Mold core for manufacturing light guide plate and microstructural manufacturing method of mold core

A manufacturing method and microstructure technology, applied in applications, home appliances, optical components, etc., can solve the problems of consumption, excessive production costs and man-hours, and the nickel layer is easily damaged, and achieve the effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of an embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

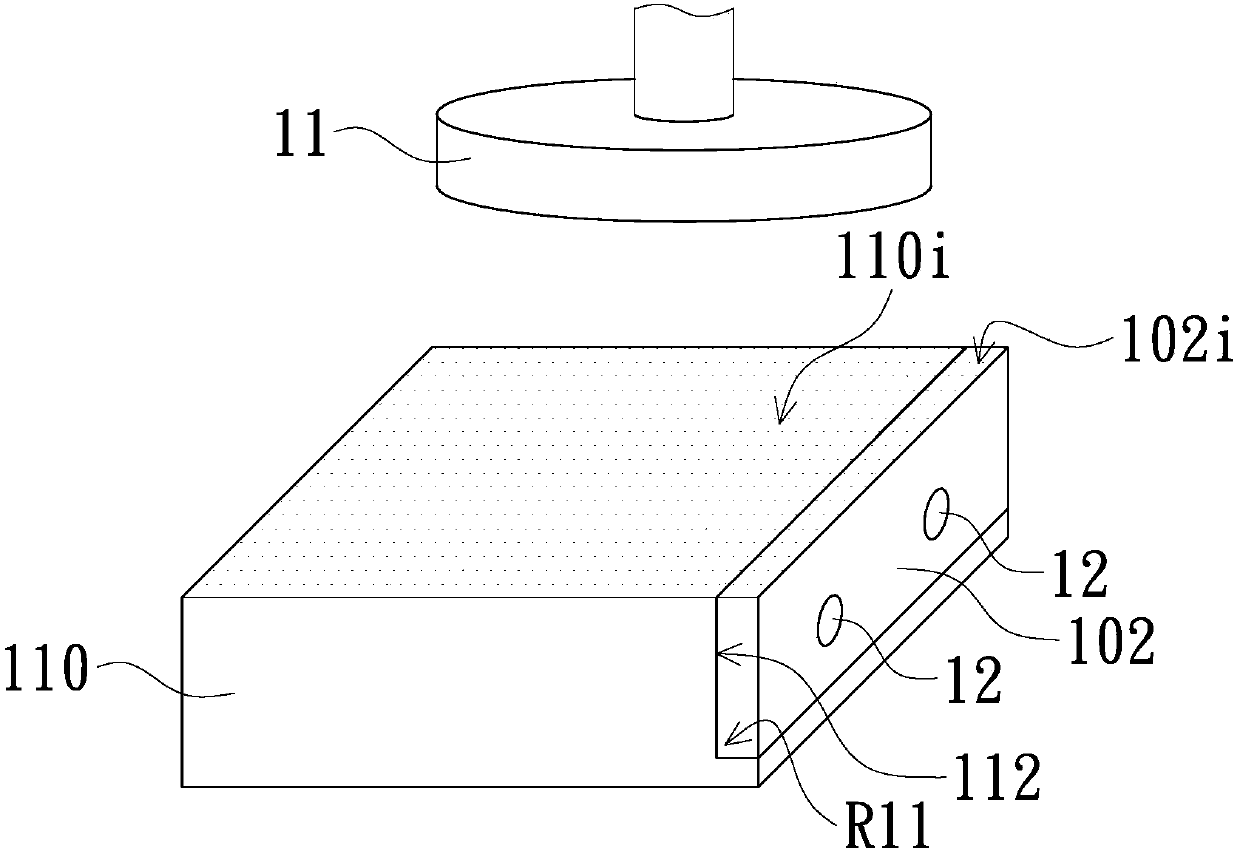

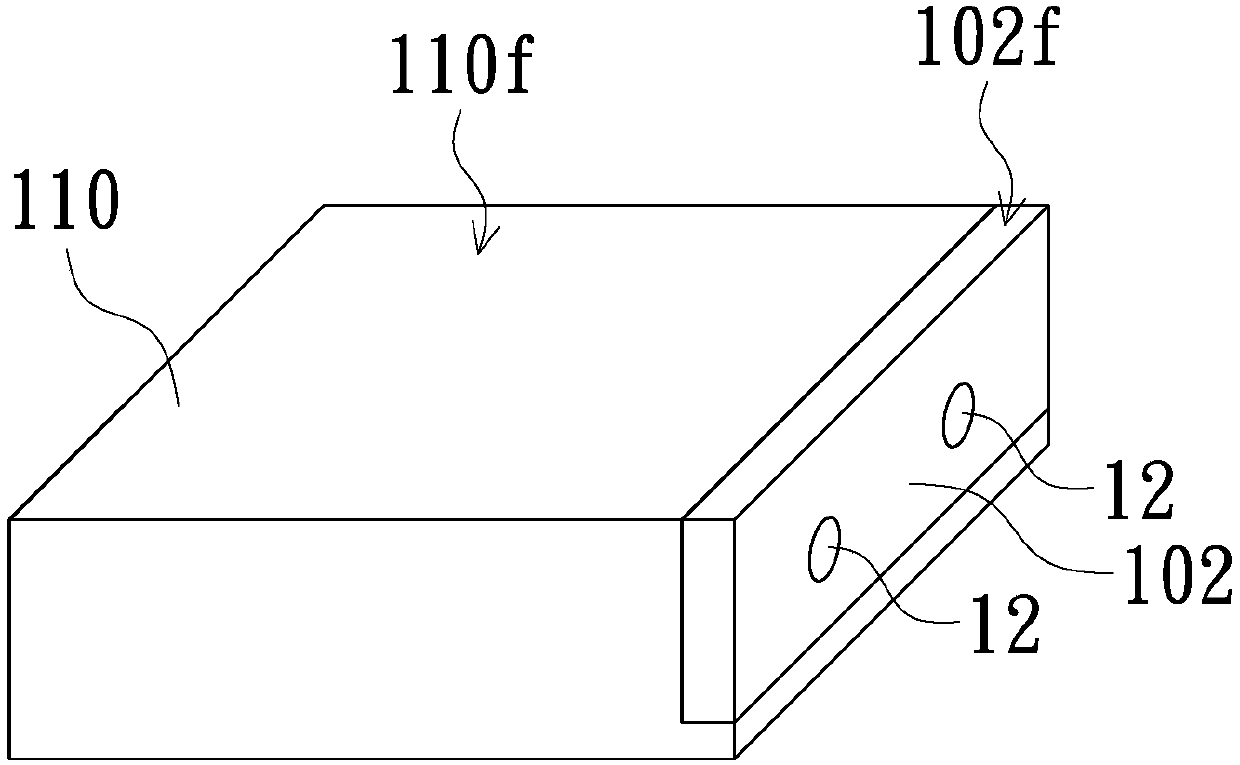

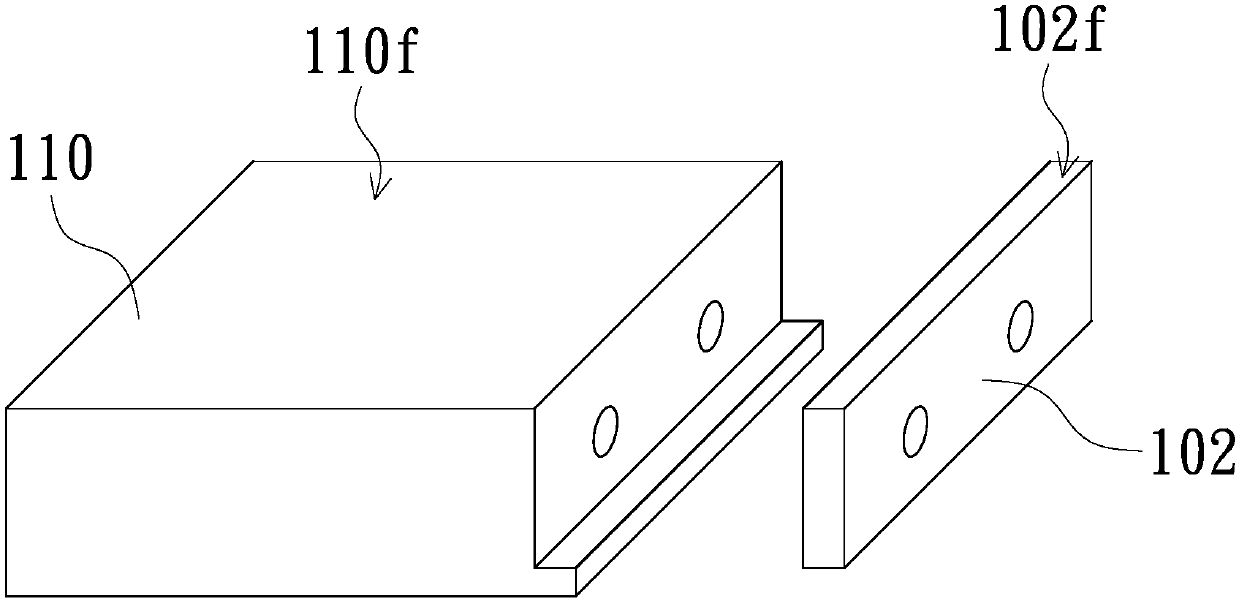

[0017] Figure 1A to Figure 1H It is a three-dimensional schematic view of the manufacturing method of the mold core microstructure in an embodiment of the present invention. see Figure 1A , in the microstructure manufacturing method of the mold core in this embodiment, firstly, the mold core body 110 and the alignment insert 102 are provided, and the alignment insert 102 is mounted on the mold core body 110 . by Figure 1A For example, the alignment insert 102 can be connected by at least one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com