Slitting device for cutting machine for potato tuber production

A slitting device and potato technology, applied in rhizome seed cutting machine, seed and rhizome treatment, application, etc., can solve the problems of uneven cutting, not strict disinfection, high labor cost, etc., so as to reduce labor cost and improve seed cutting Efficiency, the effect of protecting the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

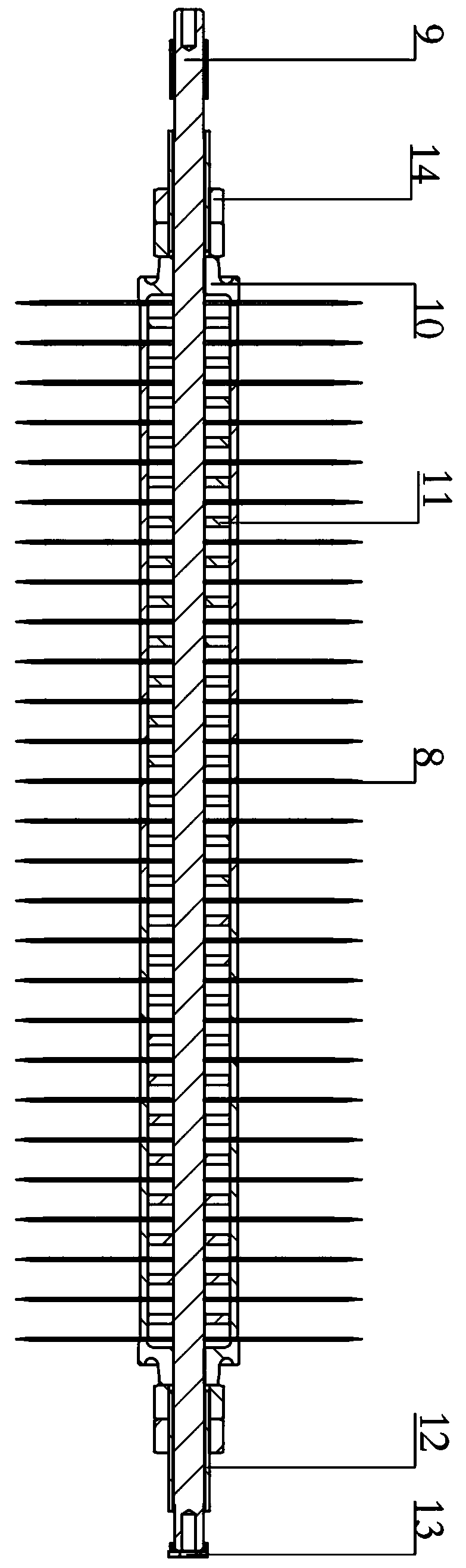

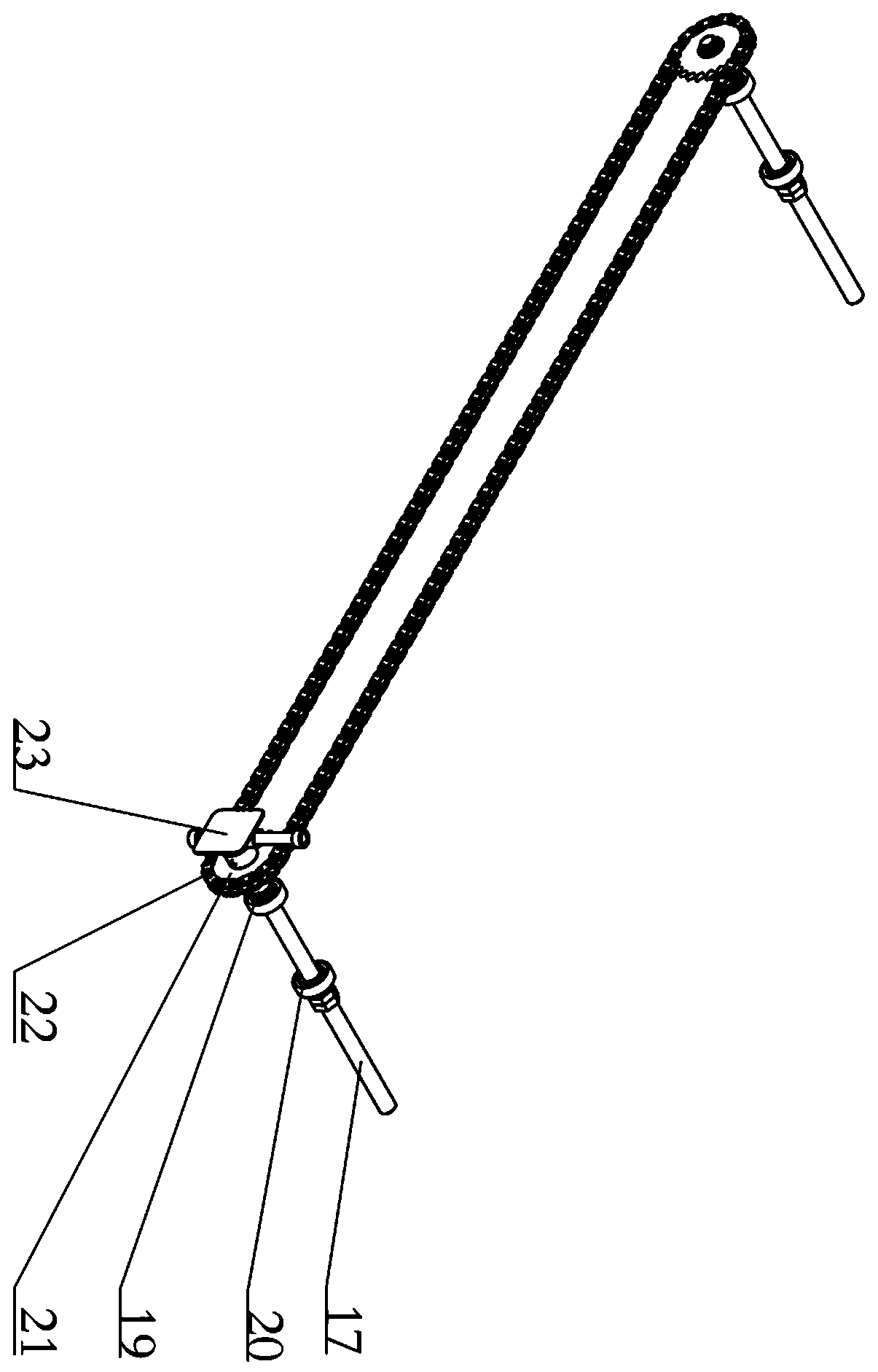

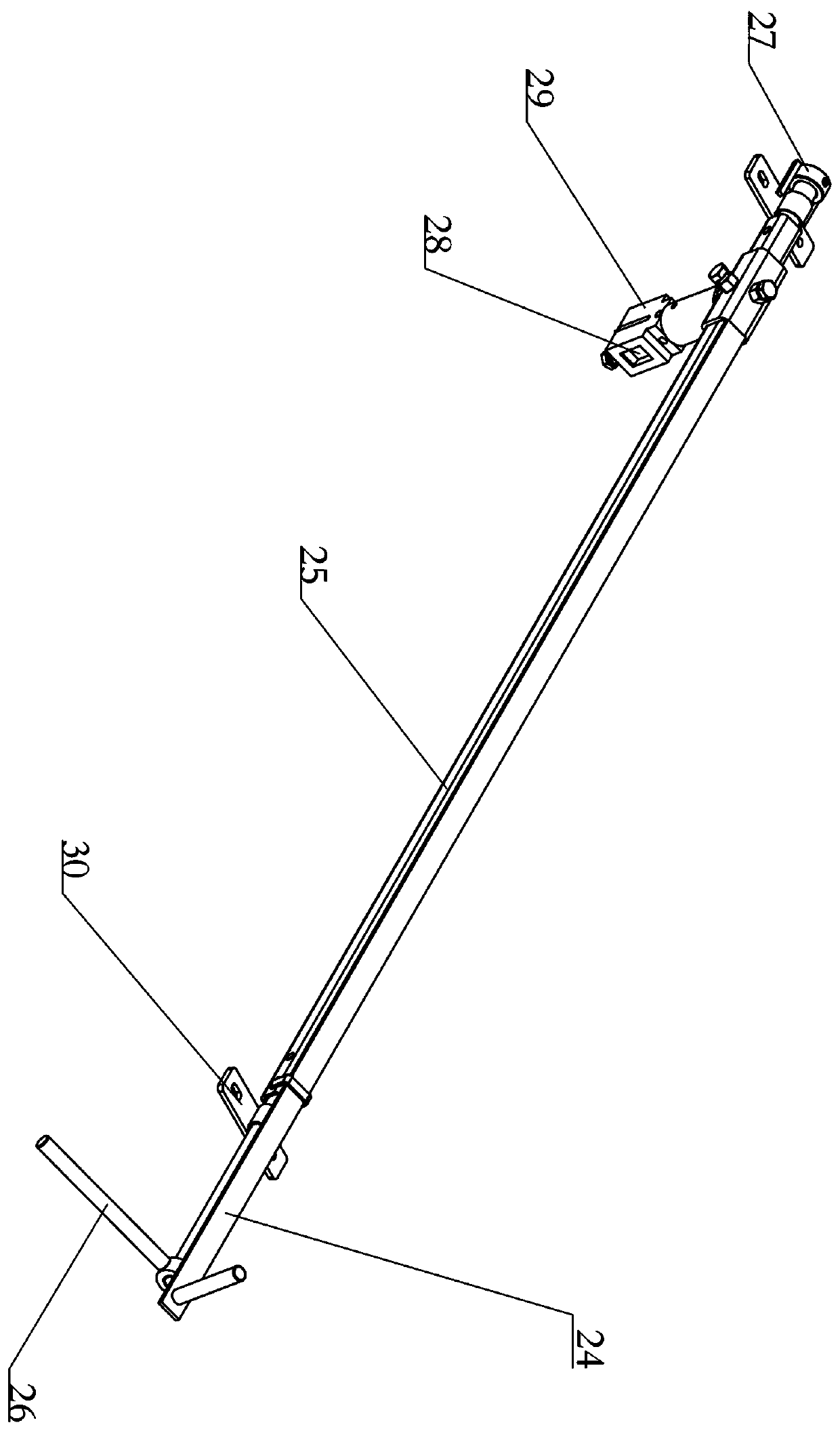

[0013] 1. Left bracket 2, right bracket 3, upper support rod 4, tension spring Ⅰ 5, tension spring Ⅱ 6, support bolt 7, travel switch fixing seat 8, disc cutter 9, cutter shaft 10, cutter gland 11. Cutter spacer 12, Cutter shaft spacer 13, Cutter shaft block 14, Nut 15, Sprocket I 16, Bearing with vertical seat 17, Lead screw 18, Lead screw sleeve 19, Spacer 20 , deep groove ball bearing 21, sprocket II 22, chain 23, adjustment handle I 24, sharpening adjustment rod 25, guide rotation shaft 26, adjustment handle II 27, positioning clamp 28, whetstone 29, knife head fixing seat 30, fixed seat.

[0014] In the present invention, "V" represents the conveying direction V of seed potatoes.

[0015] exist Figure 1~4 In the shown embodiment: parallel to each other, the plumb weights are arranged and parallel to the potato seed potato conveying direction, the left support 1 and the right support 2 of the approximate trapezoidal structure are connected with the horizontal upper supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com