Cereal meal replacement yogurt preparation method

A technology for meal replacement and yogurt, which is applied in the field of preparation of cereal meal replacement yogurt, which can solve the problems of regenerated and hardened grain particles, soft and rotten particles, and bad taste, so as to achieve complete, full, chewy and good taste. flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0053] Example 1

[0054] A preparation method of cereal meal replacement yogurt, which is prepared from the following parts by weight of raw materials:

[0055] 650 parts of fresh milk, 100 parts of white sugar, 20 parts of cream, 20 parts of oatmeal rice, 30 parts of fruit puree, 5 parts of whey protein powder, 1.5 parts of stabilizer, 1 part of food flavor, 0.01 part of lactic acid bacteria;

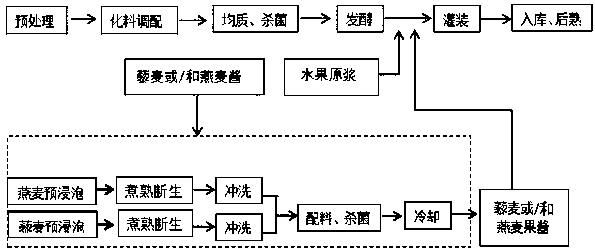

[0056] The method for preparing cereal meal replacement yogurt by taking the above-mentioned parts by weight of raw materials, such as figure 1 As shown, it specifically includes the following steps:

[0057] Pretreatment, chemical compounding, homogenization, sterilization, fermentation, filling, and maturation after storage;

[0058] The pretreatment: the raw milk is inspected and accepted after passing the inspection, and the milk is cleaned by a sterilizing separator and then cooled to 2-6°C for storage;

[0059] The compounding of the ingredients: the raw milk is heated to 65-75°C and mixe...

Example Embodiment

[0074] Example 2

[0075] A preparation method of cereal meal replacement yogurt, which is prepared from the following parts by weight of raw materials:

[0076] 680 parts of fresh milk, 90 parts of white sugar, 25 parts of cream, 22 parts of oatmeal, 25 parts of fruit puree, 8 parts of whey protein powder, 2 parts of stabilizers, 0.8 parts of food flavor, 0.015 parts of lactic acid bacteria;

[0077] The preparation method for preparing cereal meal replacement yogurt by taking the above-mentioned parts by weight raw materials specifically includes the following steps:

[0078] Pretreatment, chemical compounding, homogenization, sterilization, fermentation, filling, and maturation after storage;

[0079] The pretreatment: the raw milk is inspected and accepted after passing the inspection, and the milk is cleaned by a sterilization separator and then cooled to 2-6°C for storage;

[0080] The compounding of the ingredients: the raw milk is heated to 65-75°C and mixed with white sugar, sta...

Example Embodiment

[0095] Example 3

[0096] A preparation method of cereal meal replacement yogurt, which is prepared from the following parts by weight of raw materials:

[0097] 690 portions of fresh milk, 100 portions of white sugar, 30 portions of cream, 25 portions of oatmeal rice, 20 portions of fruit puree, 10 portions of whey protein powder, 3 portions of stabilizers, 1 portion of food flavor, 0.02 portions of lactic acid bacteria;

[0098] The preparation method for preparing cereal meal replacement yogurt by taking the above-mentioned parts by weight raw materials specifically includes the following steps:

[0099] Pretreatment, chemical compounding, homogenization, sterilization, fermentation, filling, and maturation after storage;

[0100] The pretreatment: the raw milk is inspected and accepted after passing the inspection, and the milk is cleaned by a sterilization separator and then cooled to 2-6°C for storage;

[0101] The compounding of the ingredients: the raw milk is heated to 65-75°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com