Radiation-proof flexible rubber and preparation process thereof

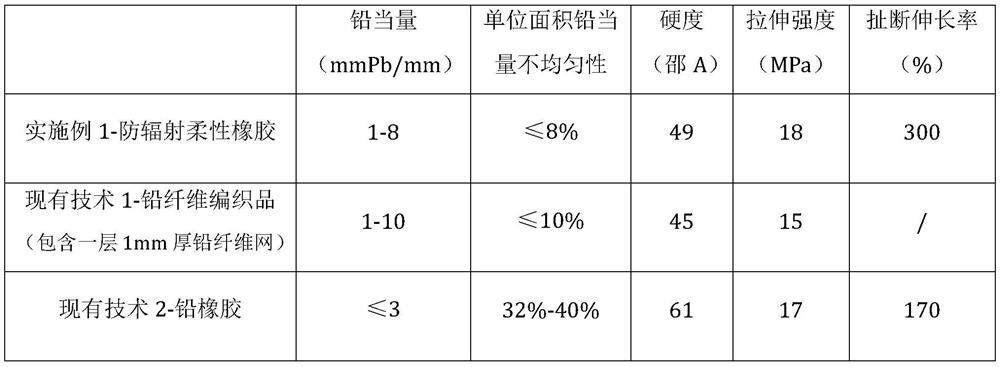

A preparation process and radiation protection technology, applied in the field of radiation protection flexible rubber and its preparation process, can solve the problems of increased lead equivalent non-uniformity, high hardness of radiation protection rubber, uneven dispersion of lead-plated carbon nanotubes, etc. Conducive to absorption and ensure the effect of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment relates to a preparation process of radiation-proof flexible rubber, comprising the following steps:

[0024] S1, weigh 5g barium sulfate, 20g carbon black, 5g zinc oxide, 1g stearic acid, 2.5g sulfur, 1.5g accelerator DM, 1.5g accelerator EZ, 0.5g antioxidant RD, 1.5g antioxidant, 0.1g Carboxymethyl cellulose, 0.1g polyvinylpyrrolidone and 65g water were mixed and treated with a sand mill for 30min to prepare filler slurry for subsequent use;

[0025] S2, adding the filler slurry prepared in step S1 to 166g of natural rubber latex, stirring and dispersing for 1 hour, to obtain prevulcanized latex;

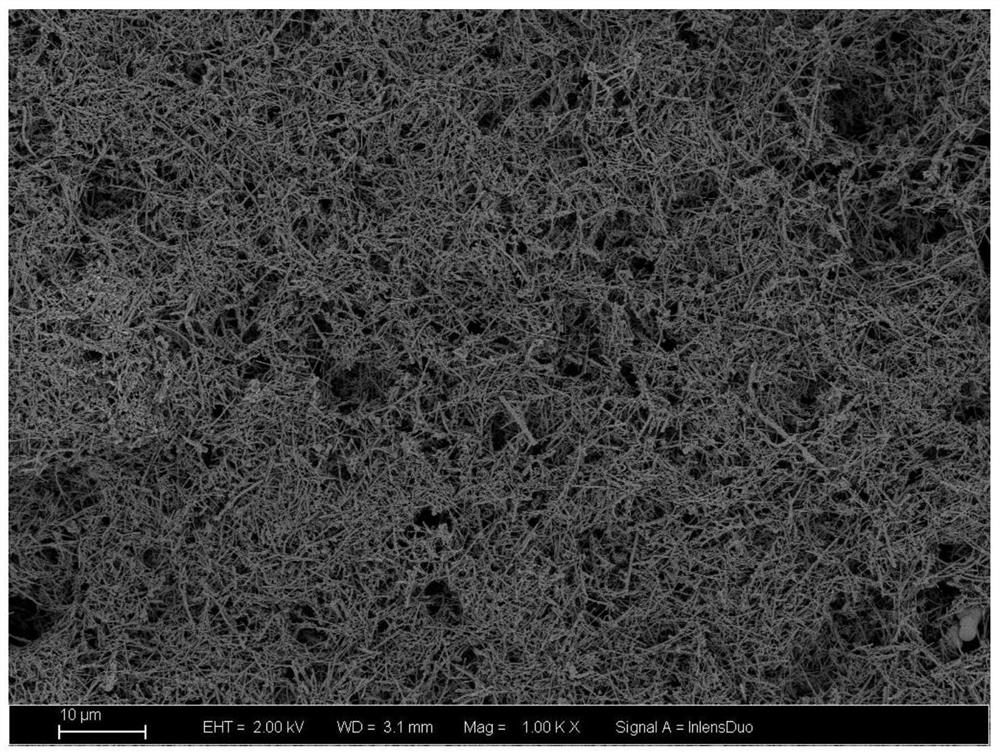

[0026] S3, spread a layer of pre-vulcanized latex in the mold, and then place a layer of 1mm thick lead-coated carbon nanotube paper (Suzhou First Element), and then pour the pre-vulcanized latex. After the pre-vulcanized latex solidifies, it is dehydrated and dried. Then put it into a vulcanization mold for vulcanization to obtain radiation-proof flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com