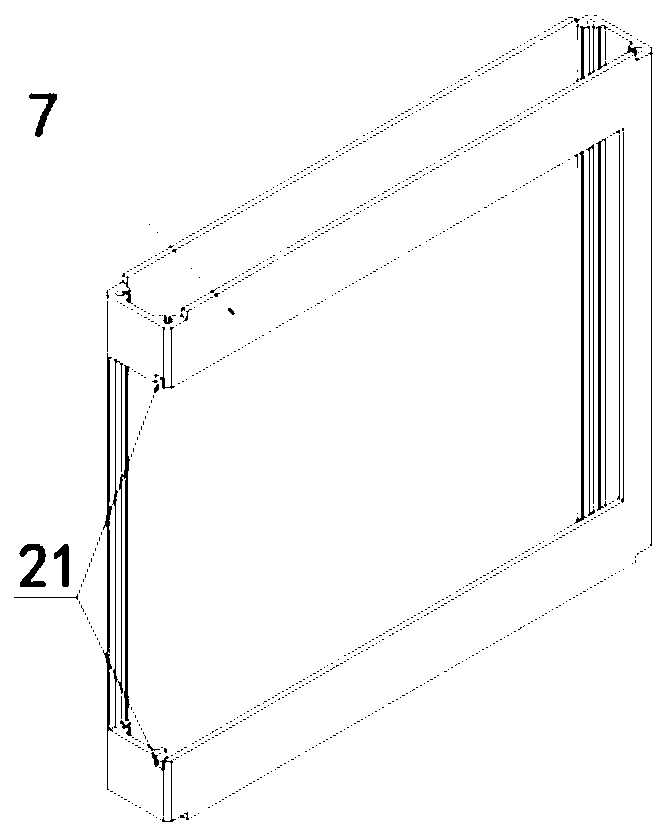

[0041] Such as Figure 1-6 As shown, a dust-proof sub-box with high-efficiency heat dissipation performance aims to solve the problems of low protection and poor heat dissipation of the existing sub-boxes with upper and lower openings. The heat dissipation module 13 is used to cooperate with the independent air duct part 7 installed in the box. The solution is to isolate the main heat of the heat source and dissipate heat outside the subrack. Its installation and implementation process are as follows.

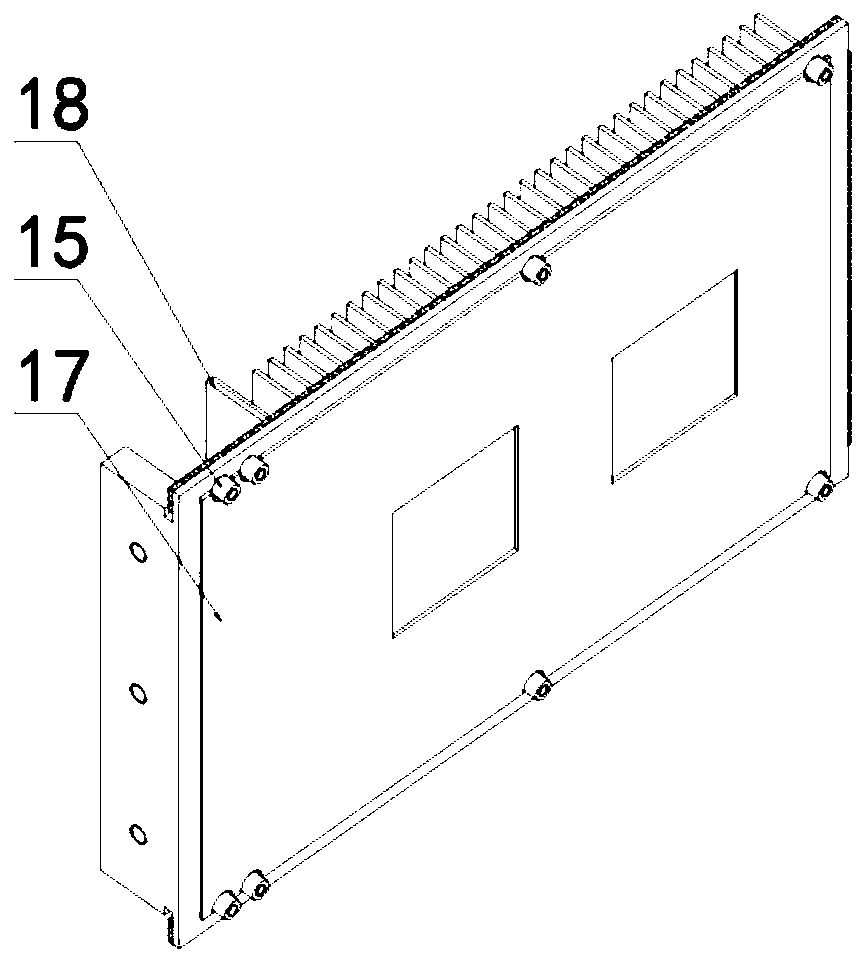

[0042] Attach the inner side of the plug-in panel 8 to the end face of the radiator module, align the holes and tighten 3 screws to fix them. Stick the adhesive side of the epoxy board 17 to the inner side of the heat dissipation module 13, cover the heat conduction pad 10 above the heat source chip 19, align the position of the heat conduction pad 10 with the square hole of the epoxy board 17, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com